6/02

6-72

DC1632/2240

dC330

Prelaunch Training/Review

General Procedures and Information

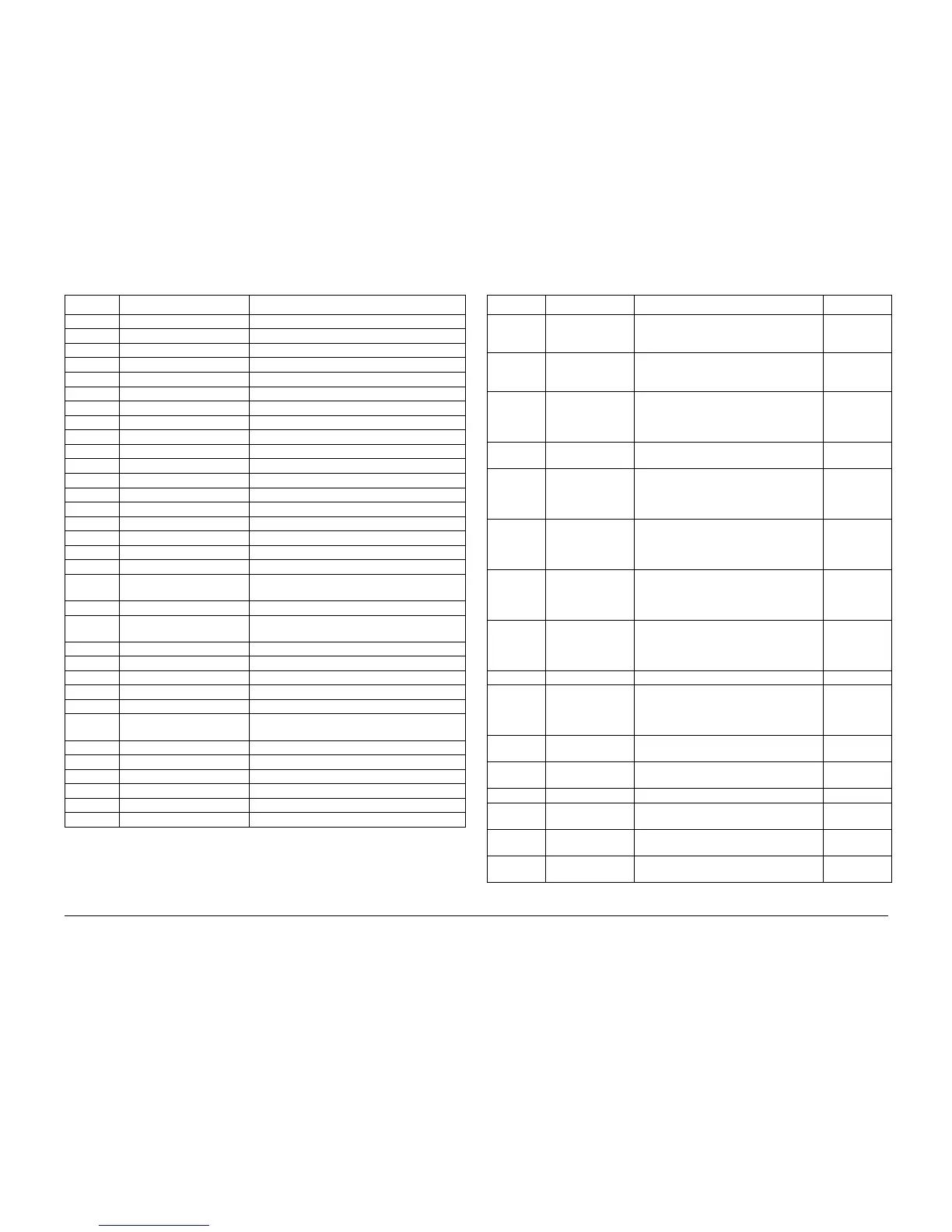

009-153 #C_CRU detect CRU is installed

009-154 #K_CRU detect CRU is installed

009-200 2nd BTR Retract Sensor RetractiON. ON: Low

009-201 POB Sensor Paper detected ON: Low

009-203 1st BTR Retract Sensor RetractiON. ON: Low

010-101 Fuser Exit Paper detected ON: High

010-102 Full Paper Stack Sensor NotFull ON: Low

010-103 Face Up Exit Sensor Paper detected ON: High

012-100 IOT Regi Clutch Clutch OFF ON: High

012-101 Compiler Tray Exit Sensor Paper detected ON: High

012-102 Compiler Paper Sensor Paper detected ON: High

012-103 H-Tra Ent. Sensor Paper detected ON: High

012-104 H-Tra Exit Sensor Paper detected ON: High

012-200 Stacker Paper Sensor Paper detected ON: High

012-201 Stacker Height Sensor Higher than the detection surface ON: High

012-202 Stacker Upper Limit Sensor Upper Limit position. ON: High

012-204 Stacker Stack A Sensor Non-transmissive position. ON: High

012-205 Stacker Stack B Sensor Non-transmissive position. ON: High

012-207 [PWS Display] Staple Head

Home Sensor

Not at Home position. ON: High

012-208 Low Staple Switch Low Staple ON: High

012-209 [PSW Display] Staple Ready

Sensor

Not at Ready position. ON: High

012-210 Eject Clamp Home Sensor Not at Home Position (Roller is DOWN) ON: High

012-211 Set Clamp Home Sensor Not at Home Position (transmissive) ON: High

