(a) Push the sleeve forward until the forward end of the sleeve is aligned with the rear end of

the tongue of the terminal lug.

(b) Shrink the sleeve into its position. Refer to Subject 20-10-14.

Make sure that the sleeve has a tight fit on the assembly.

J. Extension of the Terminal Lug Assembly Insulation - Standard Configuration

This procedure is applicable when one of these conditions occur:

• The 0.5 inch Type I 20 mil silicone tape is specified for a BACT13K-2, BACT13K-3, or

BACT13K-4 terminal lug

• The 0.5 inch Type I 20 mil silicone tape and the standard extension of the insulation of the

terminal lug assembly are specified for the terminal lug.

Table 24

ASSEMBLY COMPONENTS

Component Type Part Number

Tape Silicone, Type I, 20 mil A-A-59163-1I0020-0.500

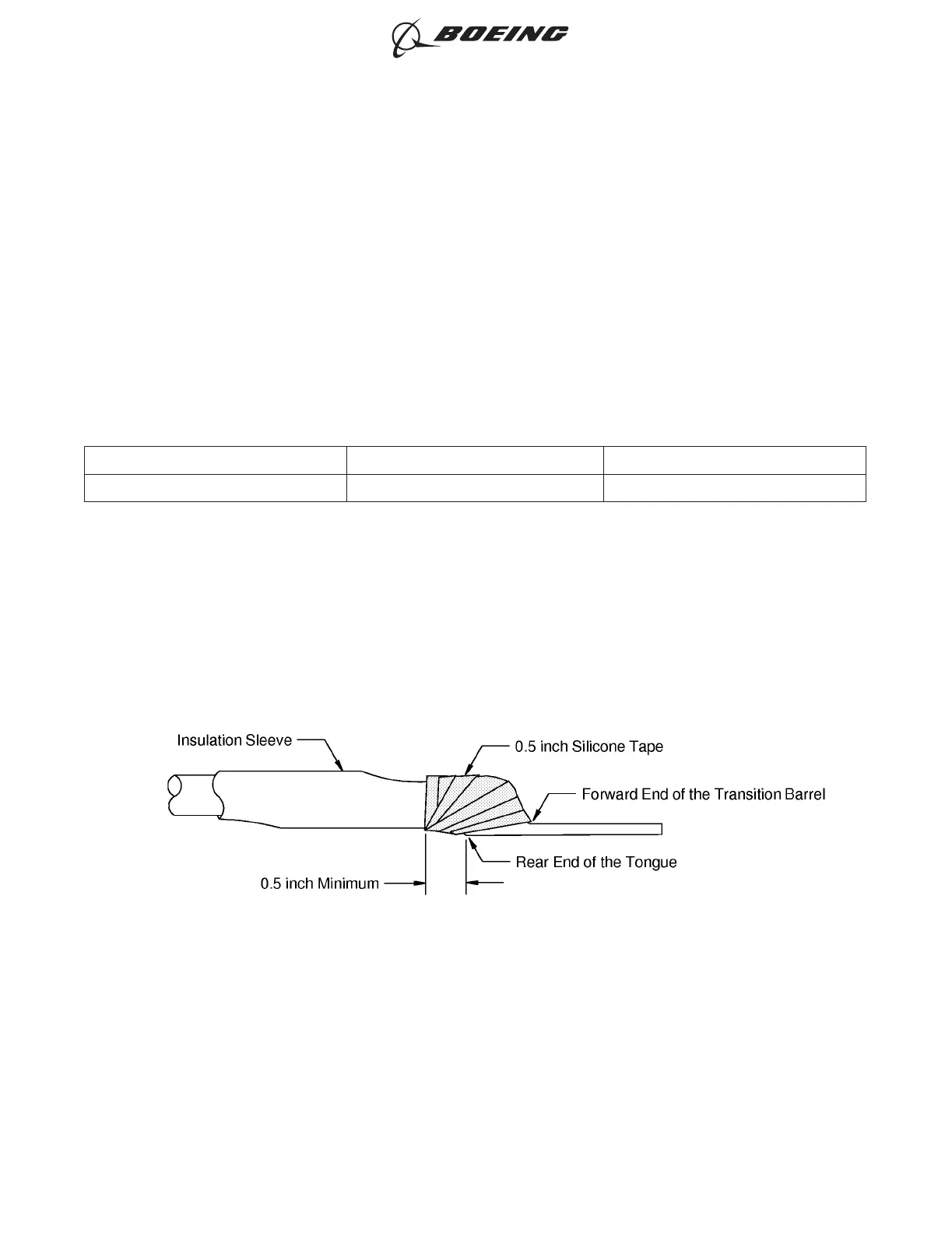

(1) Put two layers of the specified tape on the transition barrel of the terminal lug. Refer to Figure 26,

Make sure that:

• The forward end of each layer is aligned with the forward end of the transition barrel

• The rear end of each layer extends 0.5 inch minimum rearward from the rear end of the

tongue of the terminal lug

• Each layer makes a 50 percent overlap with itself

• The second layer of tape is wound in the opposite direction of the first layer

• The layers of tape do not make an overlap with the bottom surface of the tongue of the

terminal lug.

(2) Examine the extension of the terminal lug insulation.

Make sure that the tape does not make an overlap with the rear end of the bottom of the tongue

of the terminal lug.

POSITION OF THE TAPE ON THE TRANSITION BARREL

Figure 26

ASSEMBLY OF AMP (TYCO) COPALUM, MS25435 AND THOMAS & BETTS ALUMINUM

TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-14

Page 35

Oct 15/2015D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...