3. TERMINAL INSTALLATION

A. Installation of Copper Terminals

CAUTION

DO NOT USE ANODIZED WASHERS, DYED WASHERS, OR STEEL WASHERS

ON THE STUD OR FASTENER BETWEEN THE WIRE TERMINAL AND THE

EQUIPMENT SURFACE OR THE TERMINAL BOARD. UNSATISFACTORY

PERFORMANCE OF THE ELECTRICAL CONNECTION OCCURS.

NOTE: Copper terminals are attached to:

• Either brass studs or brass screws with tin plated brass nuts

• Either steel studs or steel screws with self-locking steel nuts.

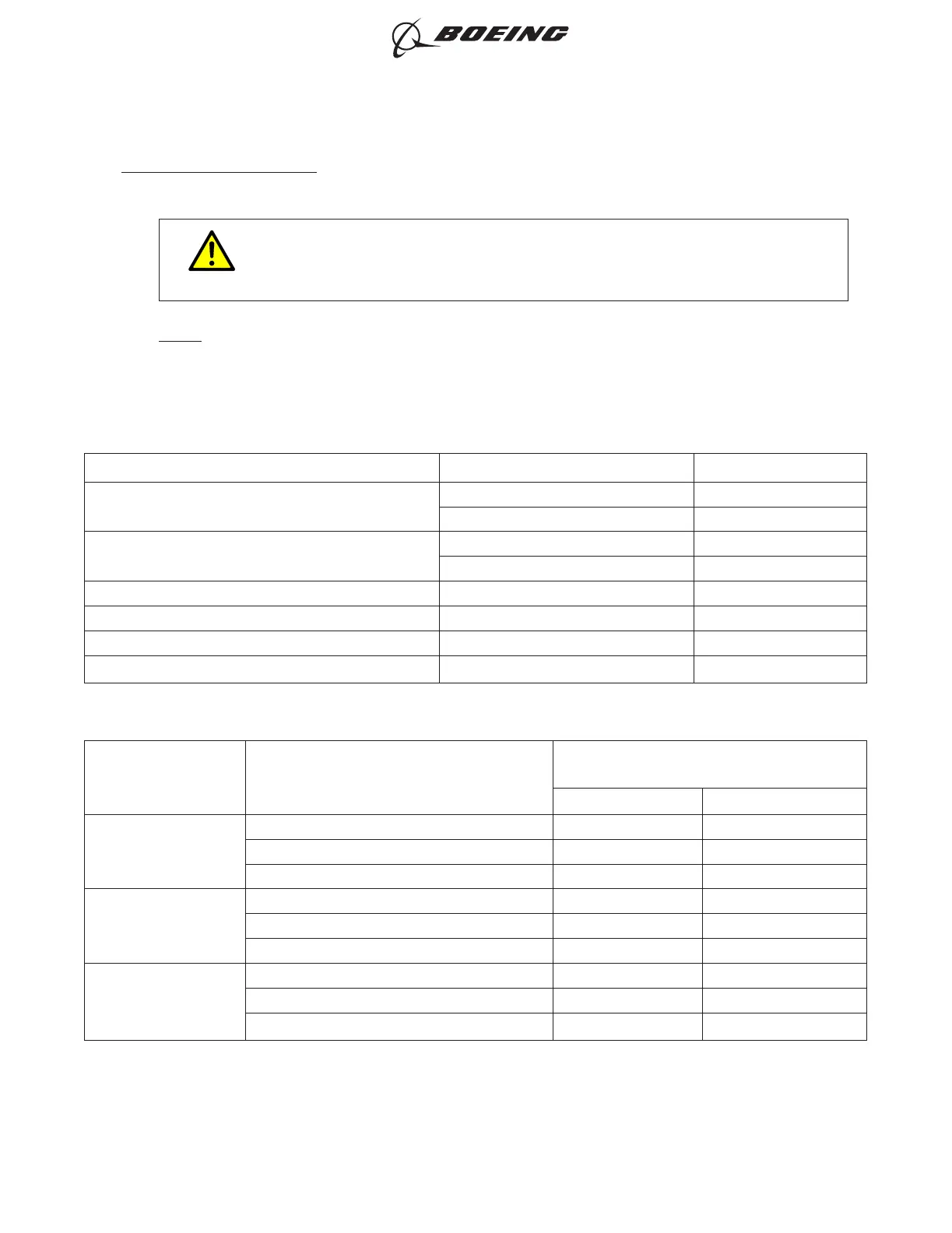

Table 4

INSTALLATION HARDWARE FOR COPPER TERMINALS

Hardware Part Number Supplier

Nut, Plain

MS35649- ( ) QPL

MS35650-( ) QPL

Nut, Self Locking

BACN10JC( ) Boeing

MS21042L( ) QPL

Lockwasher for Plain Nuts MS35338-( ) QPL

