(b) Shrink the sleeve in position. Refer to Subject 20-10-14.

(2) If the insulation is a cold shrink sleeve:

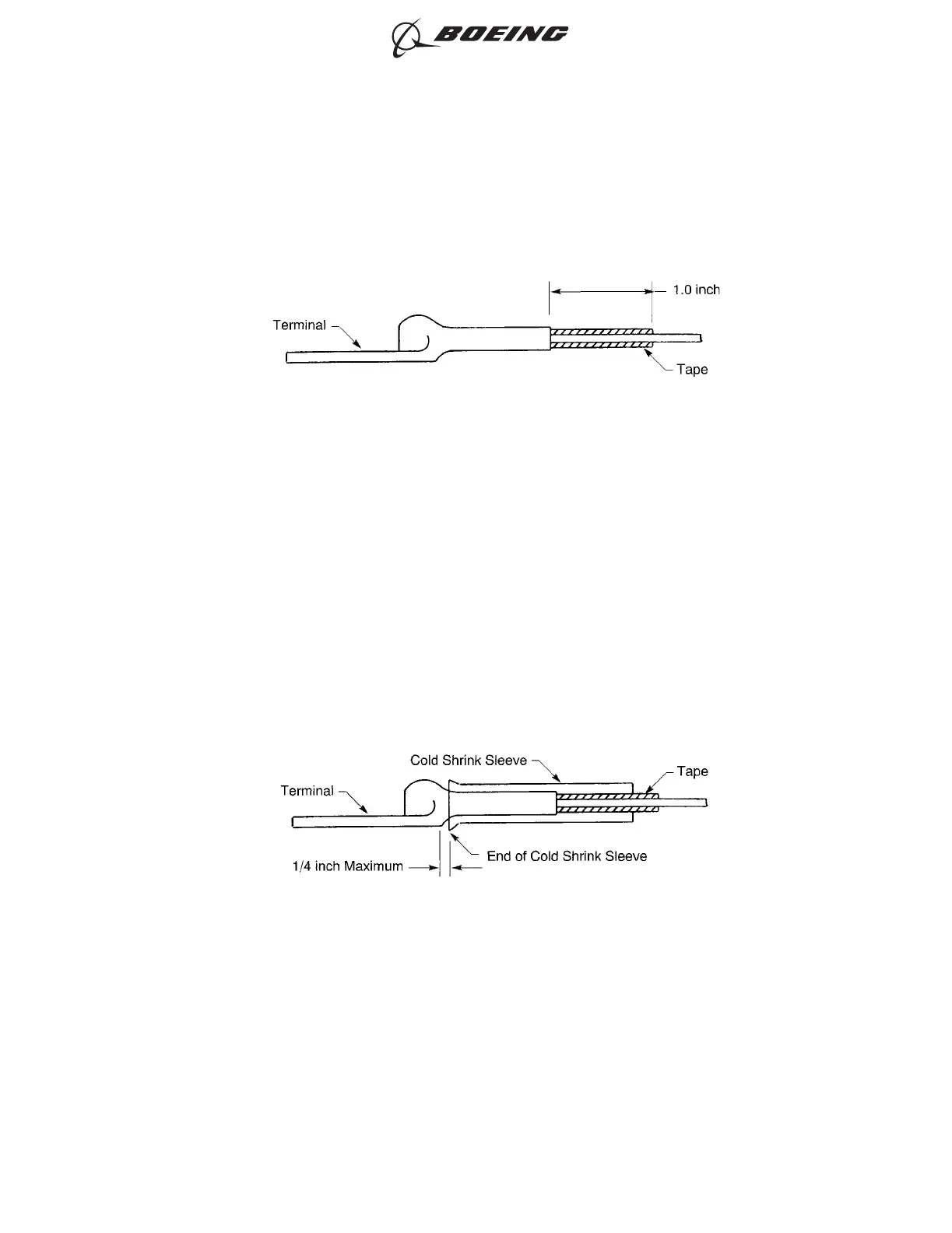

(a) For AWG 6 wire, make a selection of an insulating tape from Table 26.

(b) Put 3 layers of insulating tape on the wire so that:

• One end of the tape is aligned with the rear end of the crimp barrel

• The other end of the tape is 1 inch from the rear end of the crimp barrel.

Refer to Figure 36.

Make sure that:

• The tape is not tightened more than necessary

• The contour of the wire is visible under the tape.

