9 Field-IQ system setup Control setup

Layout

At the Layout tab, enter information about the implement that will be used to apply the material.

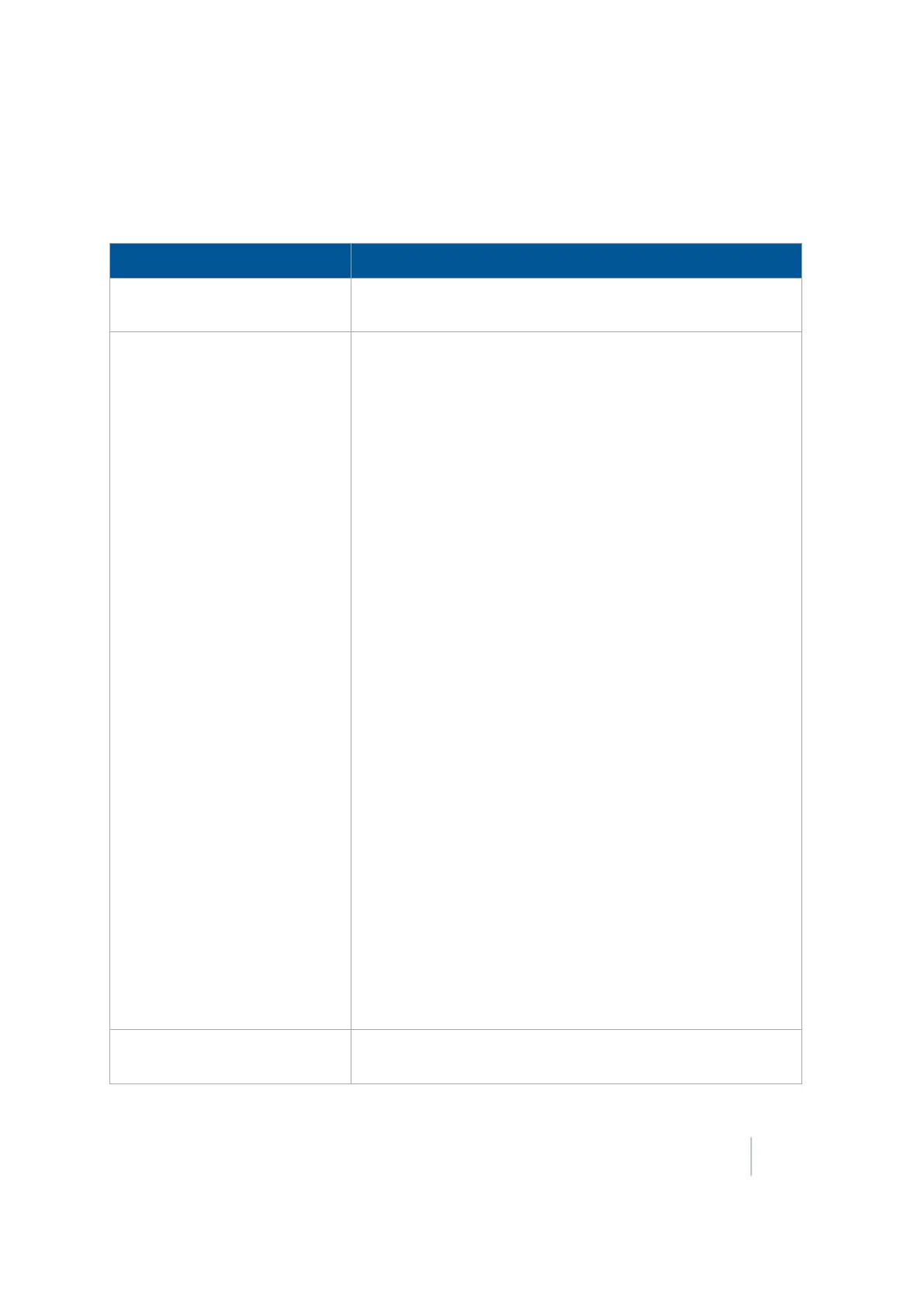

Setting Explanation

Location Name Add a name to the Control Location, for example, Hoppers, Front

Bin, Rear Bin, Left Saddle Tanks.

Bin / Tank Setup The system tracks how much material is left in the bin/tank,

and provides a warning when the bin/tank needs to be refilled.

Adjust the settings for:

l Status:

ll On: The system tracks the bin/tank level and provide

warnings.

l Off: The system will not track the bin/tank level or

provide warnings.

l

Density: (Granular and granulated material only.) Used in

system setup and calibration to ensure accuracy in

applying product. When changing material this setting

must be updated.

l Capacity Units: Select Default Units or Bushels. Default units

will vary according to the type of material that is being

applied.

l

Bin Capacity: The amount the tank/bin holds when full.

Note –

Markings on tank/bin may not be accurate.

l Current Volume: Current volume of the product in the tank.

l Partial Refill: The amount of material that will be added to

the bin/tank during a partial refill.

l Warning Level: Setting that triggers a low bin warning. The

level at which a warning displays on the screen when your

bin/tank reaches a set threshold.

l

Spinner Pulses Per Revolution: Enter the number of magnetic

pick up points per revolution of the spinner.

l Refill Tank/Bin: Refills the tank/bin to capacity.

l Partial Refill Tank/Bin: Refills the tank/bin to the Partial Refill

amount.

Row Offset Setup

Provides additional tuning by detailing where the material will

be applied in relation to the vehicle. Increase coverage

Version 9.25, Revision B FM-1000 Integrated Display User Guide 217

Loading...

Loading...