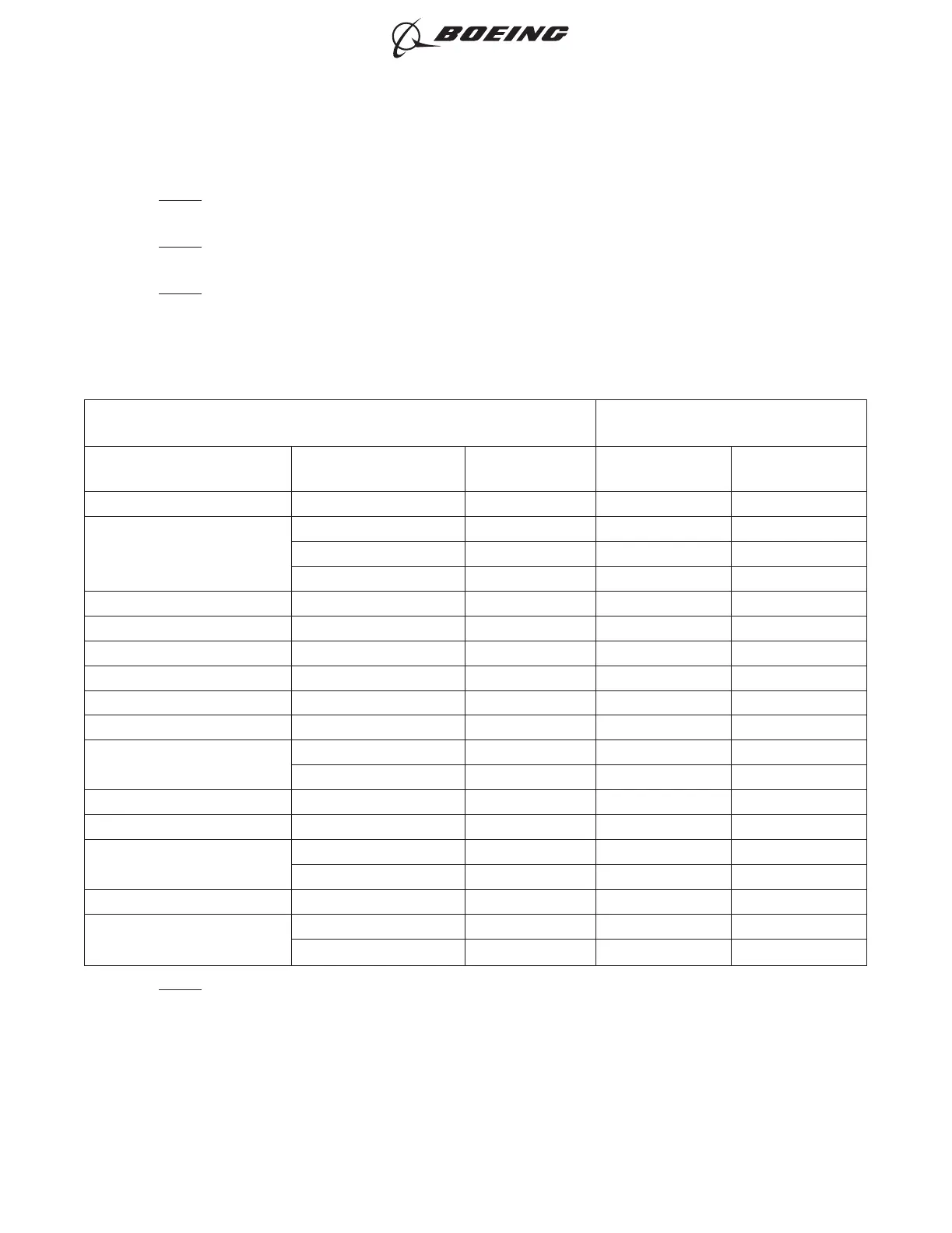

H. Installation Torque for Circuit Breaker, Relay, Contactor, and Time Delay Module Terminals

NOTE: If a terminal torque value is specified on the circuit breaker, relay, contactor, or time delay

module, use that torque value.

NOTE: If the relay, contactor, or time delay module part number is not shown in Table 12, use the

torque values specified in Table 13.

NOTE: For the MS27751-( ) relays, use the torque values specified on the relay.

If the torque values are not specified on the MS27751-( )relay, use the values in Table 12

specified for the MS27751-( ) relay.

Table 11

TERMINAL INSTALLATION TORQUE FOR CIRCUIT BREAKERS

Circuit Breaker

Terminal Installation Torque

(inch-pounds)

Part Number

Current Rating

(Amps)

Stud Size Minimum Maximum

170-006-140 140 1/4-28 40 45

10-60806-()

5 THROUGH 35 8-32 14 15

35 THROUGH 50 8-32 25 27

60 THROUGH 100 1/4-28 40 45

BACC18U( ) ALL 8-32 14 15

BACC18W() ALL 8-32 14 15

BACC18Z() ALL 8-32 14 15

BACC18AC() ALL 8-32 14 15

BACC18AD() ALL 8-32 14 15

BACC18AE() ALL 8-32 14 15

BACC18AF()

5 THROUGH 25 10-32 18 20

35 THROUGH 100 1/4-28 40 45

BACC18R() 5 THROUGH 50 8-32 14 15

BACC18R() (Type C) 60 THROUGH 100 1/4-28 40 45

BACC18X()

5 THROUGH 50 8-32 14 15

60 THROUGH 100 1/4-28 40 45

MS22073() ALL 8-32 14 15

SM600BA( )A1

5 THROUGH 25 10-32 18 20

35 THROUGH 100 1/4-28 40 45

NOTE: Do not use a power tool to torque the screws on 10-60806-( ) or BACC18X( ) circuit breakers

up to and including a rating of 50 Amps.

ELECTRICAL CONNECTION OF EQUIPMENT AND INSTALLATION OF TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-00

Page 26

Feb 15/2019D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...