5-24 Phaser 7500 Printer Service Manual

Print-Quality Troubleshooting

Do not replace xxxxx without consideration in the troubleshooting procedures

means that other parts of the system as a whole should be considered before

replacing the noted parts. The other parts of the system could include the

Image Processor Board, Memory modules, a customer's network or software

applications being used by the customer. A troubleshooting approach to test

and identify components in isolation of each other should be attempted

before replacing the parts listed under "applicable parts".

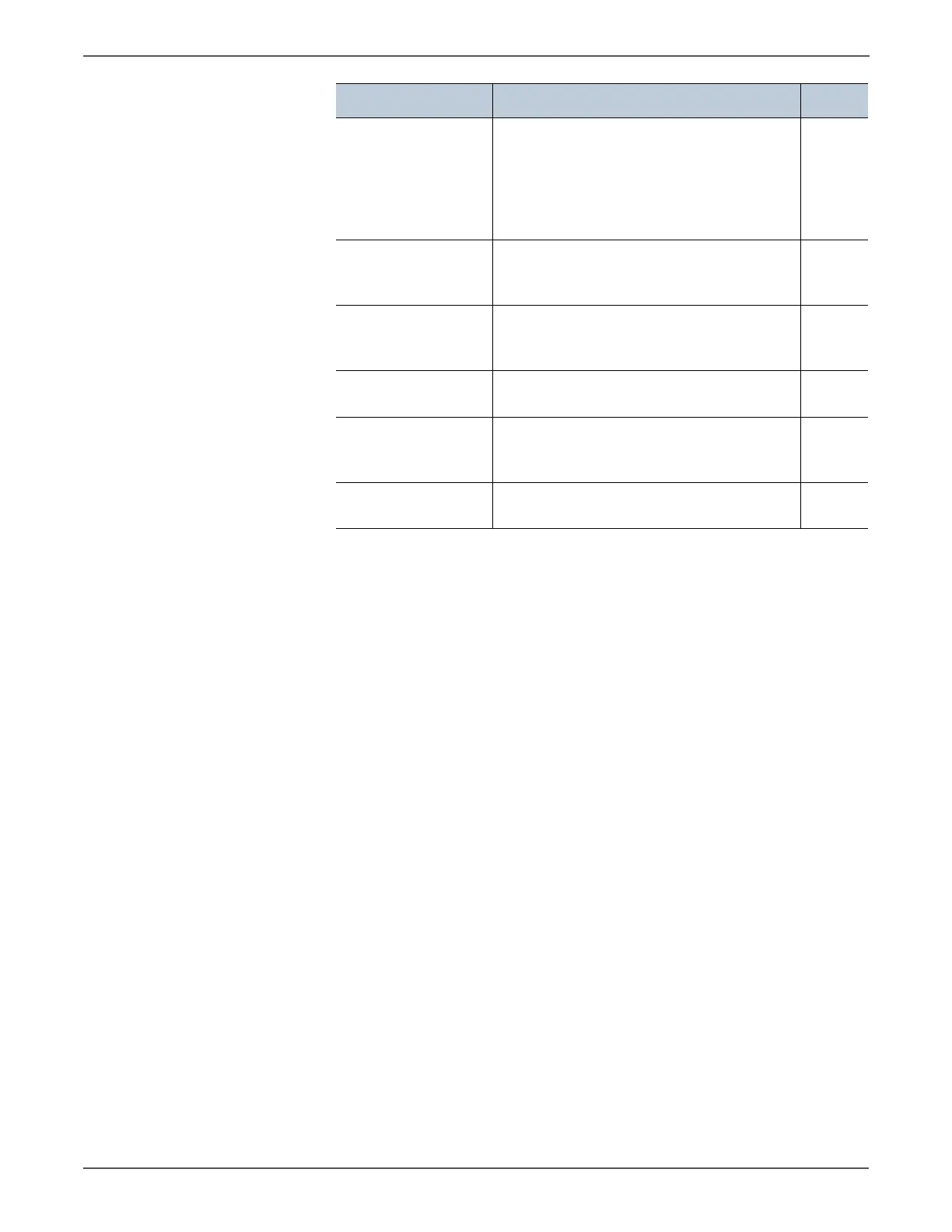

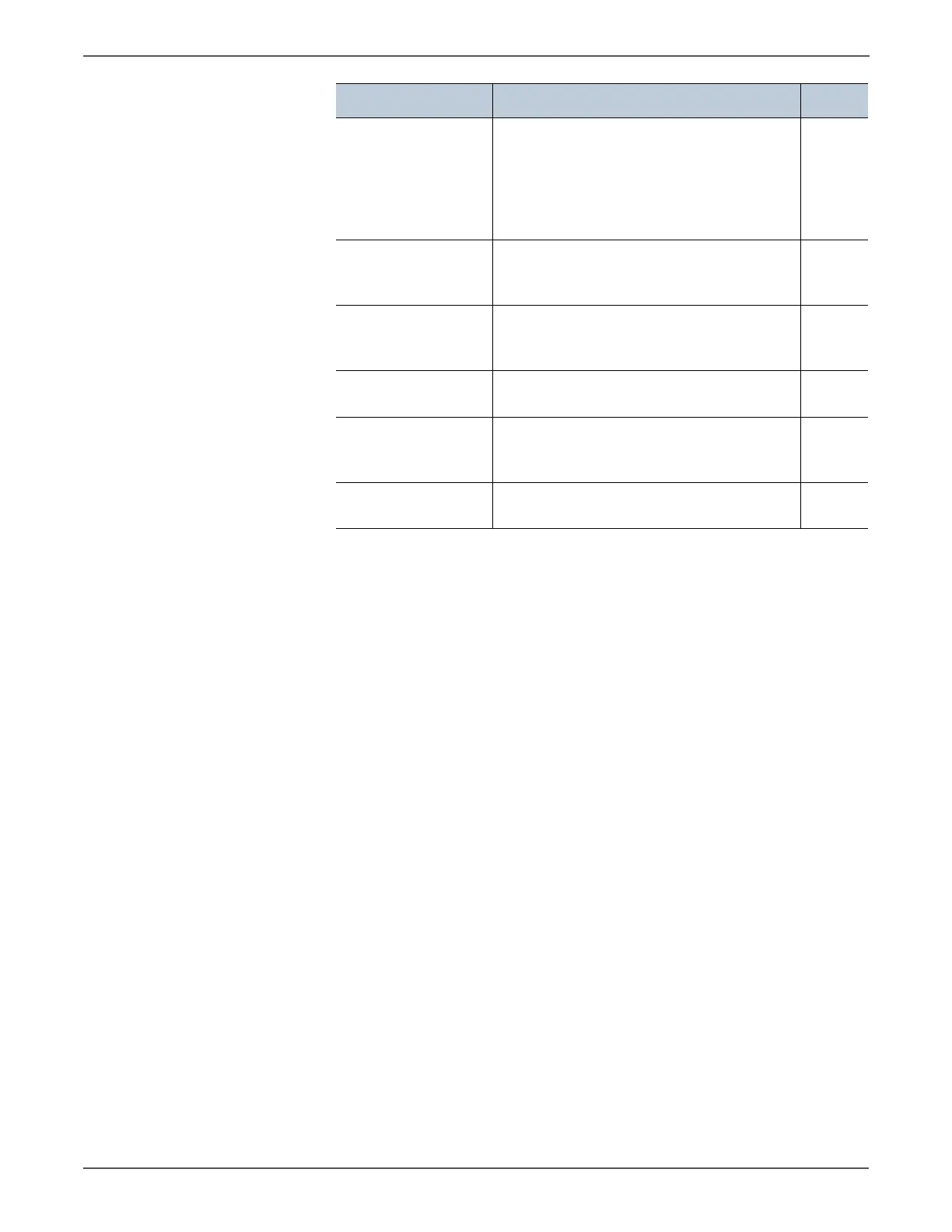

IQ-25 MWS (Side 2)

(Micro White Spots)

When the resistance in the Secondary

Transfer section is high, e.g. in the early

mornings (low humidity environment), the

transfer latitude between multi color and

mono color is narrow and the setting voltage

favors multi color.

5-54

IQ-26 Color Stripes Presence of paper dust in between the

Intermediate Transfer Belt and the CLN Blade

causes poor cleaning.

5-55

IQ-27 Transfer Blank

Areas (Partially Moist

Paper)

Ripples in partially moist paper becomes

wrinkles in the Transfer section, causing blank

areas to appear.

5-56

IQ-28 Nip Marks When using transparencies, slight lines may

appear at the Fuser Heat Roll Pitch.

5-57

IQ-29 Wetting Distorted image may appear at one side or

both sides of the paper tail edge when

printing halftone fill.

5-58

IQ-30 Condensation If condensation occurs in the printer, an

image with water marking may be printed.

5-59

Defect Definition Page

Loading...

Loading...