IGN ignition angle measurement module 313

imc CANSAS Users Manual - Doc. Version 1.9 - 05.12.2014© 2014 imc Meßsysteme GmbH

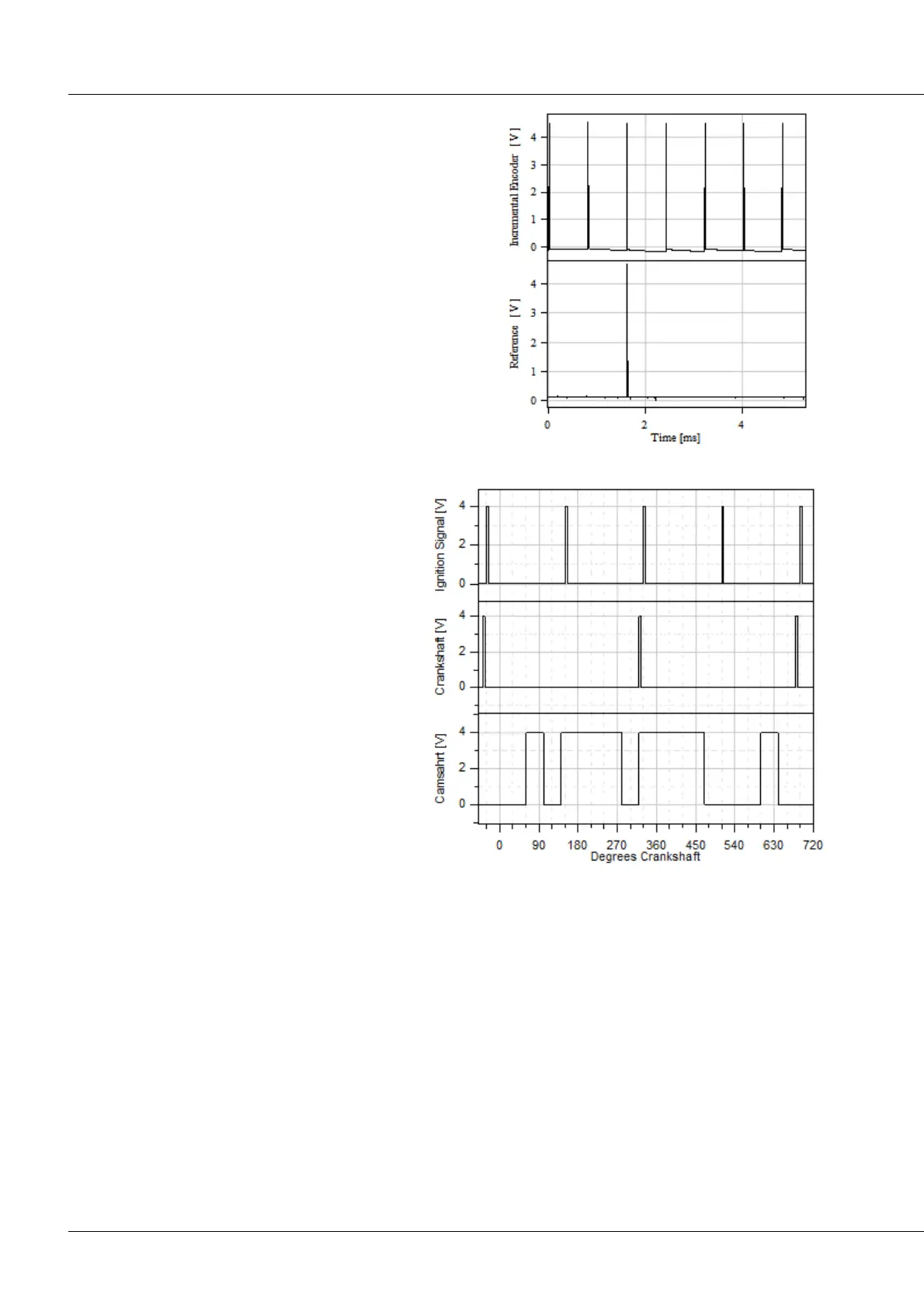

It is also possible to use an incremental counter having an

additional zero output, which is connected to the imc

CANSAS-IGN as the reference signal (REF). The zero

output then indicates the crankshaft's zero marker.

