• Table 56 for a BACT12AR terminal lug

• Table 53 for a BACT12AC terminal lug.

(6) Put the conductor of the wire in the crimp barrel of the terminal lug.

Make sure that:

• All of the strands of the conductor are in the crimp barrel

• The end of the conductor extends farther than the end of the crimp barrel

• The end of the wire insulation is in the insulation grip of the terminal lug

• If a sleeve or tape is on the wire, the end the sleeve or tape is in the insulation grip of the

terminal lug

• If a sleeve or tape is on the wire, the sleeve or tape does not go into the crimp barrel of the

terminal lug

• The clearance from the end of the conductor is sufficent for the installation of the washer

and the nut.

(7) Crimp the terminal lug.

Make sure that:

• All of the strands of the conductor are in the crimp barrel

• The end of the conductor extends farther than the end of the crimp barrel

• The end of the wire insulation is in the insulation grip of the terminal lug

• The crimp tool is adjusted to give the correct insulation support. Refer to Paragraph 2.B.

• If a sleeve or tape is on the wire, the end the sleeve or tape is in the insulation grip of the

terminal lug

• If a sleeve or tape is on the wire, the sleeve or tape does not go into the crimp barrel of the

terminal lug

• The clearance from the end of the conductor is sufficent for the installation of the washer

and the nut.

