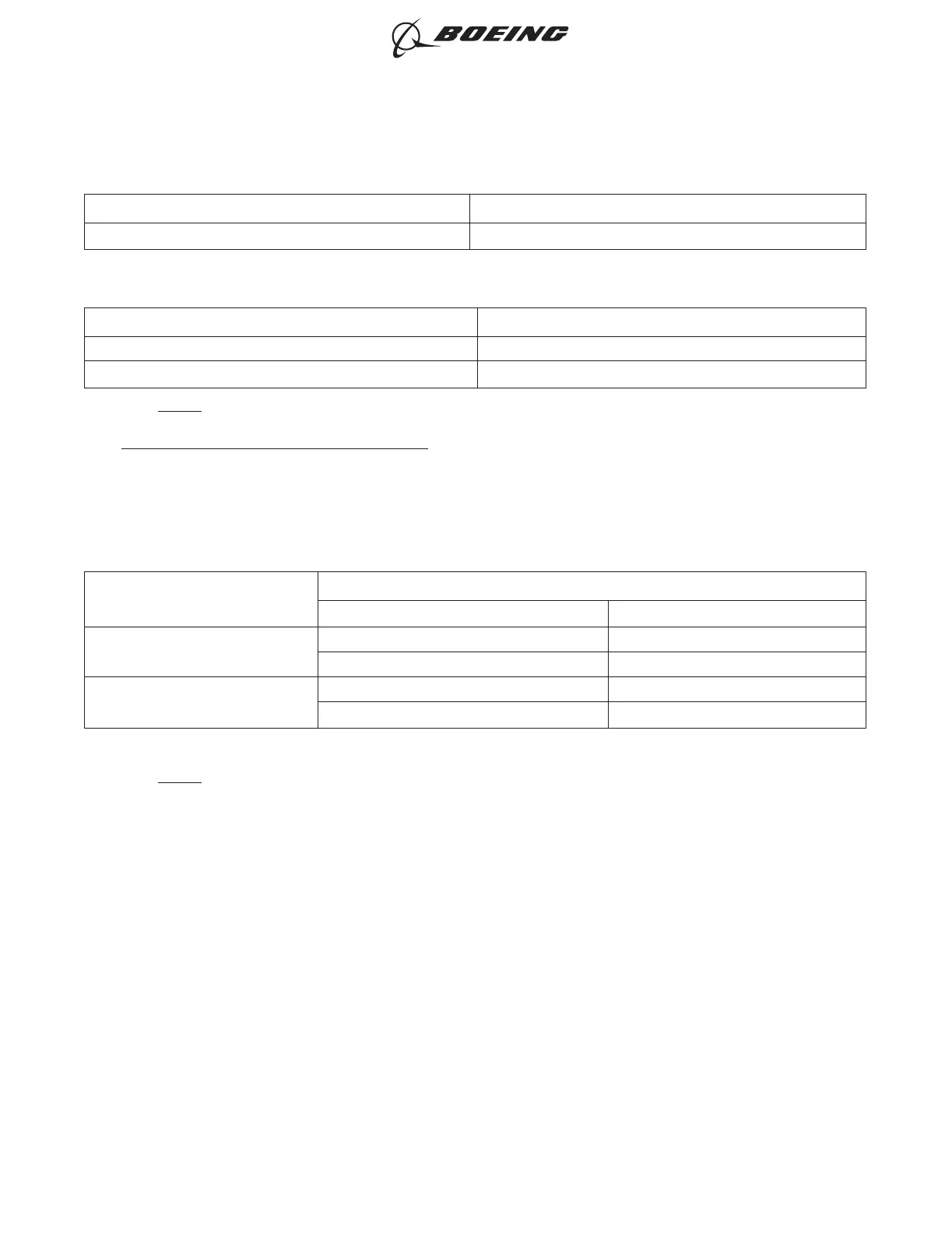

Table 56

APPROVED SUPPLIERS OF BOEING STANDARD SOLDER SLEEVES

Boeing Standard Supplier

BACS13CT Raychem

Table 57

SHIELD SLEEVE MATERIALS

Temperature Grade Boeing Standard

B BAC3108-()

D BAC3106-()

NOTE: For sizes and suppliers of shield sleeve materials, refer to Subject 20-00-11.

5. CLOSED END SPLICE CONFIGURATIONS

A. Splice Assembly Configurations

For the conditions that are applicable for a closed end splice, refer to Paragraph 1.A.

Table 58

CLOSED END SPLICE CONFIGURATIONS

Seal

Splice Assembly

Configuration Procedure

Sealed

Splice Kit Paragraph 5.B.

Parallel Splice and a Sleeve Paragraph 5.C.

Unsealed

Insulated Closed End Splice Paragraph 5.D.

Parallel Splice and a Sleeve Paragraph 5.E.

B. Closed End Splice Configurations - Sealed Closed End Splice - Splice Kit

NOTE: A satisfactory alternative for a sealed closed end splice kit is a sealed closed end splice with a

parallel splice and a sleeve. Refer to Paragraph 5.C.

(1) Make a selection of a sealed closed end splice kit from Table 5.

Make sure that the splice kit has:

• The smallest CAU range that can accept the total CAU of the conductors

• The correct maximum number of wires.

Refer to Paragraph 1.D. for the procedure to calculate the CAU of the conductors.

(2) Find the part number of the parallel splice in the splice kit from Table 6.

(3) Find the crimp barrel size of the splice from Table 6.

(4) Make a selection of a crimp tool from Table 39.

(5) For a sleeve with a 1 hole wire seal, put the sleeve on the wires. Refer to Figure 1.

Make sure to put the end of the sleeve with the wire seal on the wires first.

(6) For a sleeve with a 5 hole wire seal, put the sleeve on the wires. Refer to Figure 2.

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 55

Feb 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...