012-212 Rear Tamper Home Sensor Home position. ON: High

012-215 H-Tra IOT Full Paper Sensor No paper ON: High

012-216 Front Tamper Home Sensor Home position. ON: High

012-217 Decurler Cam Position Sen-

sor

Not at Home Position (transmissive) ON: High

012-224 Stapler Move Sensor Non-transmissive position. ON: High

012-225 Stapler Front Corner Sensor Front Corner position. ON: High

012-300 Front Cover Interlock Switch Open ON: High

012-301 Top Cover Interlock Switch Open ON: High

012-302 Docking Interlock Sensor Docking release ON: High

012-305 H-Tra Interlock Sensor Open ON: High

Table 1 Input Component Control Codes

Code Name Description

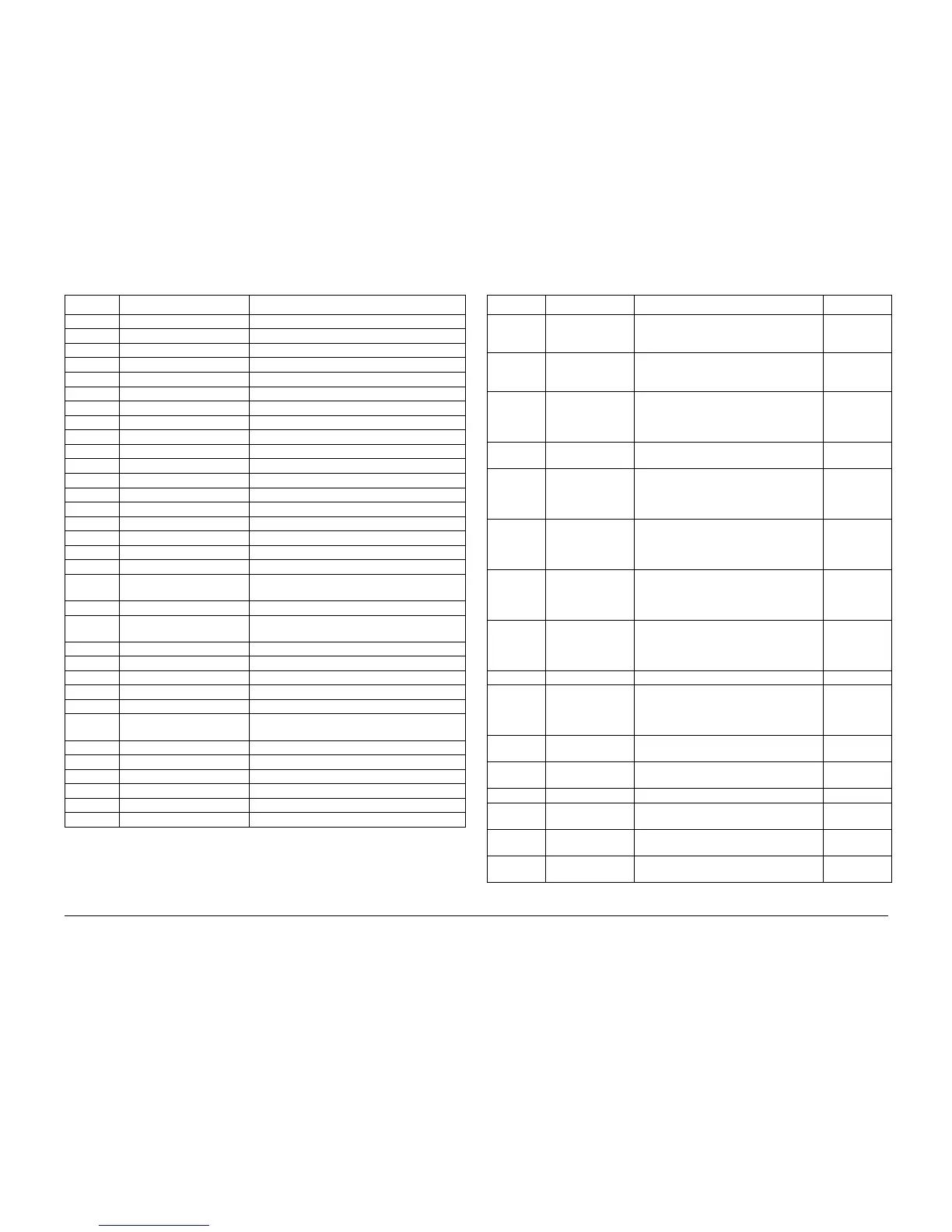

Table 2 Output Component Control Codes

Code Name Description Conflicts

004-001 Steering Motor Reswitch the Steering Cam to Home posi-

tion. ONce and operate it at half cycle after

that.

004-005

004-002 IBT Motor (104mm/

sec)

Operate with the IBT unit removed. The

Belt might be damaged since the Belt Work

Control is not performed.

004-012, 004-

013

004-004 Main Motor

(104mm/sec)

Rotate at medium speed. Operate the

motor with the 2nd BTR nipped, or the LH

Cover opened. Otherwise, the 2nd BTR

might damage the teeth.

004-007, 004-

008

004-005 Steering Motor

Home Position

ON: Low 004-001

004-007 Main Motor (52mm/

sec)

Rotate at half speed. Operate the motor

