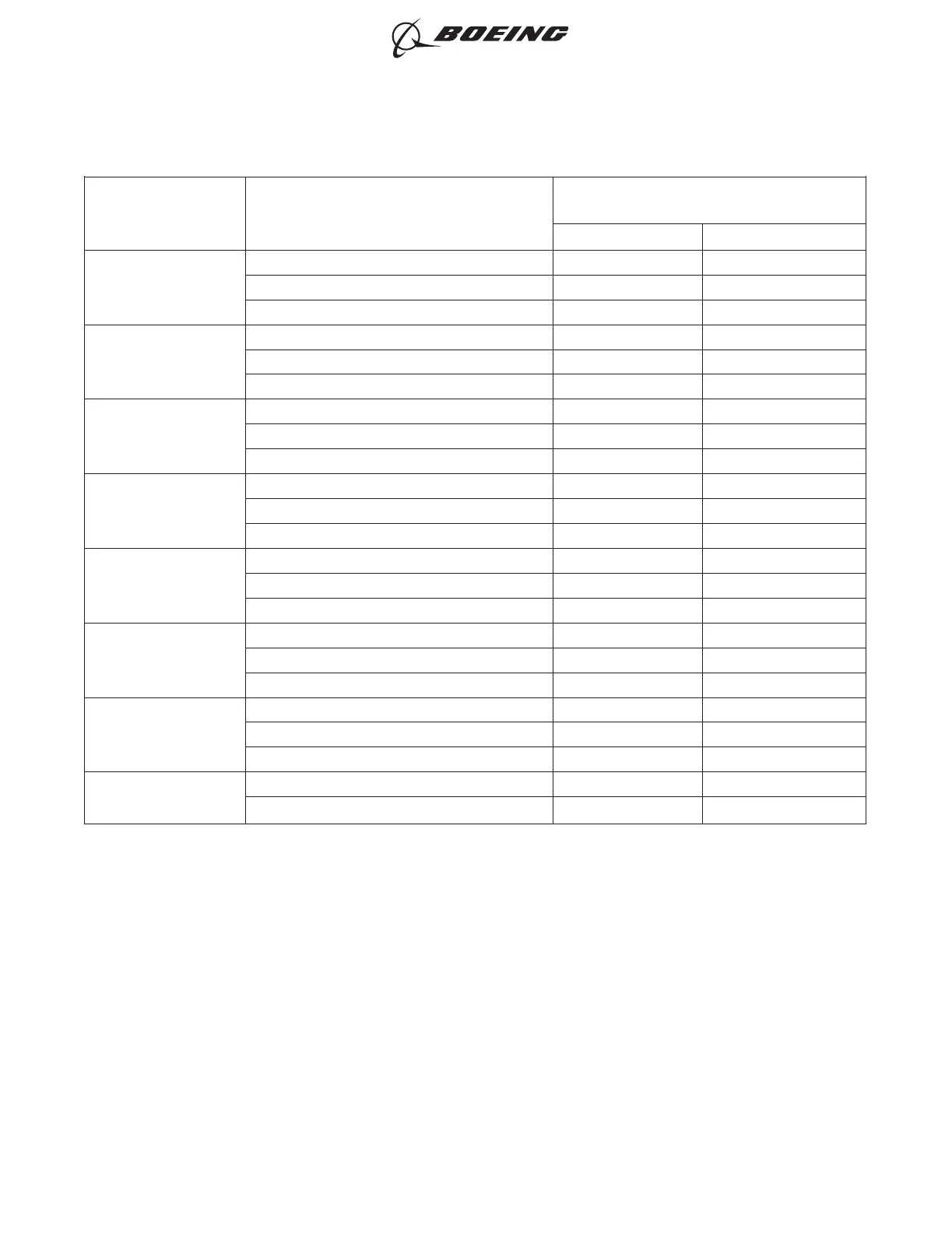

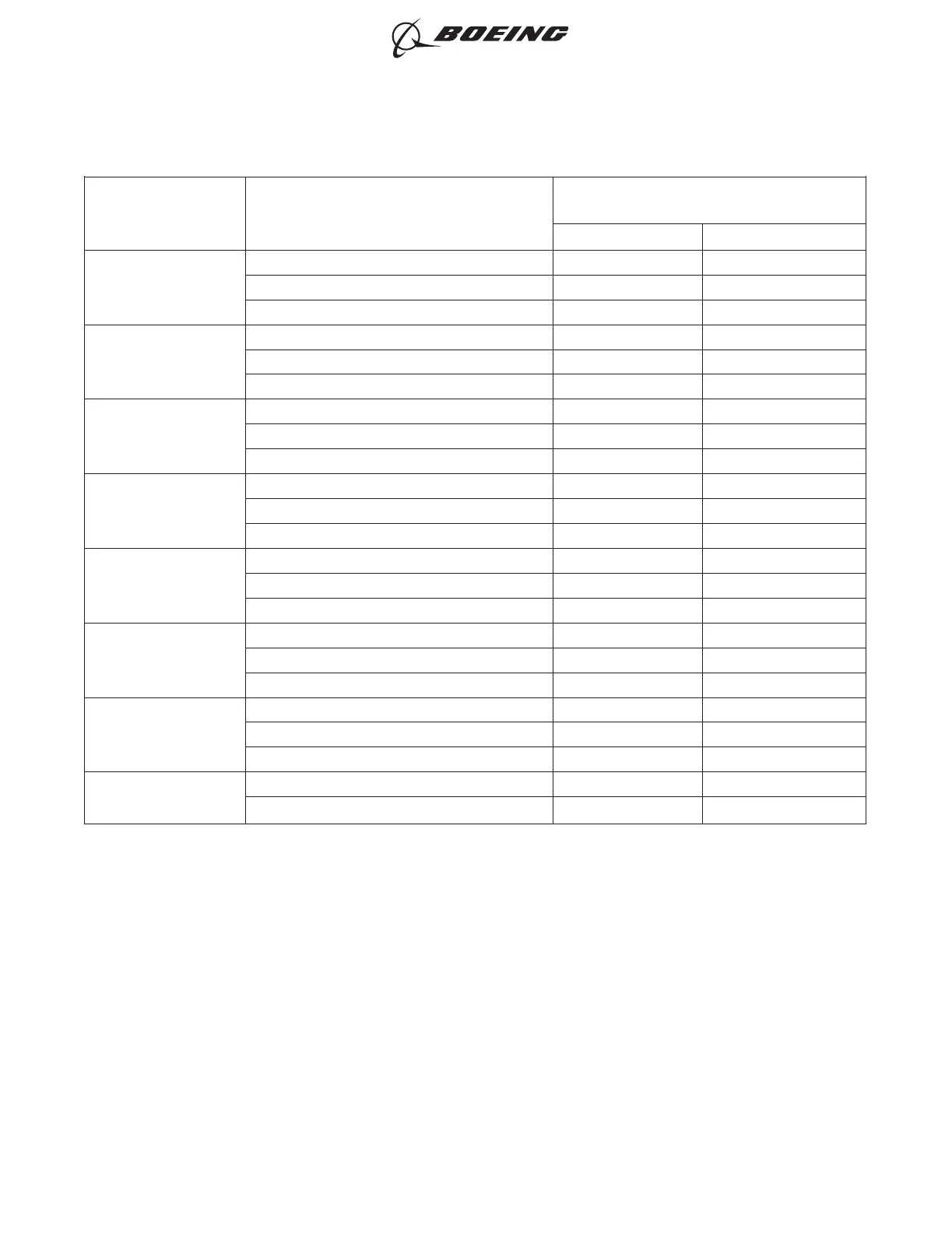

Table 5 INSTALLATION TORQUE FOR COPPER TERMINALS (Continued)

Stud Size Hardware

Torque

(inch-pound)

Minimum Maximum

6-32

Nut, Plain 7 9

Nut, Plain With Lockwasher 7 9

Nut, Self-Locking 7 9

8-32

Nut, Plain 12 16

Nut, Plain With Lockwasher 12 16

Nut, Self-Locking 12 16

10-32

Nut, Plain 28 32

Nut, Plain With Lockwasher 28 32

Nut, Self-Locking 28 32

12-24

Nut, Plain 23 25

Nut, Plain With Lockwasher 23 25

Nut, Self-Locking 23 25

1/4

Nut, Plain 65 85

Nut, Plain With Lockwasher 65 85

Nut, Self-Locking 65 85

5/16

Nut, Plain 115 135

Nut, Plain With Lockwasher 135 155

Nut, Self-Locking 135 155

3/8

Nut, Plain 150 180

Nut, Plain With Lockwasher 170 200

Nut, Self-Locking 180 210

1/2

Nut, Plain With Lockwasher 480 530

Nut, Self-Locking 480 530

(1) To install a single terminal on a stud, refer to Figure 9 and Table 4.

ELECTRICAL CONNECTION OF EQUIPMENT AND INSTALLATION OF TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-00

Page 11

Oct 15/2020D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...