ASDA-A2 Chapter 8 Parameters

Revision February, 2017 8-179

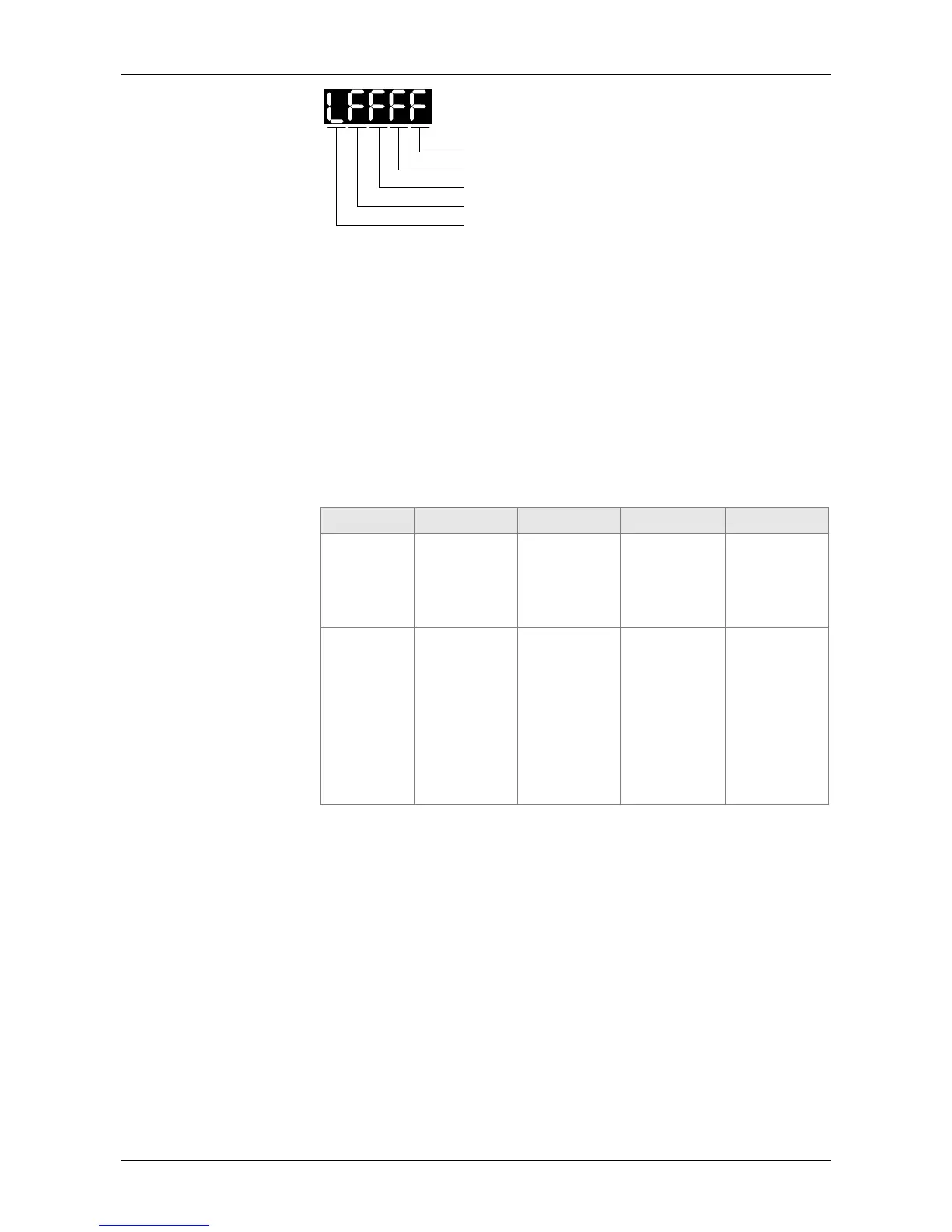

Settings:

X

Y

Z

U

Low word

X: See the following table

Y: 0-CAPTURE is not working

1-AUX ENC (linear scale) is set as the source

2-PULSE Cmd

3-Main ENC (main encoder)

When the source of CMP is CAP axis, the source Y of CAP cannot

be changed.