Lockwasher for Self Locking Nuts BACW10EC( )S Boeing

Washer, Flat NAS1149F( )P QPL

Washer, Spacer, Flat AN961-( ) QPL

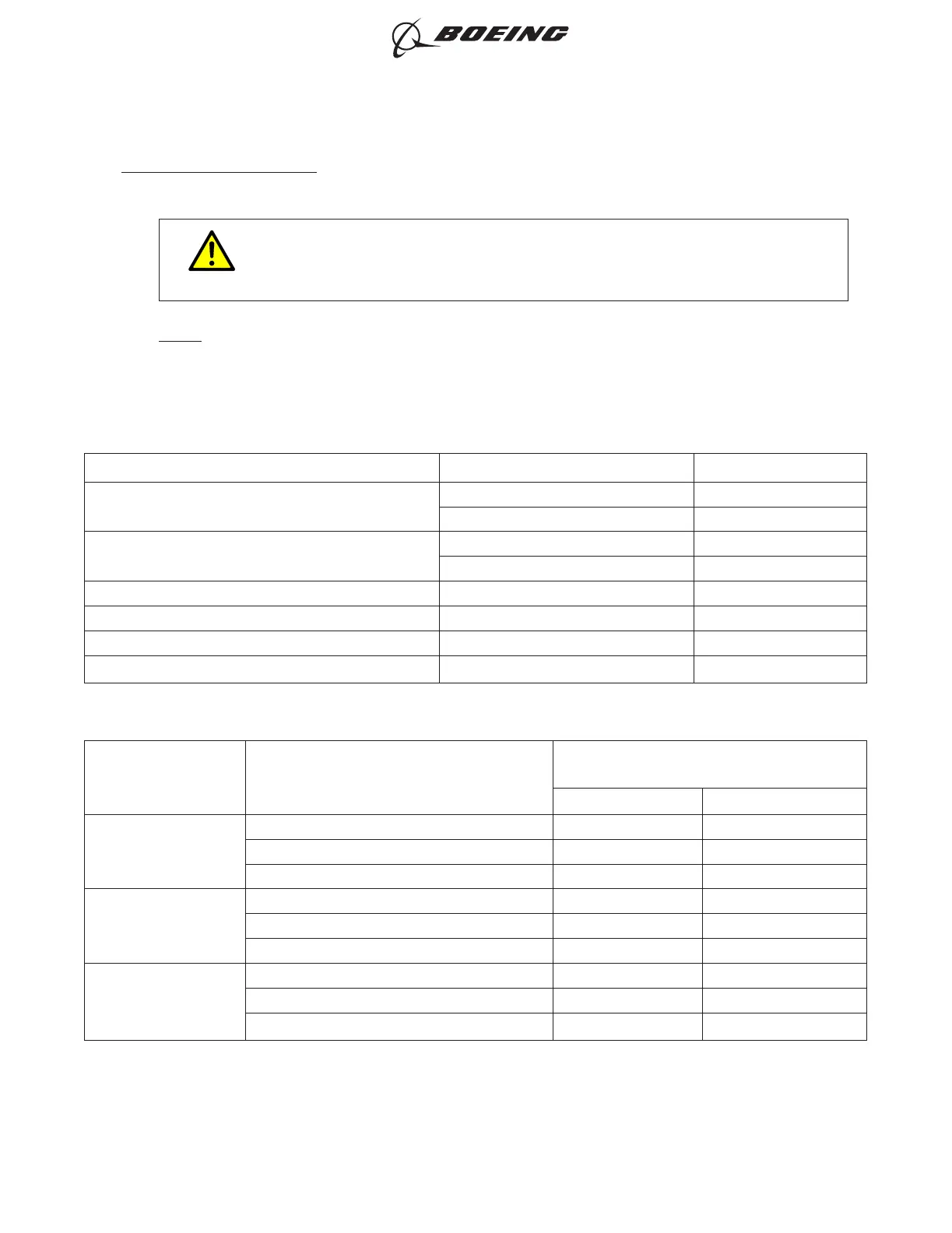

Table 5

INSTALLATION TORQUE FOR COPPER TERMINALS

Stud Size Hardware

Torque

(inch-pound)

Minimum Maximum

3-48

Nut, Plain 3.5 4.5

Nut, Plain With Lockwasher 3.5 4.5

Nut, Self-Locking 3.5 4.5

4-40

Nut, Plain 5.5 6.5

Nut, Plain With Lockwasher 5.5 6.5

Nut, Self-Locking 5.5 6.5

5-40

Nut, Plain 6 7

Nut, Plain With Lockwasher 6 7

Nut, Self-Locking 6 7

ELECTRICAL CONNECTION OF EQUIPMENT AND INSTALLATION OF TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-00

Page 10

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...