Speed control under Real sensorless vector control, vector control, PM sensorless vector

control

196

PARAMETERS

NOTE

• When adjusting the gain manually, set Pr.819 Easy gain tuning selection to "0" (no easy gain tuning) (initial value).

• Pr.830 Speed control P gain 2 and Pr.831 Speed control integral time 2 are valid when terminal RT is ON. In this case,

replace them for Pr.820 and Pr.821 in the description above.

When using a multi-pole motor (8 poles or more)

• If the motor inertia is known, set Pr.707 Motor inertia (integer) and Pr.724 Motor inertia (exponent). (Refer to page 442.)

• Under Real sensorless vector control or vector control, adjust Pr.820 Speed control P gain 1 and Pr.824 Torque control

P gain 1 (current loop proportional gain) to suit the motor, by referring to the following methods.

• Setting the parameter of Pr.820 Speed control P gain 1 higher speeds up the response, but setting this too high causes

vibration and acoustic noise.

• Setting the parameter of Pr.824 Torque control P gain 1 (current loop proportional gain) too low causes current ripple,

and a noise synchronous with this will be emitted from the motor.

• Adjustment method:

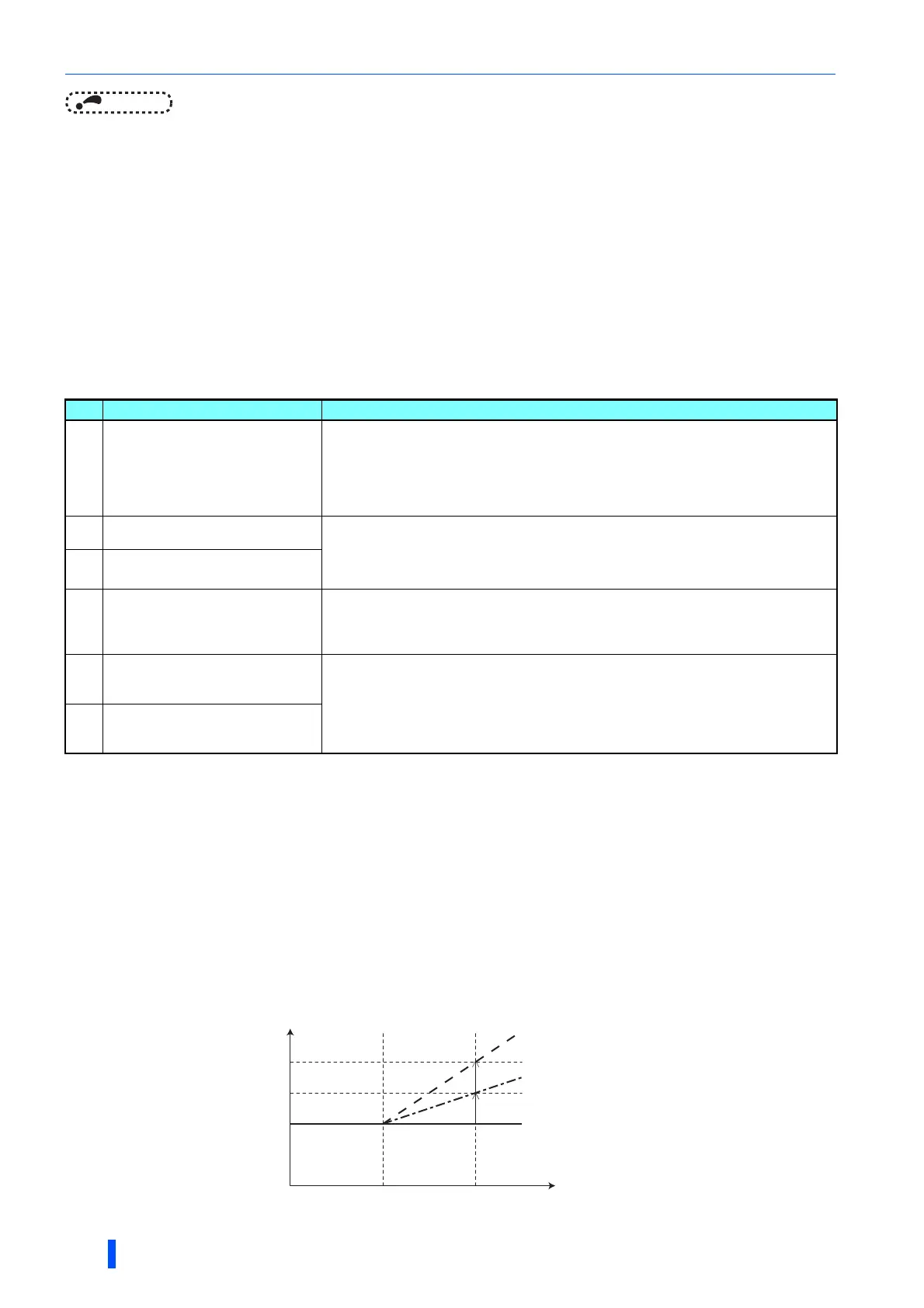

Compensating the speed control P gain in the constant output range

(Pr.1116)

• In the constant output range (rated speed or higher), the response of speed control is reduced due to weak field. Thus, the

speed control P gain is needed to be compensated using Pr.1116 Constant output range speed control P gain

compensation.

•In Pr.1116, set a compensation amount for the doubled rated speed regarding the speed control P gain at the rated speed

or lower as 100%.

(Speed control P gain at rated speed or higher) = (Speed control P gain at rated speed or lower) (100% + compensation

amount)

Compensation amount = Pr.1116 / Rated speed (Speed - Rated speed)

No. Movement condition Adjustment method

1

Motor rotation speed in the low-speed

range is unstable.

Pr.820 Speed control P gain 1 must be set higher according to the motor inertia. For multi-

pole motors, because the inertia of the motor itself tends to be large, first perform broad

adjustment to improve the unstable movements, and then perform fine adjustment by

referring to the response level based on this setting.

Also, for vector control, gain adjustment appropriate for the inertia can be easily performed

by using easy gain tuning (Pr.819=1).

2 Rotation speed trackability is poor.

Set Pr.820 Speed control P gain 1 higher. Raise the setting by 10%s and set a value that

satisfies the following condition: The setting immediately before vibration/noise starts

occurring 0.8 to 0.9. If it cannot be adjusted well, double Pr.821 Speed control integral

time 1 and perform the adjustment of Pr.820 again.

3

Large fluctuation of the rotation speed

relative to load fluctuation.

4

Torque shortage or motor backlash

occurs when starting or passing a

low-speed range under Real

sensorless vector control.

Set the speed control gain higher. (The same as No.1.)

If this cannot be prevented through gain adjustment, raise Pr.13 Starting frequency for a

fault that occurs when starting, or shorten the acceleration time and avoid continuous

operation in a low-speed range.

5

Unusual vibration, noise and

overcurrent of the motor or machine

occurs.

Set Pr.824 Torque control P gain 1 (current loop proportional gain) lower. Lower the

setting by 10%s and set a value that satisfies the following condition: The setting

immediately before the condition improves 0.8 to 0.9.

6

Overcurrent or overspeed (E.OS)

occurs when starting under Real

sensorless vector control.

Speed

100%

0%

200%

Rated speed Rated speed×2

Pr.1116=100%

Pr.1116=0%(Initial value)

Pr.1116=50%

Ratio multiplied to

speed control P gain

150%

Loading...

Loading...