E. Asembly of the Shield Splice

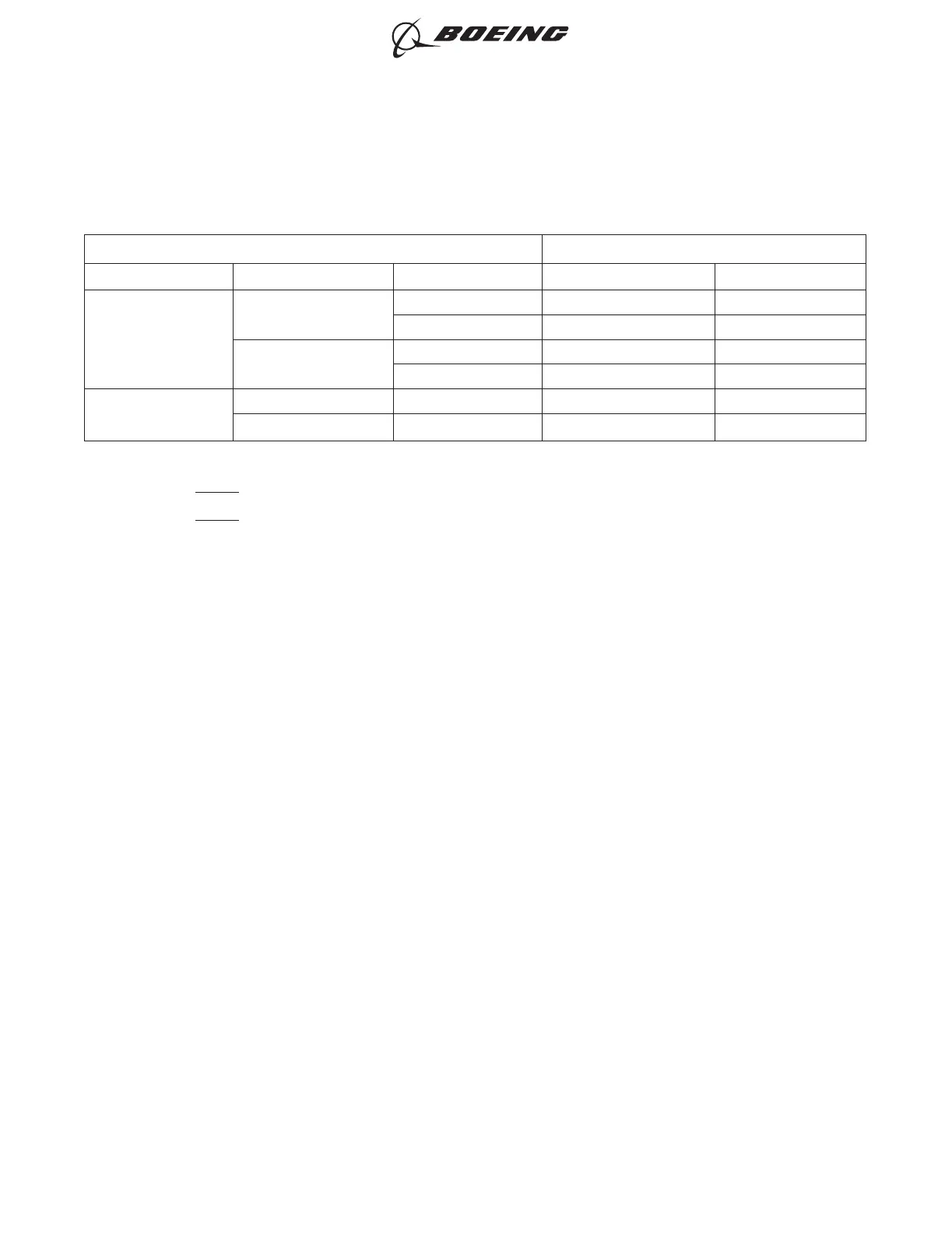

Table 9

SOLDER SHIELD SPLICE SLEEVE INSTALLATION TOOLS

Tool Reflector

Description Part Number Supplier Part Number Supplier

Hot Air Gun

HL1802E

Steinel 07061 Steinel

Steinel 07461 Steinel

HL1910E

Steinel 07061 Steinel

Steinel 07461 Steinel

I/R Heat Tool

IR-550 Tyco RG-2 Tyco

IR-1759 Tyco AE-424 Tyco

(1) Make a selection of a heat tool from Table 9

NOTE: A different tool is a satisfactory alternative if it can give equivalent results.

NOTE: If it is not possible, a hot air gun without a reflector is permitted.

(2) If one build-up sleeve is on the wiring:

(a) Push the sleeve forward until the forward end of the sleeve is 0.2 inch ±0.03 inch from the

rear edge of the shield.

(b) Shrink the sleeve into its position. Refer to Subject 20-10-14.

Make sure that the sleeve has a tight fit on the wiring.

(3) If two build-up sleeves are on the wiring:

(a) Push the smaller sleeve forward until the forward end of the sleeve is 0.2 inch ±0.03 inch

from the rear edge of the shield.

(b) Shrink the sleeve into its position. Refer to Subject 20-10-14.

Make sure that the sleeve has a tight fit on the wiring.

(c) Push the other sleeve forward until the forward end of the sleeve is 0.2 inch ±0.03 inch from

the rear edge of the shield.

(d) Shrink the sleeve into its position. Refer to Subject 20-10-14.

Make sure that the sleeve has a tight fit on the first sleeve.

(4) Align the center of the solder shield splice sleeve with the approximate center of the cable splice

assembly on the two cables.

(5) Apply heat to the center of the solder shield splice sleeve until the solder starts to melt and the

sleeve starts to shrink tight on the cables.

(6) Slowly move the heat toward one end of the shield to make the sleeve shrink as the heat is

applied.

(7) Apply more heat to the final half inch of the shield for 5 to 10 seconds.

Make sure that sufficient heat is applied to make a good solder joint.

ASSEMBLY OF BACS52R SHIELDED SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-19

Page 33

Oct 15/2015D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...