April 2017

1-5

Xerox® VersaLink® B7025/B7030/B7035 Multifunction Printer

SCP 4

Service Call Procedures

Launch Issue

SCP 4 Subsystem Maintenance

Use Subsystem Maintenance to identify potentially worn components that should be replaced

to prevent further faults, and to perform routine cleaning and lubrication of the machine.

Procedure

WARNING

Switch off the electricity to the machine, GP 10. Disconnect the power lead from the

customer supply while performing tasks that do not need electricity. Electricity can

cause the death or injury. Moving components can cause the injury.

Go to the correct procedure:

• Service Checks

• Installation of New Parts

• HFSI

• How to Clean the Machine

• Drum Cartridge Handling

Service Checks

Perform the actions in Table 1 at the indicated service interval.

Installation of New Parts

The design life of the major components is shown in Table 2.

HFSI

For High Frequency Service Items (HFSI), refer to dC135 CRU/HFSI Status.

How to Clean the Machine

Use a dry lint free cloth or a lint free cloth moistened with water for all cleaning unless directed

otherwise. Wipe with a dry lint free cloth if a moistened cloth is used.

1. Feed Components (Rolls and Pads)

Use a dry lint free cloth or a lint free cloth moistened with water. Wipe with a dry lint free

cloth if a moistened cloth is used.

2. Toner Dispense Units

Vacuum the toner dispense units.

3. Jam Sensors

Clean the sensors with a dry cotton swab.

4. Scanner

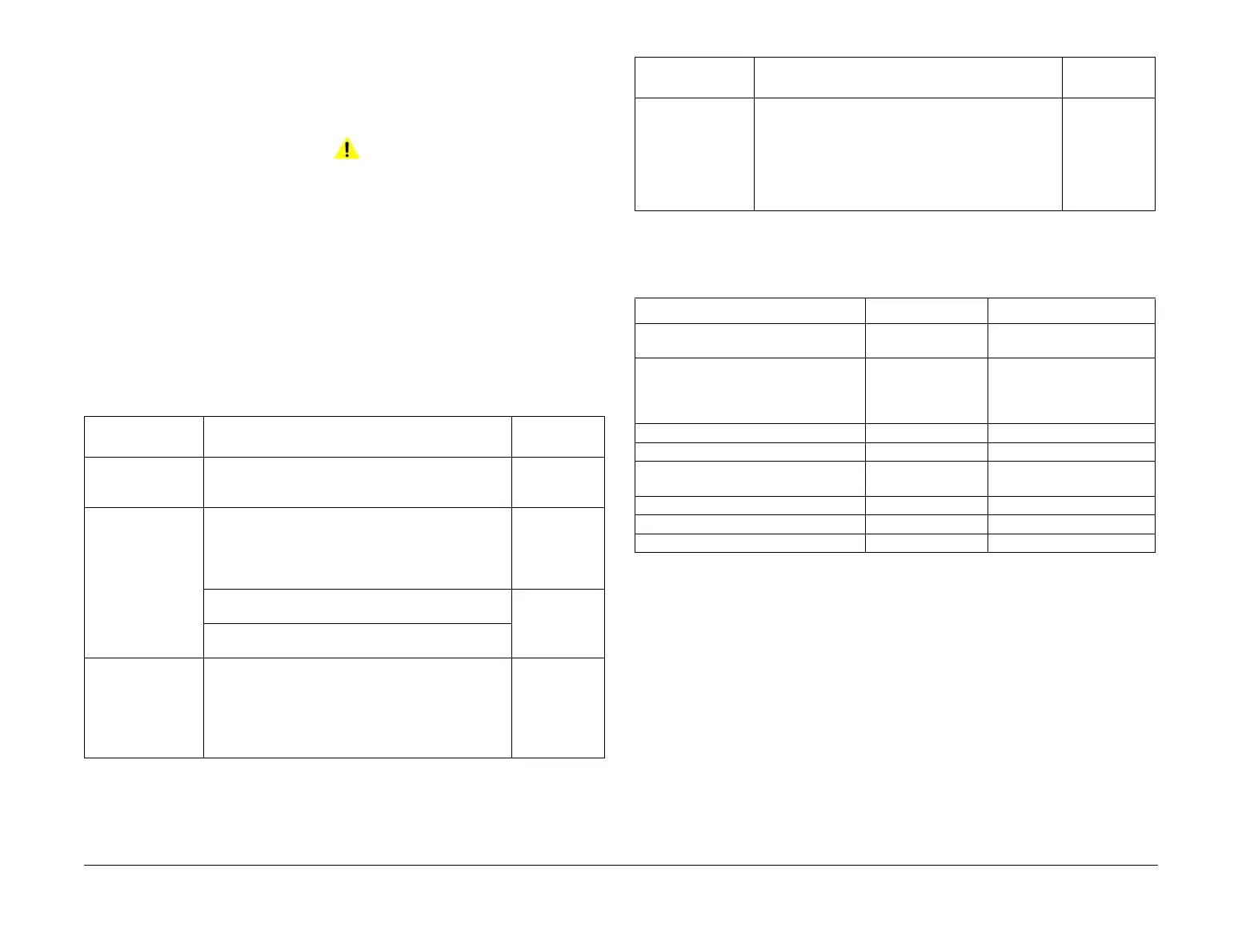

Table 1 Service actions

Servicing Items Service Details

Service

Interval

IQ check Check the overall copy quality using a test chart.

Check for uneven density, blank areas, drum

scratches, heat roll scratches, etc. in A3 halftone.

Every visit

Clean the machine

interior

Check and clean the paper transport roller (including

the bypass tray).

Clean any toner residue in the paper transport path.