Incremental counter with zero output

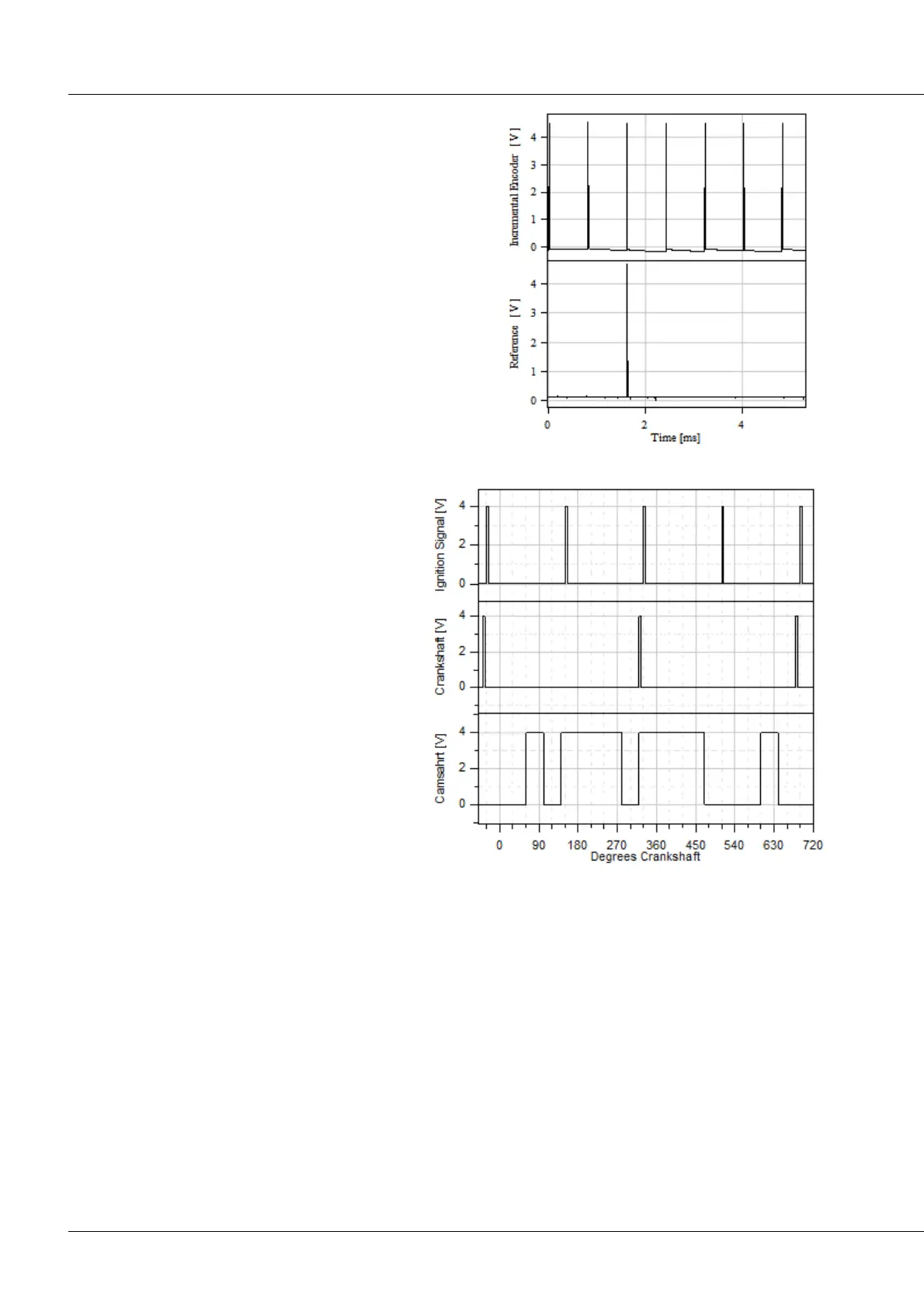

For monitoring selected cylinders, a camshaft

sensor must be connected.

This sensor returns one impulse per revolution

of the camshaft.

Precision

imc CANSAS-IGN captures when the signals cross defined thresholds, at a resolution of fractions of

microseconds. From these data it is possible to calculate the ignition angle with precision of 0.1

crankshaft degree and better, even at high RPMs. Thus, if there even is any imprecision, then it is in

determining the pulse times. This is mostly because the pulses are not steep enough and a threshold

value must be determined. then the threshold selection influences the time when the pulse is detected.

Also, the sensor equipment is subject to transit times which vary with the RPMs and cannot be corrected.

The sensor equipment itself has some imprecision. For instance, cogwheels may not be manufactured

exactly, VRS sensors return RPM-dependent phase shifts. Some of the effects can be compensated by

appropriate parameterization of imc CANSAS-IGN, but some can't.

Loading...

Loading...