6/02

4-173

DC1632/2240

ADJ 9.9, ADJ 9.10

Repairs and Adjustments

Prelaunch Training/Review

Lead Edge Registration for Tray 5 (MSI)

Purpose

NOTE: There are three settings for Tray 5 Lead Edge; one for standard weight paper, one for

heavyweight stock, and one for extra-heavyweight stock.

To correctly set the lead edge of the image in relation to the edge of the paper.

Check

1. Load Tray 5 with the largest standard weight paper used by the customer.

2. Select Tray 5 (MSI) in the Lead Edge column.

3. Press the Start button on the screen. As the prints are made, mark each to indicate the

lead edge.

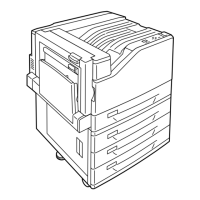

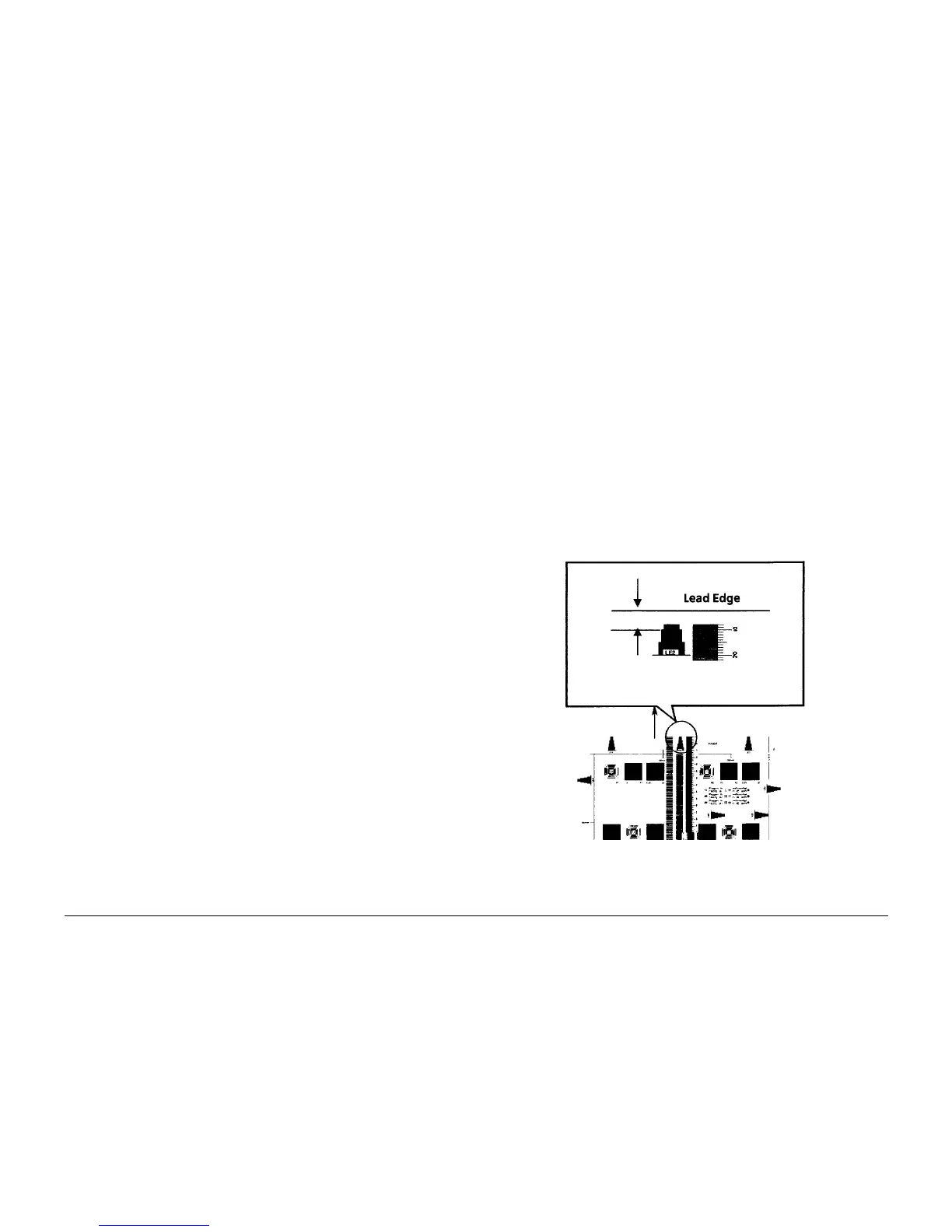

4. Take the third pattern that was printed and measure from the lead edge to point ëAí on Fig-

ure 1 (the intersection of the 7th line from the left edge and the first line from the lead

edge).

5. If the measured value is not 21.6mm±0.5, perform the Adjustment.

6. If the customer uses heavyweight or extra-heavyweight stock, load Tray 5 with the stock.

Select Tray 5 (HW) or Tray 5 (XHW), as appropriate. Repeat the check.

Adjustment

1. Use the Right and Left Arrow buttons to move the image toward or away from the lead

edge of the paper. Each click on the button moves the image 0.25mm. The cumulative

amount of shift is indicated in the Lead Reg. box.

2. After adjusting the registration, click Set Adjust Value.

NOTE: Changes made to the NVM for LE registration are not implemented unless the machine

exits Diagnostic Mode.

3. Go to the Service Exit tab and select Temporary Closeout.

4. After the machine reboots and is ready to copy, reconnect the PWS.

5. Select Start.

6. Repeat the check/adjustment until the specifications are met.

7. Select Save [LR] to save the new NVM settings.

ADJ 9.10 IIT Lead Edge Registration

Purpose

To adjust the IIT scan timing in the Slow Scan direction and to correct the copy position.

Check

CAUTION

Perform this adjustment only if absolutely required; the IIT Lead Edge Registration affects the

precision of the document size detection.

NOTE: Before performing this procedure, make sure that the IOT Lead Edge Registration is

correct. Refer to ADJ 9.9, IOT Side/Lead Edge Registration.

1. Place the Geometric Test Pattern on the Platen Glass correctly and make a copy with the

following settings:

ï Copy Mode: Black

ï Paper Size: 11 x 17 in or A3

ï Magnification: 100%

ï No. of Copies: 2

2. On the 2nd copy, check that the distance from the lead edge to the top of Step 3 on the

LE2 scale is 10.0mm +/- 2.1mm (Figure 1).

Figure 1 Checking IIT Side Registration

3. If the value is not within the specified range, Perform the Adjustment:

Lead Edge

10.0mm

+/- 2.1mm

Loading...

Loading...