Clean any contamination and paper dust from the jam

sensors.

300K feeds

Clean the operating parts around the toner cartridge,

PL 90.05 Item 1 and drum cartridge, PL 90.20 Item 1.

Every visit

Use the cleaning tool, stored in the front door, to clean

the print head assembly, PL 60.35 Item 1.

Clean the optics

and DADF

1. Clean the document cushion, PL 5.05 Item 1.

Use an optical cleaning cloth to clean the surface

of the document glass, PL 60.10 Item 9 and the

CVT glass, PL 60.10 Item 8.

2. Clean the DADF nudger and feed rolls, PL 5.25

Item 2 and the retard roll, PL 5.65 Item 4.

1. Every visit

2. 10K feeds

Safety Check Ensure that the power cords are not cracked and no

wires are exposed.

Ensure that an extension cord with insufficient length

or power cord outside the specification, such as an off-

the-shelf power strip, is being used.

Ensure that a single socket does not have multiple

power plugs plugged into it.

Every visit

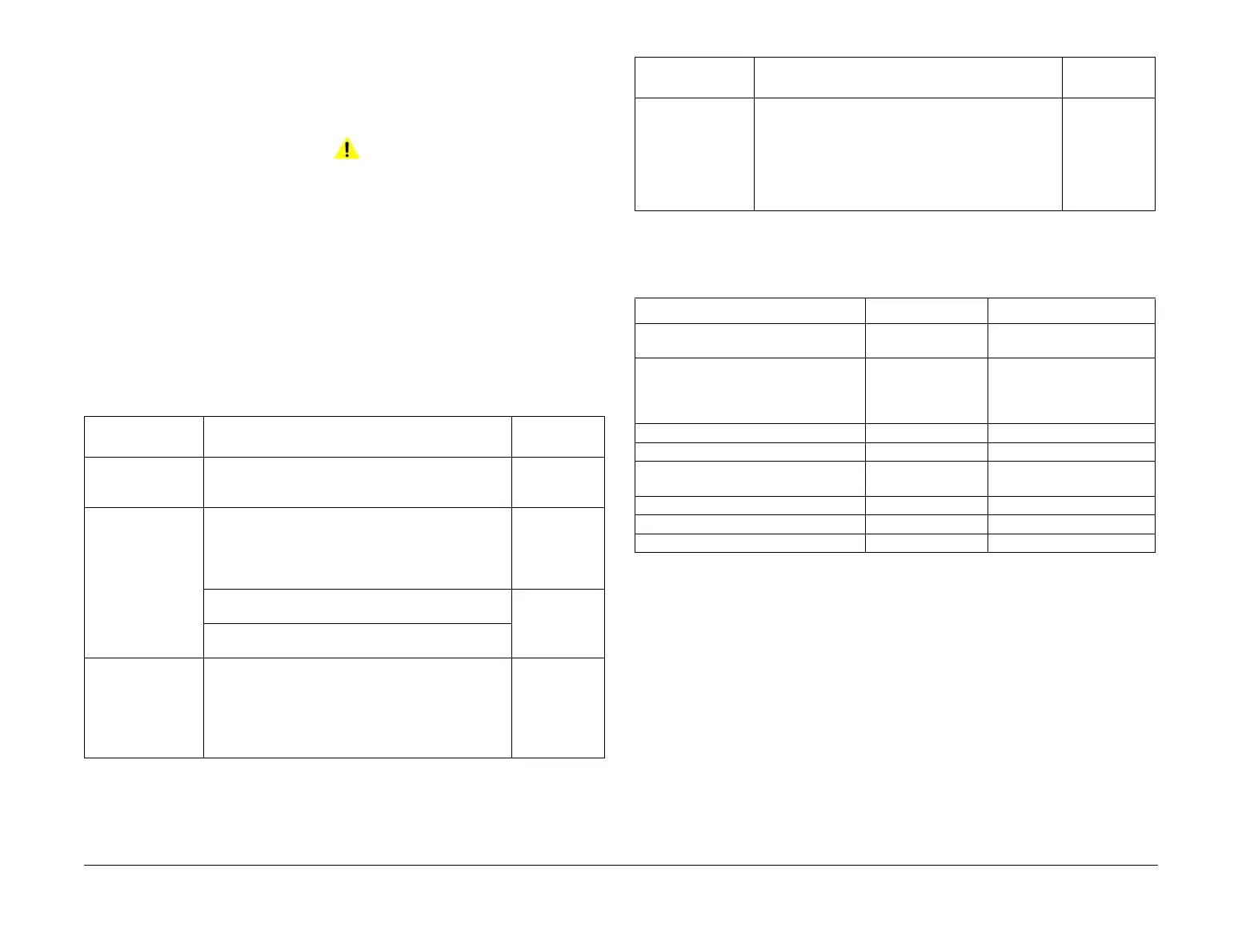

Table 2 Design life

Part Life PL Ref.

DADF feed, nudger and retard rolls 200K feeds PL 5.25 Item 2 and PL 5.65

Item 4

Fuser 175K prints or when

IOT power on time

exceeds 18,000,000

seconds.

PL 10.05 Item 2

Drum cartridge 80K feeds PL 90.20 Item 1

Tray 1 feed, nudger and retard rolls 300K feeds PL 80.11

Bypass tray feed and nudger rolls and

retard pad

50K feeds PL 70.40

Tray 2 feed, nudger and retard rolls 300K feeds PL 80.25

Tray 3 feed, nudger and retard rolls 300K feeds PL 80.25

Tray 4 feed, nudger and retard rolls 300K feeds PL 80.25

Table 1 Service actions

Servicing Items Service Details

Service

Interval

Loading...

Loading...