(c) Shrink the sleeve into its position.

(9) For a terminal lug in a high temperature area or in a high vibration area, if a heat gun cannot be

used:

(a) Make a selection of a Grade D TFE tape. Refer to Subject 20-00-11.

(b) Wind a sufficient number of layers of tape around the crimp barrel of the terminal and

around the end of the wire insulation.

Make sure that:

• The tape layers include the crimp barrel of the terminal

• The tape layers make a 50 percent minimum overlap

• The length of the tape layers on the wire insulation is approximately 1.0 inch.

(c) Assemble a wire harness tie near each end of the tape layers to hold the layers in their

position.

J. Assembly of BACT12E 90 Degree Upright Terminal Lugs

Refer to Paragraph 1.F. for the description of the BACT12E upright terminal lugs.

Table 58

CRIMP TOOLS FOR BACT12E UPRIGHT TERMINAL LUGS

Crimp Barrel

Size

Crimp Tool

Basic Unit Head

Die

Primary Secondary Cavity

22 - 18

46447 - - - -

49935 - - - -

16 - 14

49935 - - - -

M8ND - N14HT - -

Y8ND - N14HT - -

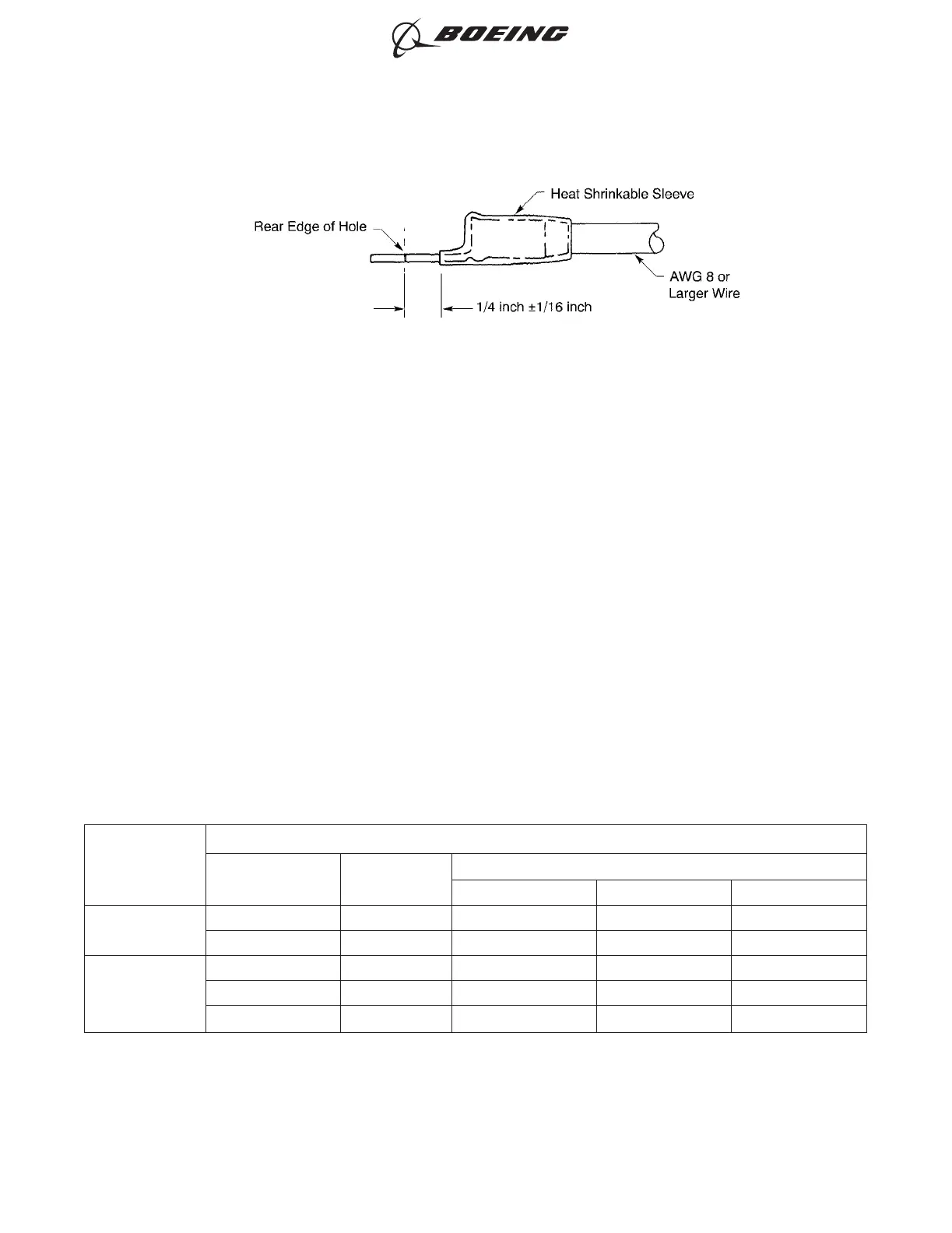

POSITION OF THE SLEEVE FOR SIZE AWG 8 OR LARGER WIRE

Figure 24

ASSEMBLY OF INSULATED AND UNINSULATED TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-11

Page 74

Feb 15/2016D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...