CAUTION

IF THE O.D. OF THE WIRE IS LESS THAN THE MINIMUM O.D SPECIFIED,

THE O.D. OF THE INSULATION MUST BE INCREASED TO MAKE A SEAL

IN THE SPLICE.

(3) Make a selection of a heat shrinkable sleeve from Table 7.

NOTE: A satisfactory alternative is layers of self-bonding silicone tape that are applied after the

splice is assembled. Refer to Paragraph 4.I.

(4) Put a 1.5 inch length of 1/4 inch diameter sleeve on one wire.

(5) Put a 1.5 inch length of 1/4 inch diameter sleeve on the other wire.

(6) Put the 5 inch length of 1/2 inch diameter sleeve on a wire.

(7) Remove the necessary length of the insulation from the end of each wire.

Refer to:

• Table 9

• Subject 20-00-15 for the insulation removal procedures.

Make sure that the end of each wire has not been crimped before.

(8) If the O.D. of the wire insulation is less than the minimum O.D. specified in Table 1 or Table 2,

increase the O.D. of the wire.

For the procedure to increase the O.D. of the wire insulation with:

• Layers of tape, refer to Paragraph 4.F.

• Heat shrinkable sleeves, refer to Paragraph 4.G.

C. Wire Preparation - AMP 277156-1 Splices with AWG 8 Wire

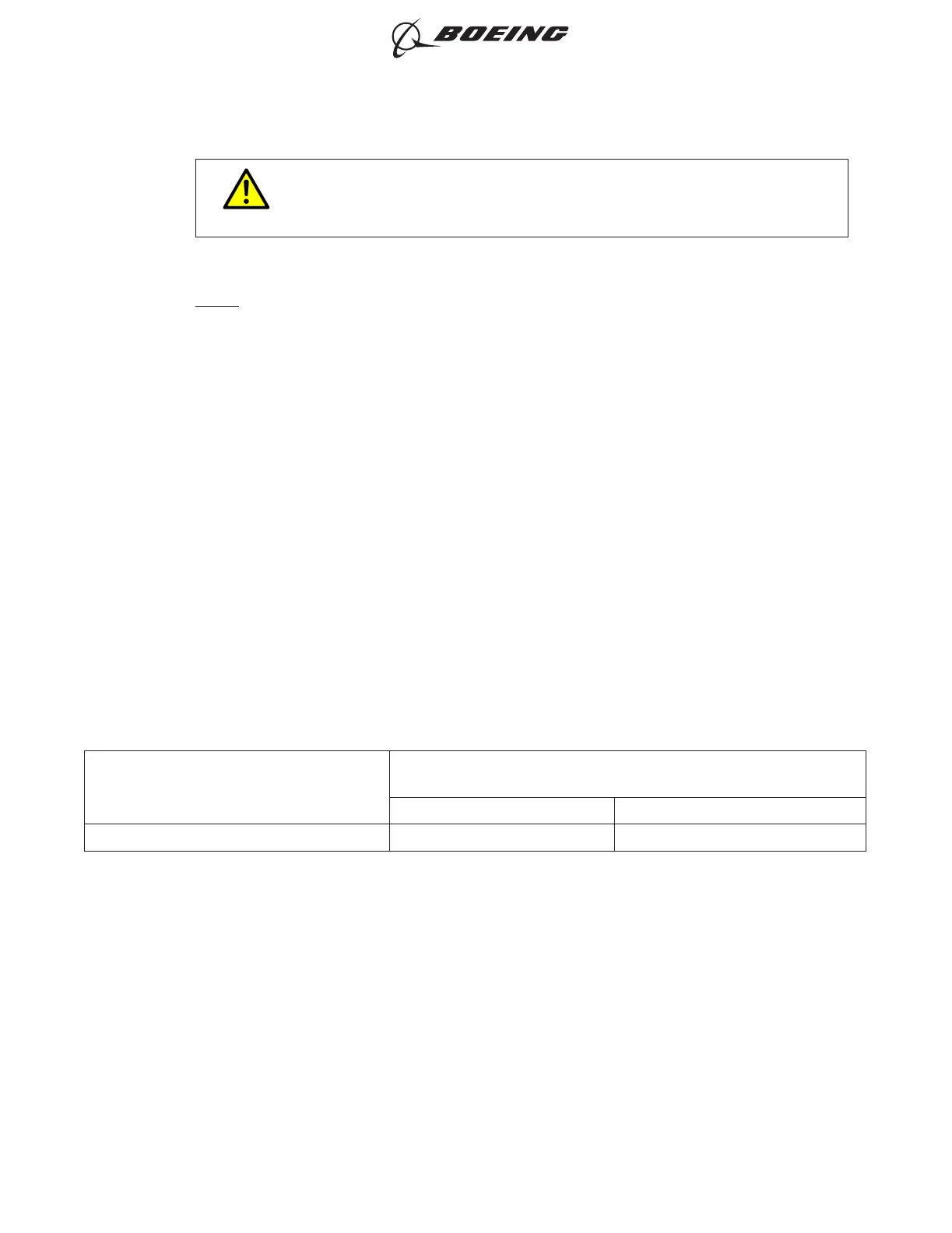

Table 10

INSULATION REMOVAL LENGTH

Splice

Removal Length

(inch)

Target Tolerance

277156-1 0.44 ±0.03

(1) Measure the O.D. of the wire insulation on each wire that must have a splice.

(2) Make a selection of one of these splices:

• A standard butt splice; refer to Paragraph 2.A.

• A transitional butt splice; refer to Paragraph 2.B..

ASSEMBLY AND REPAIR OF THE AMP AND BACS52N COPALUM SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-13

Page 11

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...