(5) Remove any sharp edges from the terminal.

NOTE: The condition where the base metal of the terminal can be seen:

• Is not recommended

• Is permitted.

(6) Install the insulation sleeve. Refer to Paragraph 2.N..

H. Assembly of BACT12AW, BACT12AY, BACT13K, BACT13L, and BACT13T Copalum Terminals

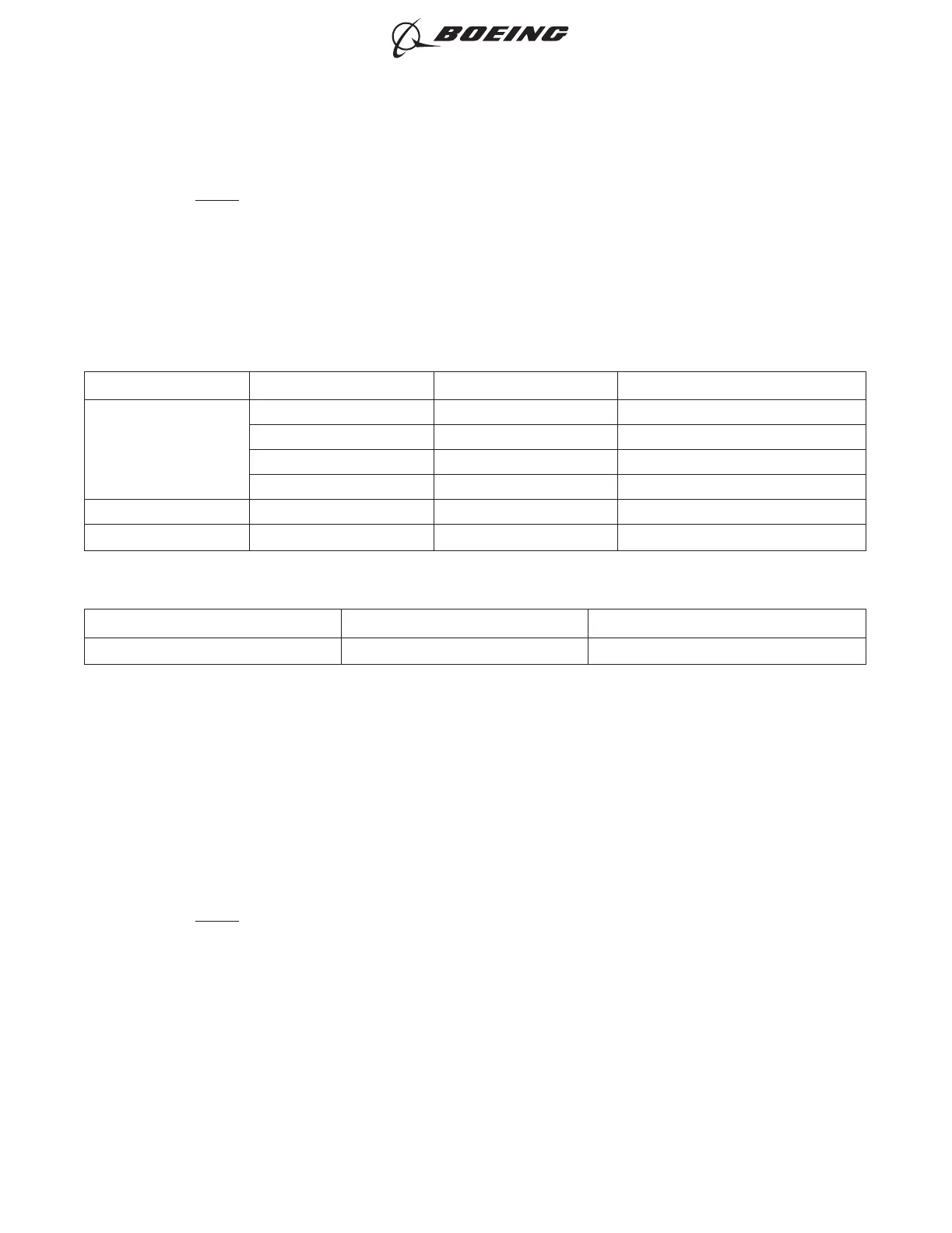

Table 21

NECESSARY MATERIALS

Material Specification Description Supplier

Release Agent

MS-122DF - Miller Stephenson Chemical

MS-122N/C02 - Miller Stephenson Chemical

MS-122V - Miller Stephenson Chemical

MS-122XD - Miller Stephenson Chemical

Solvent TT-I-735 Isopropyl Alcohol An available source

Wiper BMS15-5 - QPL

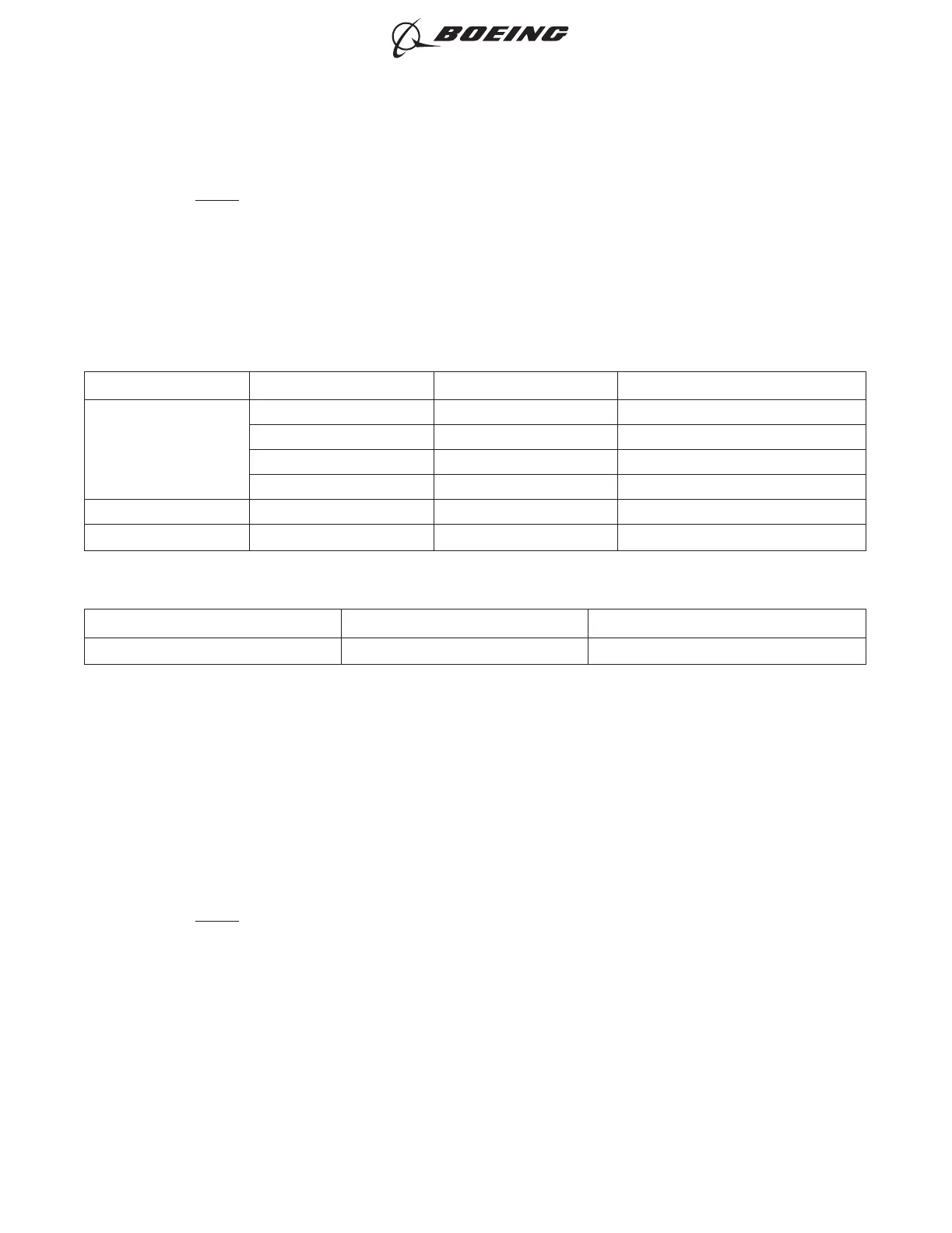

Table 22

NECESSARY TOOL

Tool Type Supplier

File Fine Tooth An available source

(1) Prepare the hydraulic crimp tool for operation.

Refer to:

• Paragraph 2.L.

• Paragraph 2.M..

(2) Make a selection of a release agent from Table 21.

(3) Examine the crimp tool dies.

Make sure that:

• The smooth metal surfaces do not have damage

• The nest and indenter dies have not collected a quantity of the release agent or plating.

NOTE: The incorrect formation of the certification mark can occur if the indenter dies are not

clean.

(4) If the nest or indenter dies have collected a quantity of the release agent or plating:

(a) Make a selection of solvent from Table 21.

(b) Brush the dies with a soft bristle brush.

(c) Wipe the dies clean with a wiper and solvent.

(5) Apply a small amount of release agent to the die set. Refer to Table 21.

ASSEMBLY OF AMP (TYCO) COPALUM, MS25435 AND THOMAS & BETTS ALUMINUM

TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-14

Page 27

Oct 15/2015D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...