2.43

Date Code 20170927 Instruction Manual SEL-751 Relay

Installation

Arc-Flash Protection: System Installation

clearance and creepage requirements. Sensors should be permanently affixed

through the use of supplied mounting grommets or permanent cable ties.

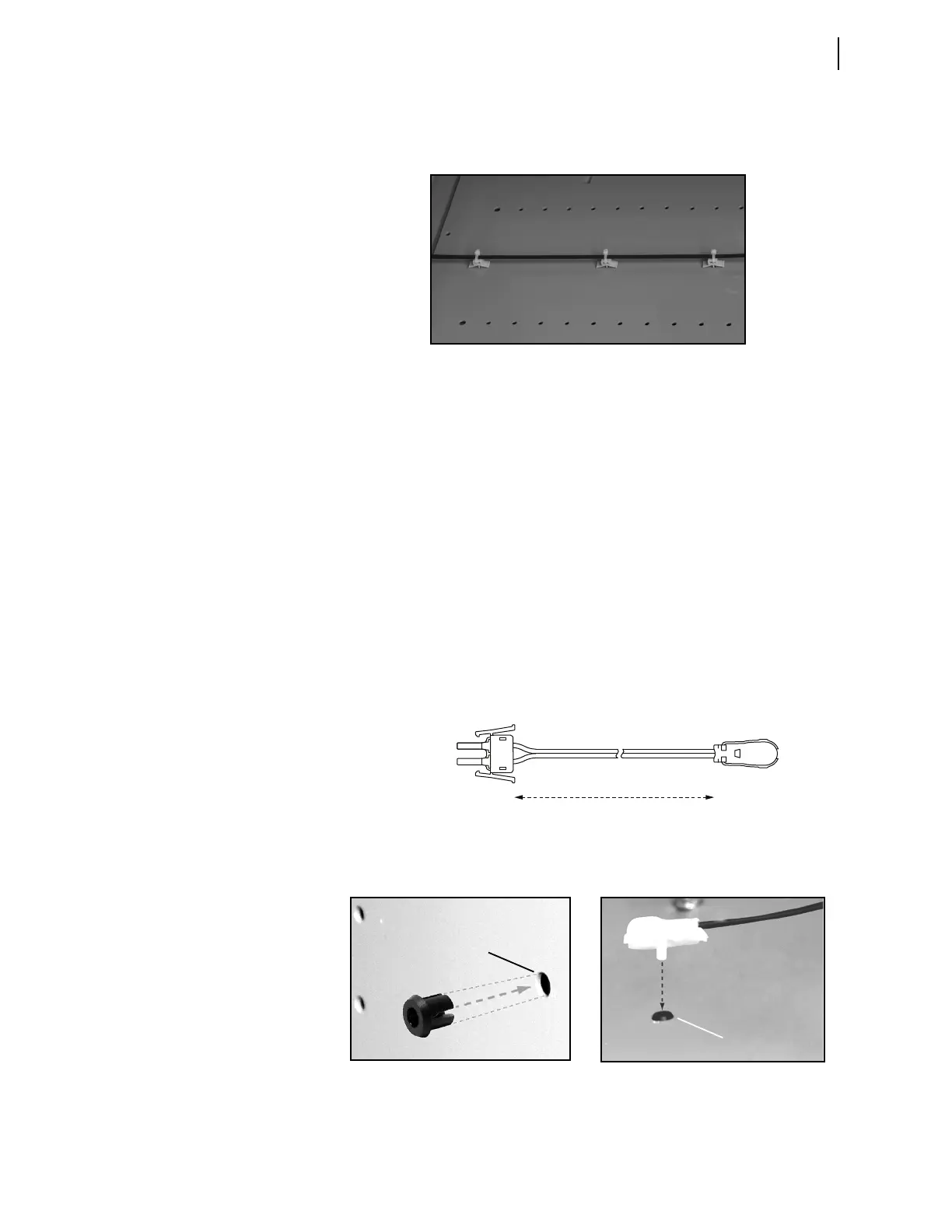

Figure 2.34 shows an example of a typical black-jacketed fiber installation.

Figure 2.34 Black-Jacketed Fiber installation Example

Fiber-bending radius must be kept greater than 50 mm (2 in). Care should be

exercised when crossing from a moving part (such as control cabinet door) to

a stationary switchgear enclosure. Use standard wiring practices with bundled

fibers and well-defined strain relief points. Additional attention is necessary

to prevent moving parts, such as a breaker truck assembly, from inadvertently

damaging the arc-flash sensor fibers. Although easily detected by the sensor

diagnostics, such problems can be eliminated through careful installation

planning. Once routed, fiber sensors are connected to the SEL-751 as shown

in Figure 2.33.