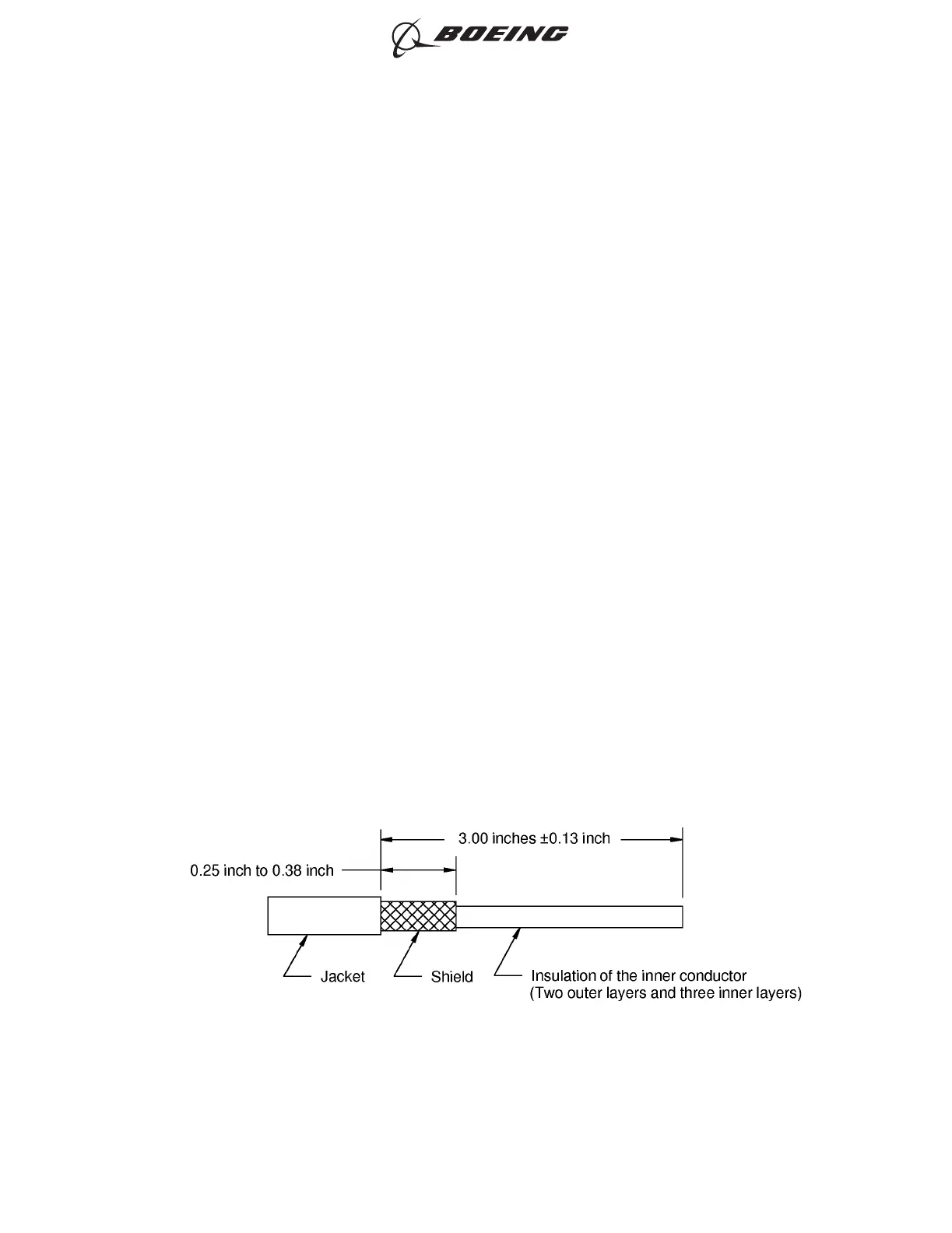

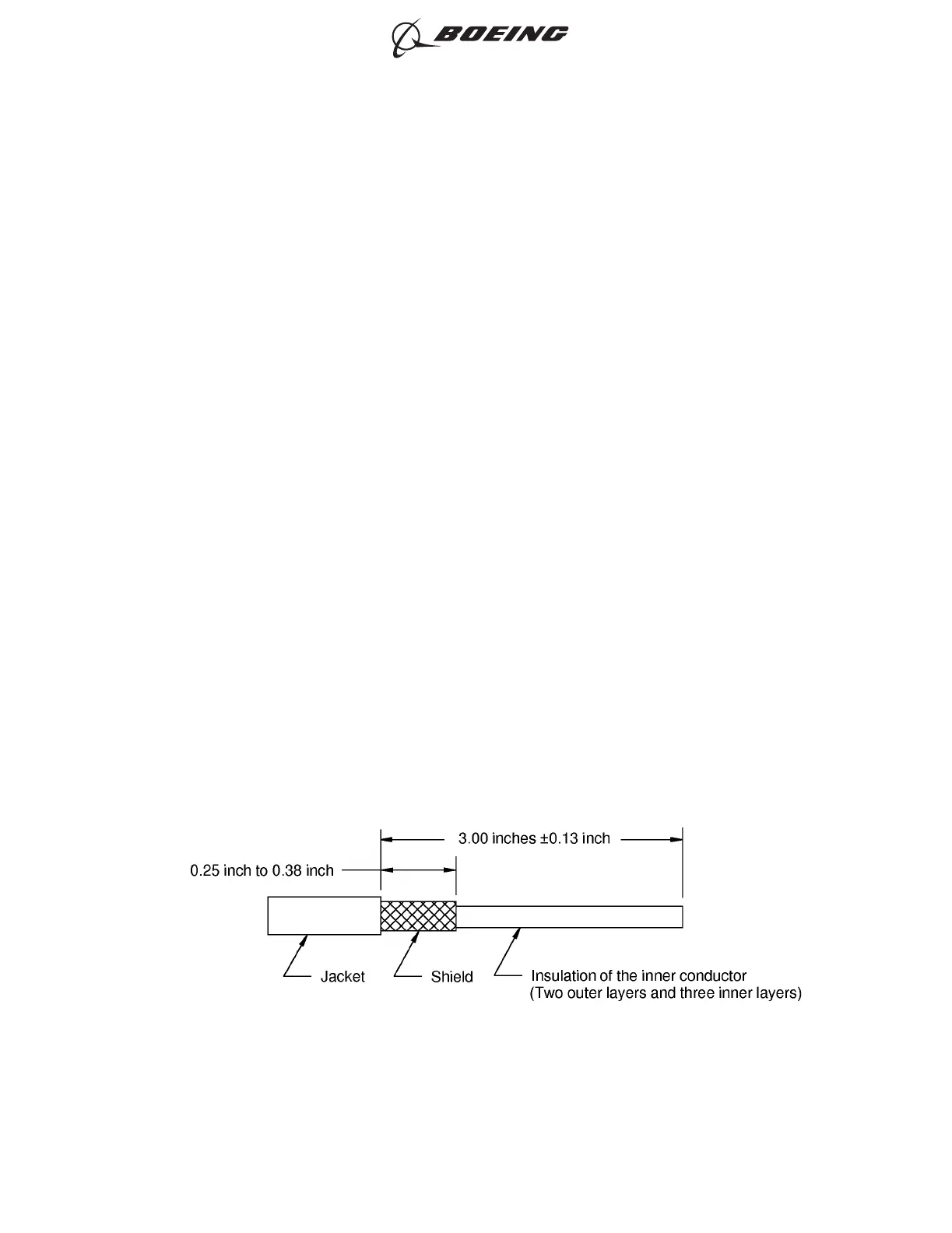

G. Preparation of Cable Type 9U (BMS 13-67 Type 2, Class 1) for Terminals 32189(), 323749 and

323750

Refer to Figure 18:

(1) Remove 3.00 inches ±0.13 inch of the jacket from the end of the wire.

CABLE PREPARATION

Figure 18

ASSEMBLY OF INSULATED AND UNINSULATED TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-11

Page 67

Feb 15/2016D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...