Speed control under Real sensorless vector control, vector control, PM sensorless vector

control

PARAMETERS

199

5

Pr.3 Base frequency, Pr.19 Base frequency voltage page 598

Pr.72 PWM frequency selection page 277

Pr.80 Motor capacity, Pr.81 Number of motor poles page 164

Pr.125 Terminal 2 frequency setting gain frequency, Pr.126 Terminal 4 frequency setting gain frequency page 415

Pr.359 Encoder rotation direction, Pr.369 Number of encoder pulses page 62

Pr.822 Speed setting filter 1 page 413

Pr.824 Torque control P gain 1 (current loop proportional gain) page 225

5

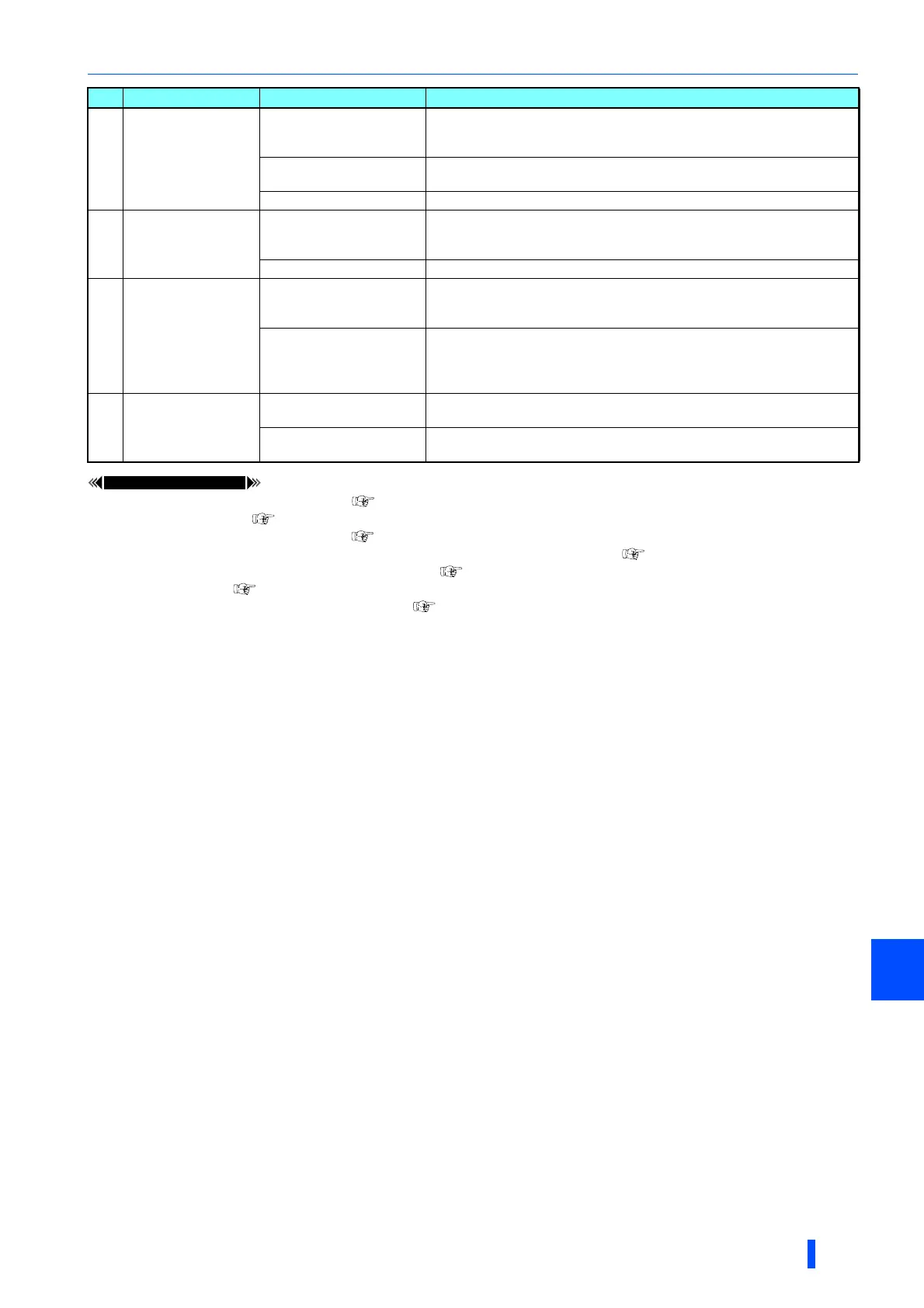

Hunting (vibration or

acoustic noise) occurs

in the motor or the

machine.

Speed control gain is too

high.

• Perform easy gain tuning.

•Set Pr.820 lower and Pr.821 higher.

• Perform speed feed forward control or model adaptive speed control.

Torque control gain is too

high.

•Set Pr.824 Torque control P gain 1 (current loop proportional gain)

lower.

Motor wiring is incorrect. • Check the wiring.

6

Acceleration/

deceleration time is

different from the

setting.

Torque shortage.

• Raise the torque limit.

(Refer to the torque limit for speed control on page 185.)

• Perform speed feed forward control.

Load inertia is too high. • Set acceleration/deceleration time suitable for the load.

7

Machine movement is

unstable.

Speed control gain is not

suitable for the machine.

• Perform easy gain tuning.

• Adjust Pr.820 and Pr.821.

• Perform speed feed forward control or model adaptive speed control.

Response is slow because

of the inverter's

acceleration/deceleration

time setting.

• Set the optimum acceleration/deceleration time.

8

Rotation ripple occurs

during the low-speed

operation.

High carrier frequency is

affecting the motor rotation.

•Set Pr.72 lower.

Speed control gain is too

low.

•Set Pr.820 higher.

No. Condition Cause Countermeasure

Loading...

Loading...