(6) Put the end of the wire in the crimp barrel of the terminal lug.

Make sure that:

• The tongue of a BACT13T terminal lug does not have a bend that is more than 0.15 inch

from the longitudinal axis of the bottom surface of the tongue

• All of the strands of the conductor are in the crimp barrel.

CAUTION

IF THE TONGUE OF A BACT13T TERMINAL LUG HAS A BEND THAT IS

MORE THAN 0.15 INCH FROM THE LONGITUDINAL AXIS OF THE

BOTTOM SURFACE OF THE TONGUE, THE TERMINAL LUG IS DAMAGED

AND MUST NOT BE USED.

CAUTION

IF THE TONGUE OF A BACT13T TERMINAL LUG HAS A BEND THAT IS

MORE THAN 0.15 INCH FROM THE LONGITUDINAL AXIS OF THE

BOTTOM SURFACE OF THE TONGUE, DO NOT TRY TO MAKE THE

TONGUE STRAIGHT. THE TERMINAL LUG IS DAMAGED AND MUST NOT

BE USED.

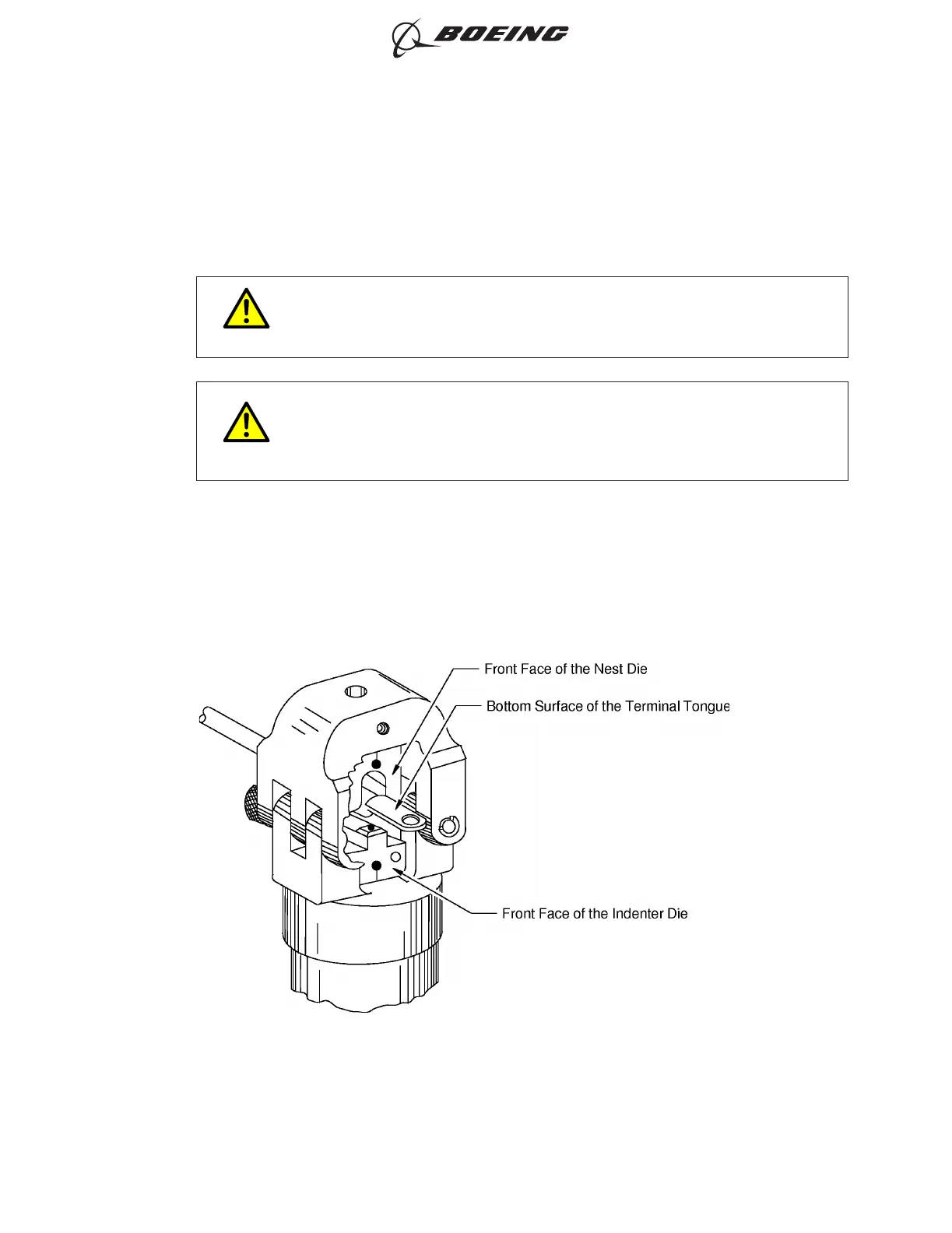

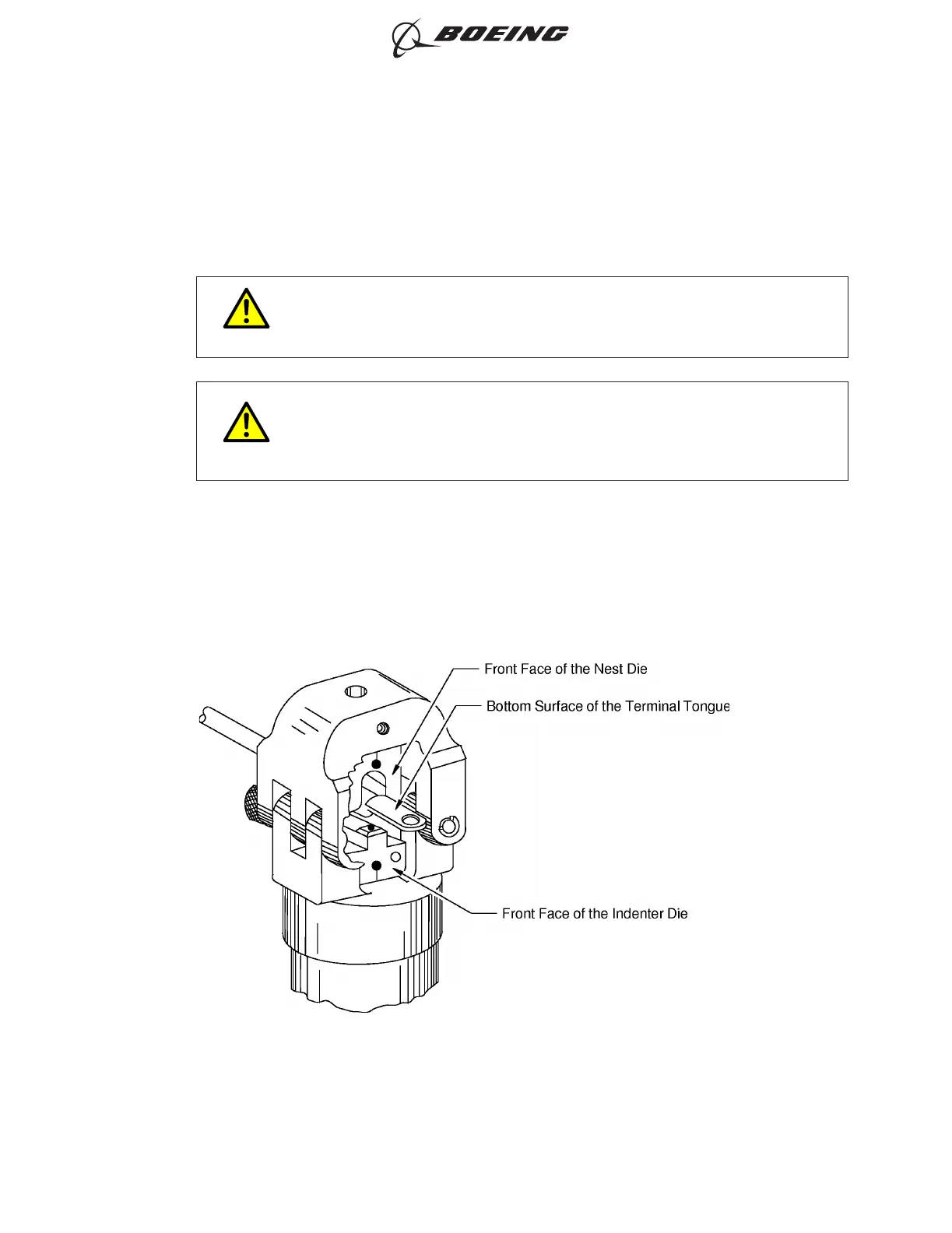

(7) Put the terminal lug and wire assembly in the nest die. Refer to Figure 16 for the position of the

terminal lug in the crimp tool and Figure 17 for the alignment of the terminal lug in the crimp dies.

Make sure that:

• The bottom surface of the of the terminal tongue is parallel with the flat surfaces of the nest

die

• The rear edge of the tongue ot the terminal lug is aligned with the front face of the dies.

POSITION OF THE TERMINAL LUG IN THE CRIMP TOOL

Figure 16

ASSEMBLY OF AMP (TYCO) COPALUM, MS25435 AND THOMAS & BETTS ALUMINUM

TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-14

Page 28

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...