with the 2nd BTR nipped, or the LH Cover

opened. Otherwise, the 2nd BTR might

damage the teeth.

004-004, 004-

008

004-008 Main Motor

(194mm/sec)

Rotate at double speed. Operate the motor

with the 2nd BTR nipped, or the LH Cover

opened. Otherwise, the 2nd BTR might

damage the teeth.

004-004, 004-

007

004-012 IBT Motor (52mm/

sec)

Rotate at half speed. Operate with the IBT

unit removed. The Belt might be damaged

since the Belt Work Control is not per-

formed.

004-012, 004-

013

004-013 IBT Motor (194mm/

sec)

Rotate at double speed. Operate with the

IBT unit removed. The Belt might be dam-

aged since the Belt Work Control is not per-

formed.

004-002, 004-

012

004-014 IBT_5V ON ON: High -

004-050 Fuser Fan, LV Fan

and Rear Fan

Rotation High

speed

Rotate the FUSER FAN, LV FAN and

REAR FAN at high speed. (Rotation is Low

at Power ON)

-

005-011 Set Gate Solenoid

Open

Turn Set Gate Open ON (Towards bottom

of Nudger Roll) for 5sec -> Auto OFF

-

005-012 Set Gate Solenoid

Close

Turn Set Gate Close ON (Towards bottom

of Nudger Roll) for 5sec -> Auto OFF

-

005-040 Feed Mot. DADF Feed Motor for 2sec -> Auto OFF -

005-055 Belt Motor Non

CVT Mode (CW)

Rotate the DADF Belt Motor forward. 005-056

005-056 Belt Motor Non

CVT Mode (CCW)

Rotate the DADF Belt Motor backward. 005-055

005-075 Regi Gate Solenoid Push the Regi Gate with the Arm to turn it

ON for 5sec -> Auto OFF

-

Loading...

Loading...