Point-Sensor

Installation

The point-sensor is optimized for monitoring confined switchgear spaces

where the distance between sensors and the potential sources of arc (ener-

gized parts) can be kept below 2 m. Such spaces typically include breaker

compartments, outgoing and incoming cable compartments, and potential

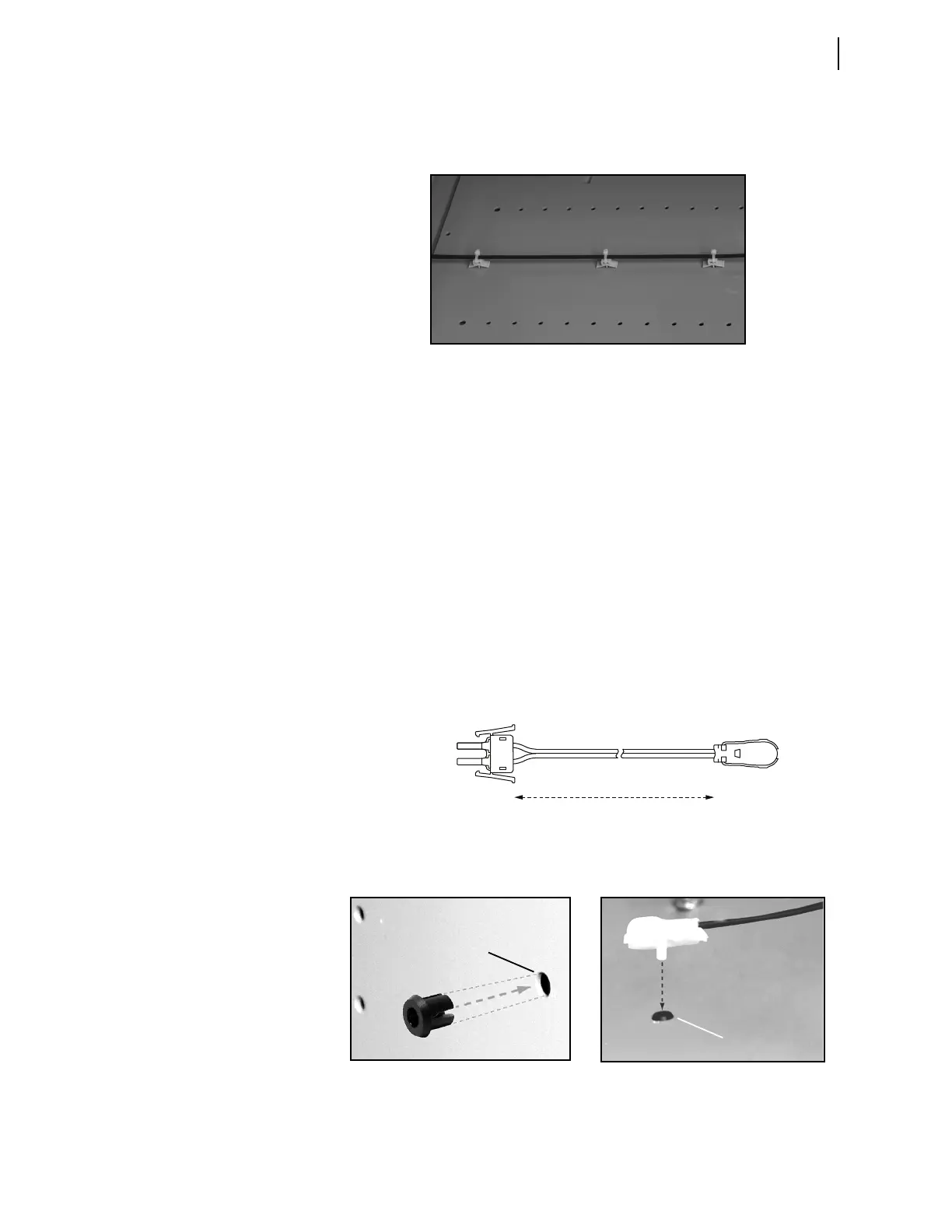

transformer (PT) compartments. Figure 2.35 shows a schematic diagram of

the point-sensor assembly.

Figure 2.35 Point-Sensor Assembly

The sensor is mounted flush on the switchgear cabinet wall, using a standard

1/4-inch hole. Mounting steps are shown in Figure 2.36.

Figure 2.36 Point-Sensor Installation

1. Mounting Grommet Insertion

(1/4” diameter hole)

2. Sensor Insertion

(1/4” diameter hole)

Black-Jacketed Fiber Zipcord Duplex

V-Pin

Terminators

Dual V-Pin

Latch

Sensors

1–35 Meters

Loading...

Loading...