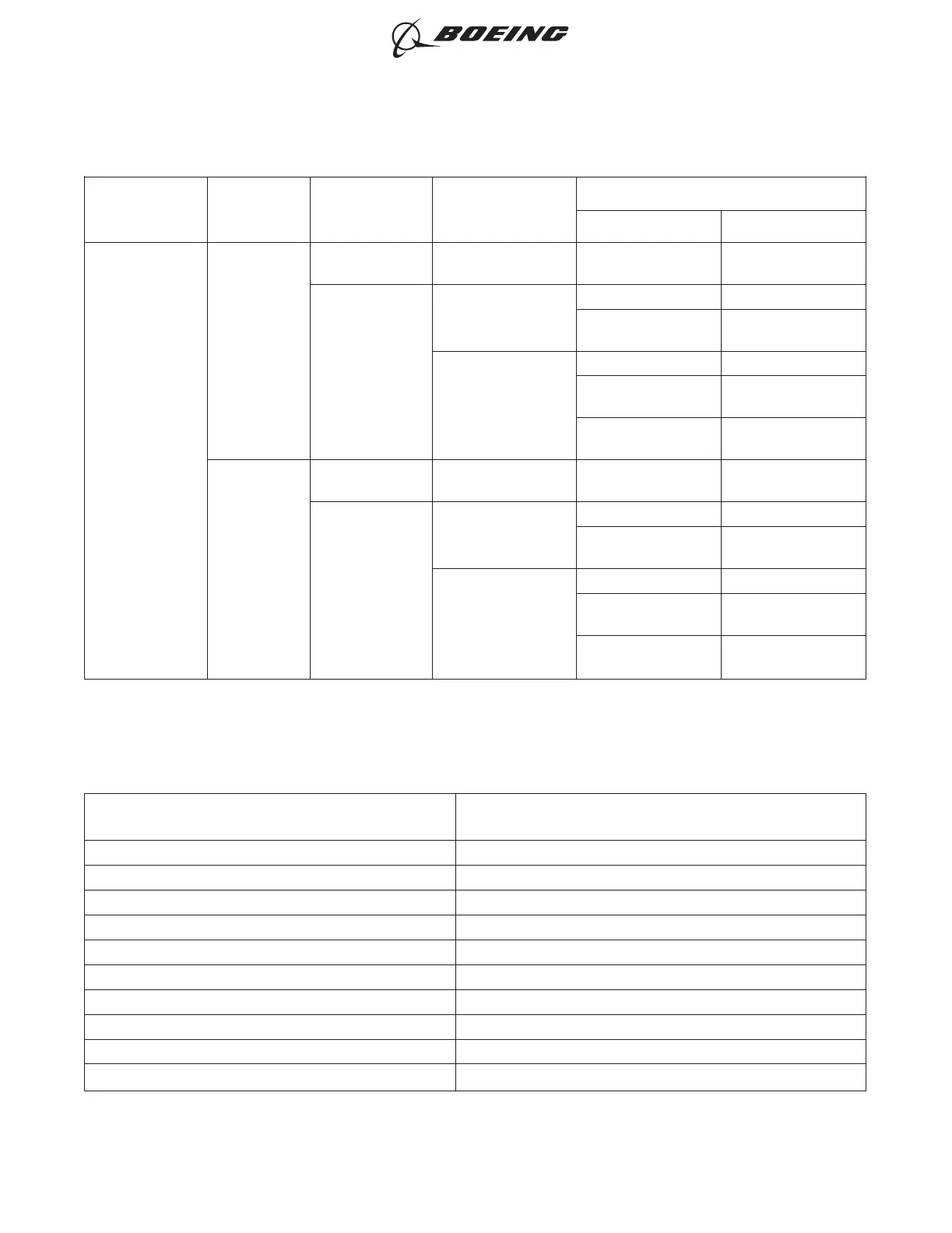

Table 3 SEALED SPLICE CONFIGURATIONS FOR SHIELDED WIRE AND SHIELDED CABLE (Continued)

Maximum

Temperature

Grade

Number of

Shields

Shield

Conductor

Applicable Area

Splice Assembly

Configuration Reference

D

1

Flat No Fuel Vapor

Solder Sleeve Splice

Kit

Paragraph 16.A.

Round

Fuel Vapor

Mechanical Ferrule Paragraph 11.A.

Shield Termination

Rings and Bands

Paragraph 13.A.

No Fuel Vapor

Mechanical Ferrule Paragraph 11.A.

Shield Termination

Rings and Bands

Paragraph 13.A.

Solder Sleeve Splice

Kit

Paragraph 16.A.

