2-78 Phaser 7500 Printer Service Manual

Theory of Operation

Color Shift Correction

The detected Color Registration shift amount is computed and converted into the

following corrective elements. The correction itself is performed by the LPH control.

• Intra engine difference image start occurrence

• Slow scan write position correction (Y fine)

• Slow scan write position correction (Y super fine)

• Slow scan skew/ bow/ LPH linearity correction

• Fast scan write position correction (X rough/X fine)

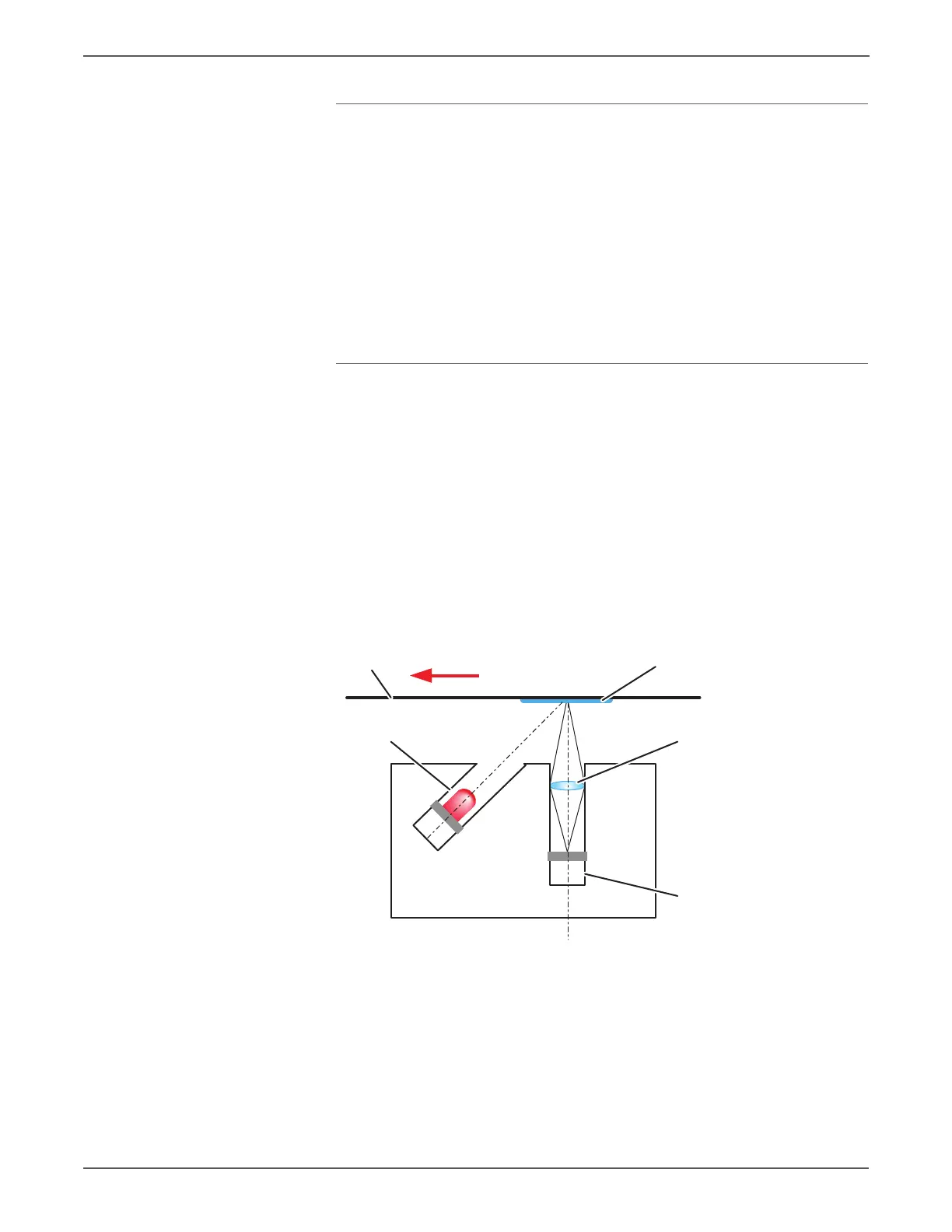

Mark On Belt Sensor

The Mark On Belt (MOB) Sensor detects marks on the belt.

• The MOB Sensor is a reflective sensor that projects the Regi Con (chevron)

patch image that was formed on the opaque belt onto the Detection Unit,

and then outputs a pulse when the center line of the patch is aligned with the

center line of the Detection Unit.

• The above-mentioned Detection Unit consists of only one Photo Diode that is

perpendicular to the belt surface and one LED for diffused light illumination.

• The Sensors (x2) are placed downstream of the last color engine, on the axis

perpendicular to the slow scan direction (in other words, on the axis parallel to

the fast scan direction) in order to detect the relative Color Shift between the

Regi Con patches that were formed by the respective color engines.

s7500-428

Belt

Toner Image

Lens (100%)

Detection PD

Diffusion LED

Loading...

Loading...