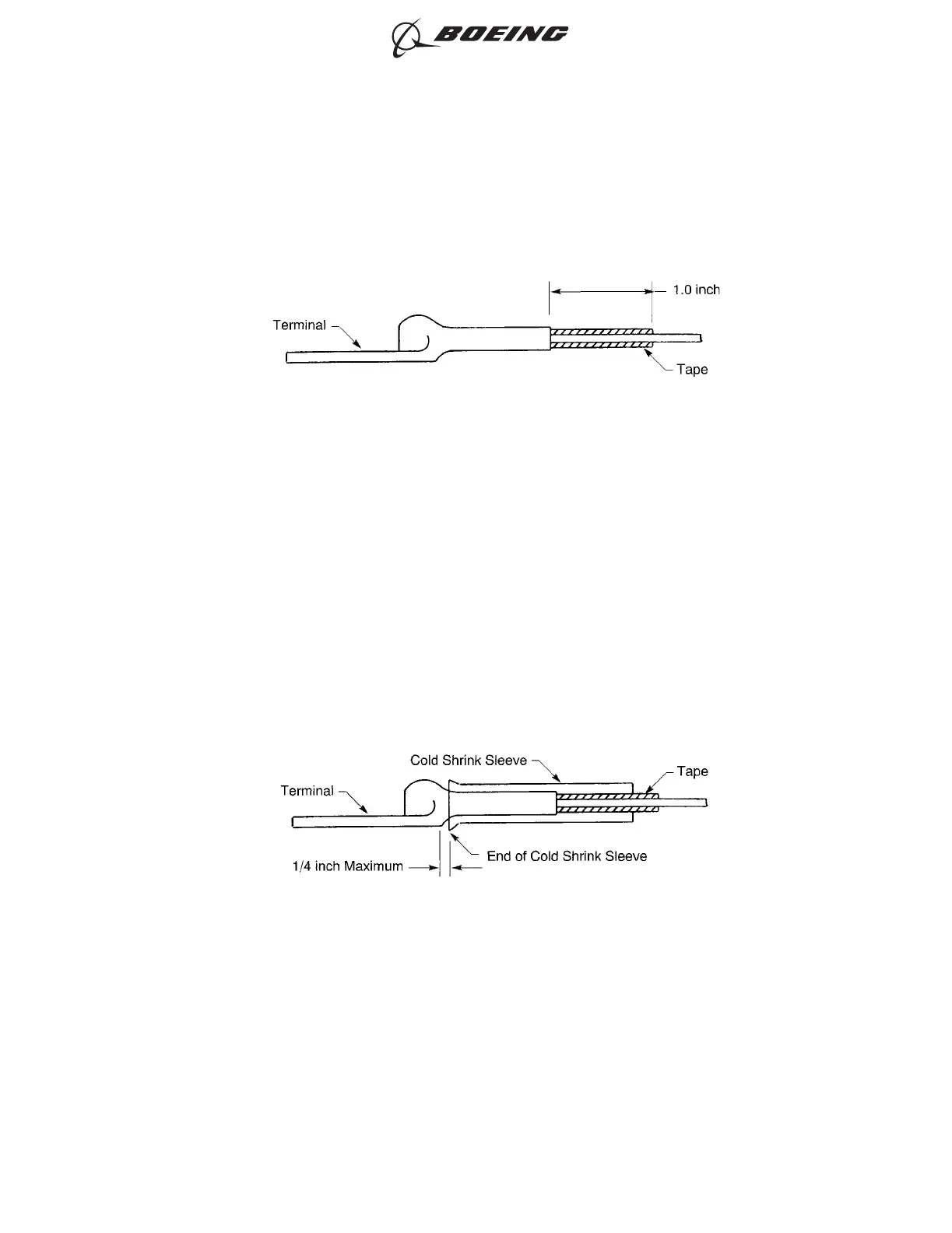

(c) Push the cold shrink sleeve toward the terminal until the end of the sleeve is aligned with

the end of the crimp barrel. Refer to Figure 37 and Figure 38.

POSITION OF THE LAYERS OF TAPE ON THE WIRE

Figure 36

POSITION OF THE COLD SHRINK SLEEVE AND THE TAPE ON THE TERMINAL ASSEMBLY

Figure 37

ASSEMBLY OF AMP (TYCO) COPALUM, MS25435 AND THOMAS & BETTS ALUMINUM

TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-14

Page 45

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...