Phaser 7500 Printer Service Manual 5-23

Print-Quality Troubleshooting

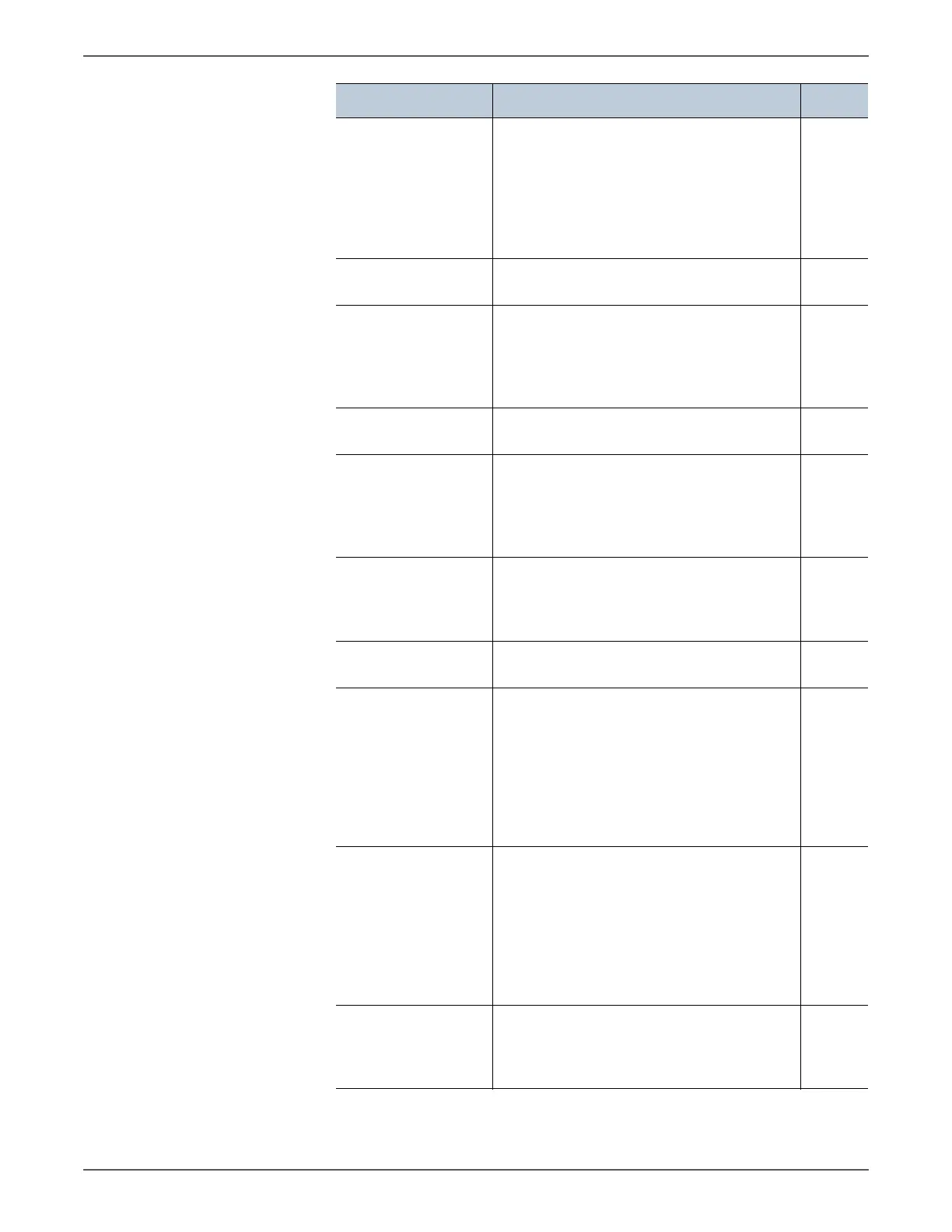

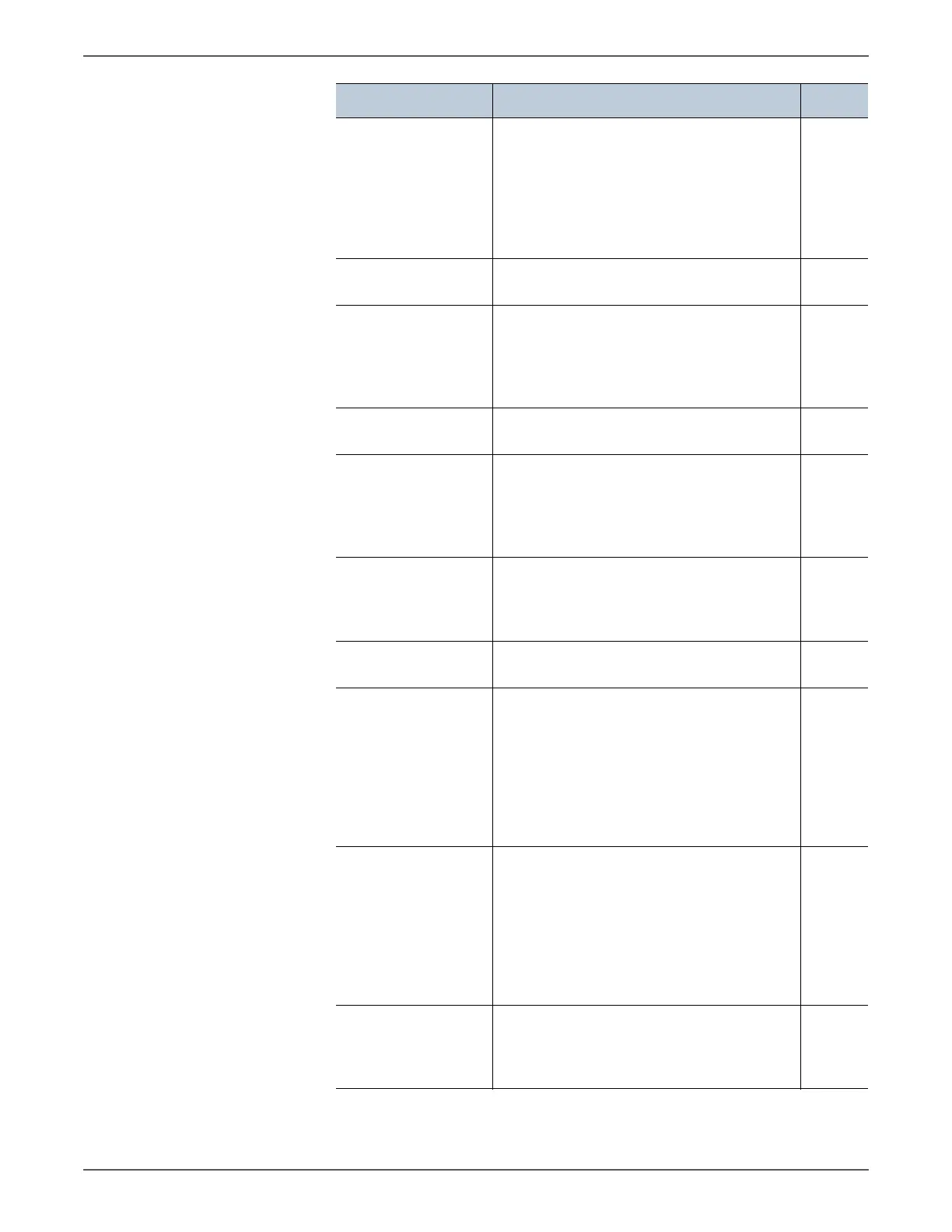

IQ-15 Photoreceptor

Pitch Color Stripes

Vibrations during the Drum CRU

transportation may cause scrapes and friction

in the BCR and the Photoreceptor, resulting in

leftover electrostatic memory on the

Photoreceptor that generates thin white

streaks in the FS direction on the highlight

portion at the Photoreceptor Pitch.

5-42

IQ-16 Background on

Glossy Media

Compared to Plain Paper, background is more

visible on Glossy media.

5-44

IQ-17 Toner Image

Detection Color

Stripes

At Pre Near or Near Empty state, if a

customer had removed the Cartridge and

knocked on it to collect the toner towards the

exit in attempt to use the very last bit of

toner, it may cause color stripe deterioration.

5-45

IQ-18 Toner Droplet

Contamination

A contamination consisting of random

spatters of toner in sizes of a few millimeters.

5-46

IQ-19 Smear on

Heavyweight

When the lead edge of paper reaches the

Secondary Transfer, it immediately increases

the Secondary Transfer section load and

causes the IBT Drive Roll speed to change

(decrease in speed).

5-47

IQ-20 Rough Black On paper that is not flat or has poor hue, the

toner may not have been transferred properly

due to the irregular paper surface, creating a

rough transferred image.

5-49

IQ-21 Moist Paper

Transfer Failure

The resistance is lowered because the paper is

moist.

5-50

IQ-22 Toner

Contamination at

Lead/ Trail Edge

Lead Edge: Paper lead edge contacts the Belt

when it is transported from REGI to Transfer.

Tail Edge: The tail edge of Paper that loops

between the Transfer-Fusing sections, at the

release of the Secondary Transfer NIP, moves

opposite to the feed direction and contacts

the BTR surface, or bounds up and contacts

the Belt.

5-51

IQ-23 Side 2 Transfer

Failure

Paper that has had its Side 1 fused has a

reduced percentage of moisture content,

which increases its electric resistance. Since

the resistance in the Secondary Transfer

section also increases by lower humidity or

over time, the required electrical field may

not be attained, especially in the early

mornings (low humidity environment).

5-52

IQ-24 Trail Edge

Transfer Failure

The paper tail edge, after the Secondary

Transfer NIP has been released, bounded up

due to the fusing stroke effect and re-

transfers to the Intermediate Transfer Belt.

5-53

Defect Definition Page

Loading...

Loading...