Z: 0-NO, 1-NC

U: trigger the minimum interval (Unit: ms)

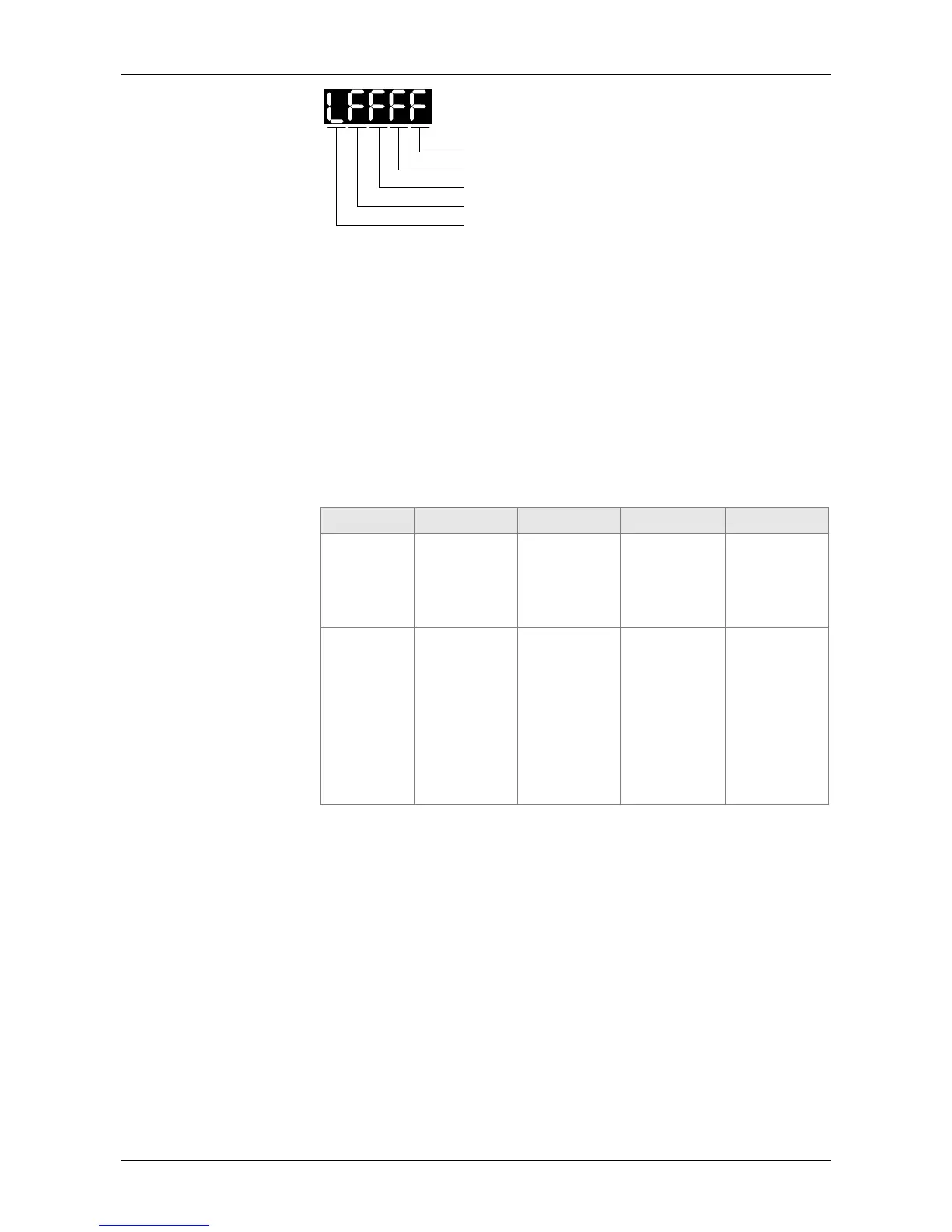

bit 3 2 1 0

X function Execute PR

when

finishing

capturing

After

capturing the

first data,

CMP is

activated.

Reset the

position of

the first data

Activate CAP

Description Execute PR

#50 after

finishing CAP

It is invalid

when CMP is

activated.

After

capturing the

first data,

reset the

position

coordinate

Starts to

capture when

it is set to 1.

After

finishing

capturing,

this bit

becomes 0

automatically

.

bit 0: When the value set by P5-38 is bigger than 0, set bit 0 to 1 will

activate CAP function and DO.CAP_OK is OFF. Every time,

when a data is captured, the value of P5-38 will minus one. When

the P5-38 is 0, it means the capture function is completed,

DO.CAP_OK is ON and bit 0 will be reset to 0 automatically. If

P5-38 equals to 0, set bit 0 to 1 will not activate CAP function.

DO.CAP_OK is OFF and bit 0 will automatically be set to 0. If

CAP function is activated, it cannot set 1 to bit 0. It only can be

written 0 to disable CAP function.

bit 1: If this bit is 1, when capturing the first data, the current position of

CAP axis will be set to the value of P5-76.

bit 2: If this bit is 1, when capturing the first data, CMP will be activated.

(When bit 0 of P5-59 is set to 1 and P5-58 is set to the previous

value.) If CMP has been activated, then this function is invalid.

bit 3: If this bit is 1, as soon as the CAP finished, PR procedure #50 will

be triggered automatically.

Loading...

Loading...