2

Flat Inner, Round

Outer

No Fuel Vapor

Solder Sleeve Splice

Kit

Paragraph 16.A.

Round Inner,

Round Outer

Fuel Vapor

Mechanical Ferrule Paragraph 11.A.

Shield Termination

Rings and Bands

Paragraph 13.A.

No Fuel Vapor

Mechanical Ferrule Paragraph 11.A.

Shield Termination

Rings and Bands

Paragraph 13.A.

Solder Sleeve Splice

Kit

Paragraph 16.A.

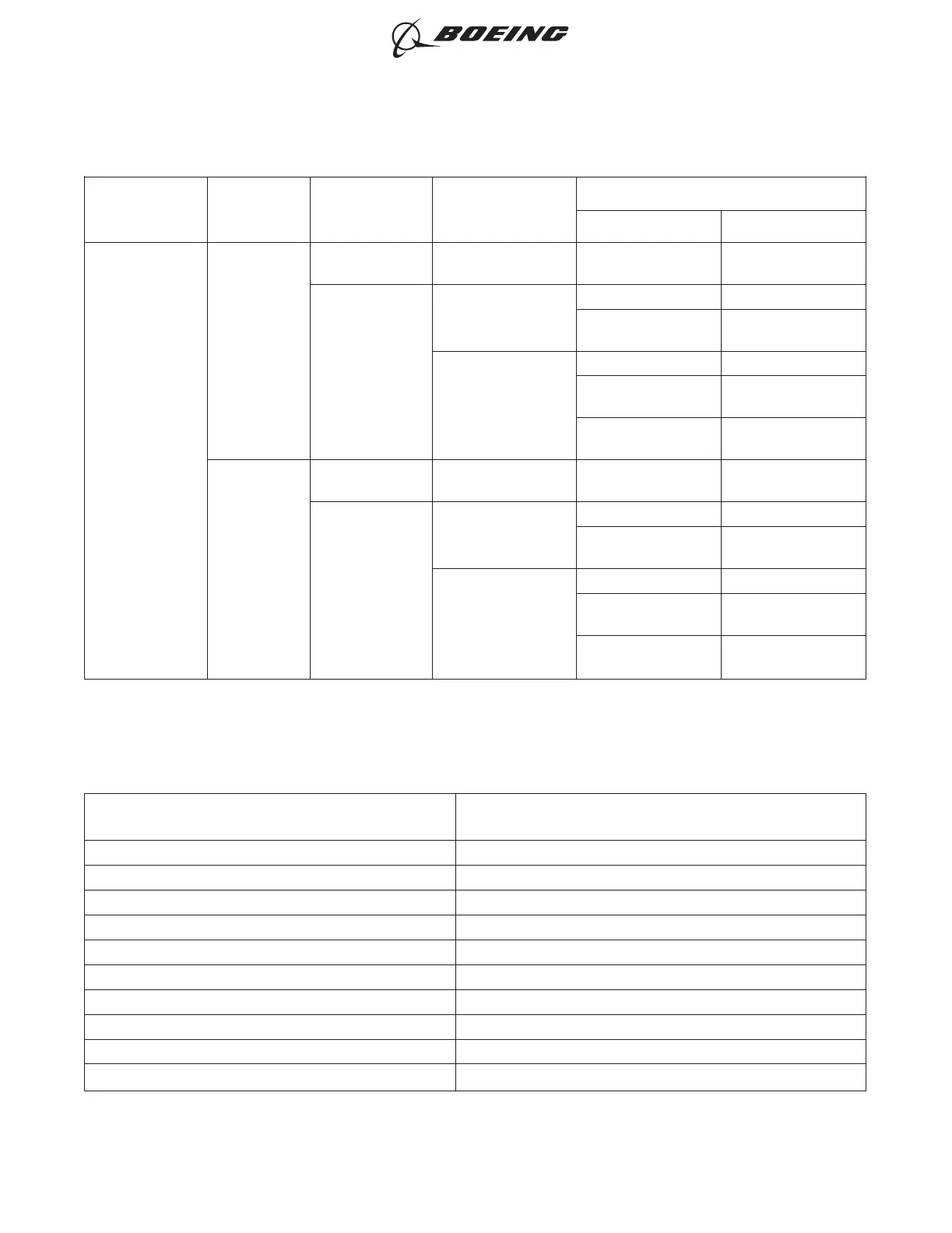

D. Conductor CAU

This paragraph gives the procedure to find the CAU of the conductor or conductors.

Table 4

AWG TO CAU CONVERSION

Wire Size

(AWG)

Circular Area Units

(CAU)

32 0.6

30 1

28 1.6

26 3

24 5

22 8

20 12

18 19

16 24

14 38

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 11

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...