(8) Put the moving lower die in the ram well.

Make sure that:

• The alignment dot on the front face of the die is on the same side as the ram setscrew.

• The shanks on the moving and the stationary dies are offset from the same surface.

(9) Tighten the ram setscrew.

(10) Leave the yoke open until the piston (ram) returns to the rest position.

(11) Close the yoke and install the latch pin.

(12) Slowly close the dies.

Make sure that the dies are correctly aligned.

(13) Complete the cycle to put the ram in the down position.

Make sure that:

• The dies are installed with the alignment marks on the same side of the tool head

• The dies are attached correctly to the tool head

• The latch pin is fully installed in the tool head.

NOTE: The alignment marks can be marked with an ink marker to make the assembly easier.

NOTE: For confined areas, the nest die can be put in the ram and the indenter die can be put in

the yoke.

N. Insulation of the Terminal Lug Assembly

Table 26

NECESSARY MATERIALS

Material Description Part Number Supplier

Tape, Insulation 1.0 inch wide

Scotch 70 3M

A-A-59163 QPL

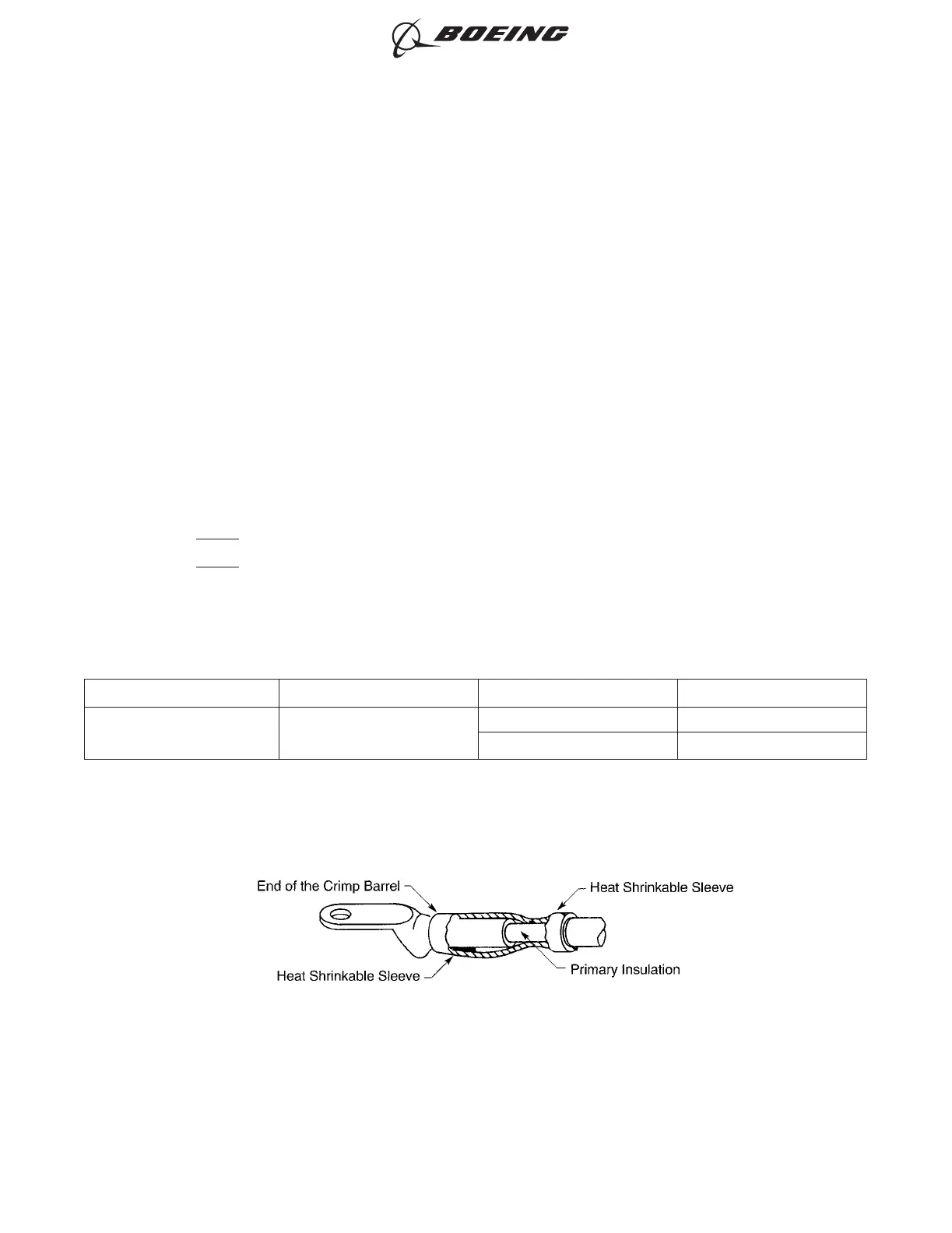

(1) If the insulation is a heat shrinkable sleeve:

(a) Push the sleeve over the end of the insulation so that the sleeve makes an overlap with the

crimp barrel of the terminal. Refer to Figure 35.

POSITION OF THE HEAT SHRINKABLE SLEEVE ON THE TERMINAL AND THE WIRE

Figure 35

ASSEMBLY OF AMP (TYCO) COPALUM, MS25435 AND THOMAS & BETTS ALUMINUM

TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-14

Page 44

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...