April 2017

8-25

Xerox® VersaLink® B7025/B7030/B7035 Multifunction Printer

Product Technical Overview

Launch Issue

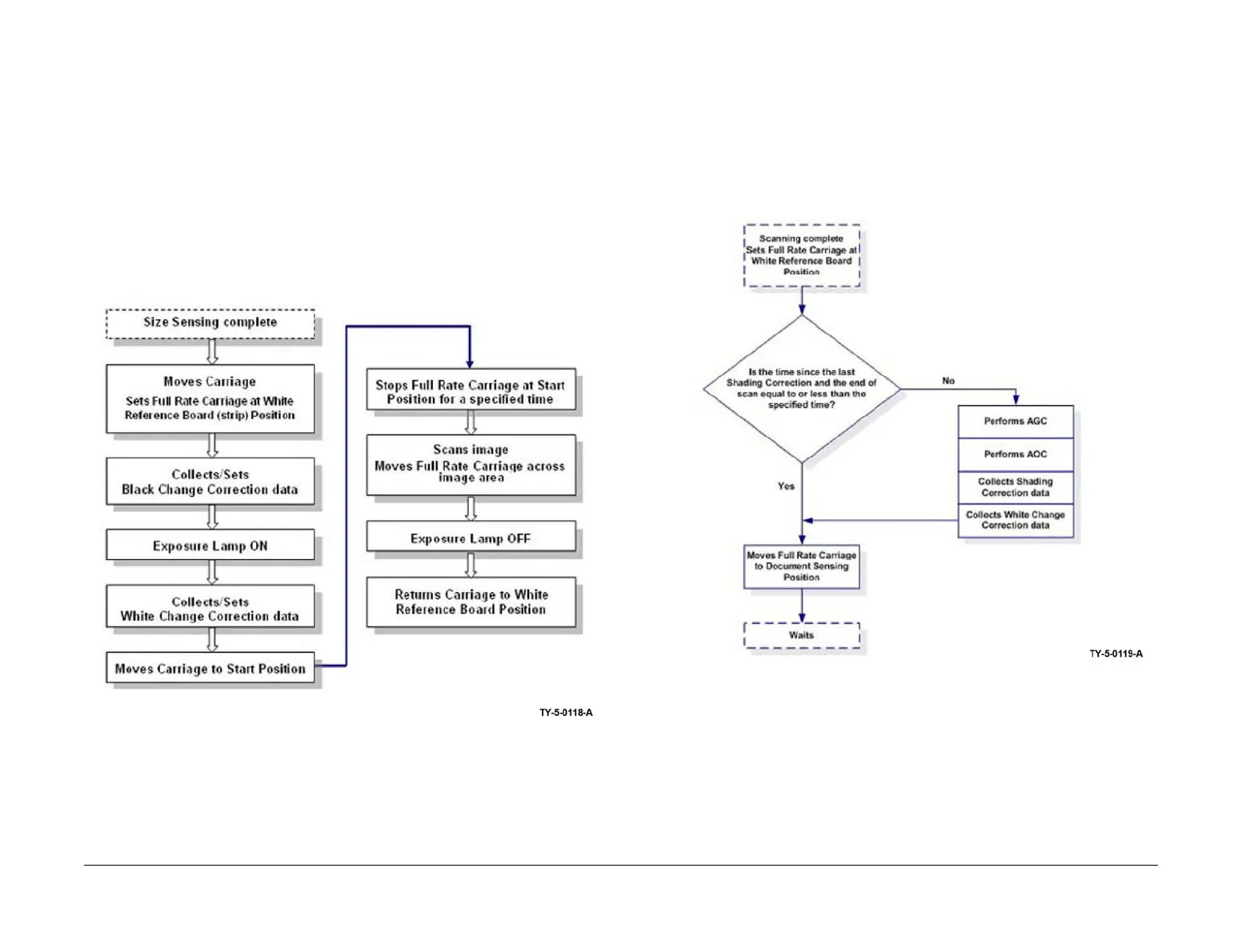

Platen Scanning Operation

The scan process begins once size sensing is complete. First, the full rate carriage moves to

the white reference strip position. Here, with the exposure lamp off, it collects and applies black

change correction data.

Next, the exposure lamp turns on and the IIT collects and applies white change correction

data.

The full rate carriage now moves to the start position, where it waits a specified time. When the

wait time elapses, the full rate carriage moves across the image area.

The exposure lamp turns off at the end of the scan, and the full rate carriage returns to the

white reference strip position. Refer to Figure 11.

Figure 11 Platen scanning operation

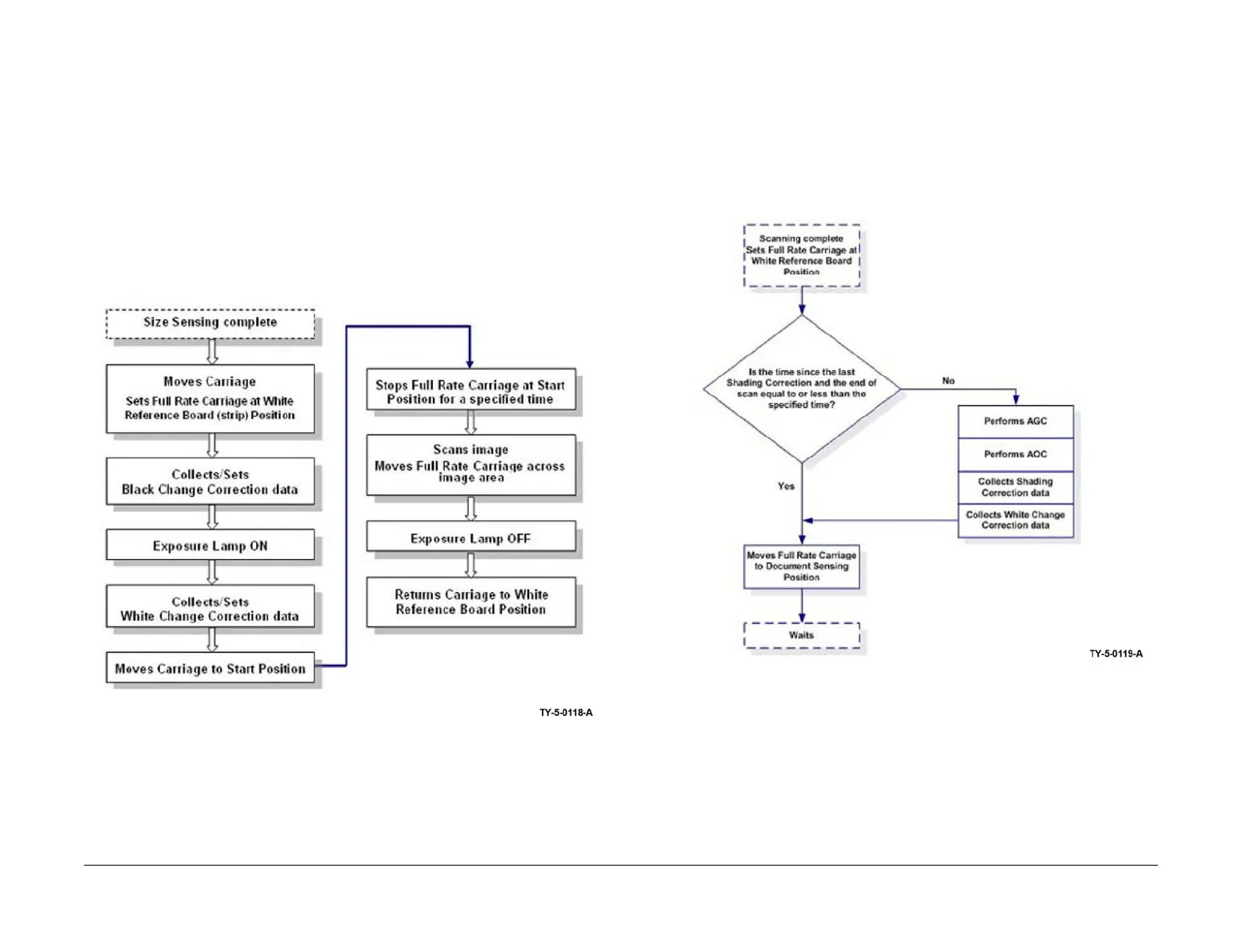

End of Platen Scanning Operations

At the end of the scan, with the full rate carriage at the white reference strip position, the IIT

determines how much time has elapsed since the last shading correction was performed.

If the elapsed time is greater than a specified value, the IIT performs auto gain control and auto

offset control, and collects shading correction data and white change correction data.

It then moves the full rate carriage to the document sensing position, where it waits for the next

customer job. Refer to Figure 12.

Figure 12 End of platen scanning

Loading...

Loading...