(3) Make a selection of a power unit, crimp tool head, and die set from Table 11. Refer to Paragraph

2.H.. for terminal assembly process.

D. Wire Preparation for BACT13L Copalum Terminals

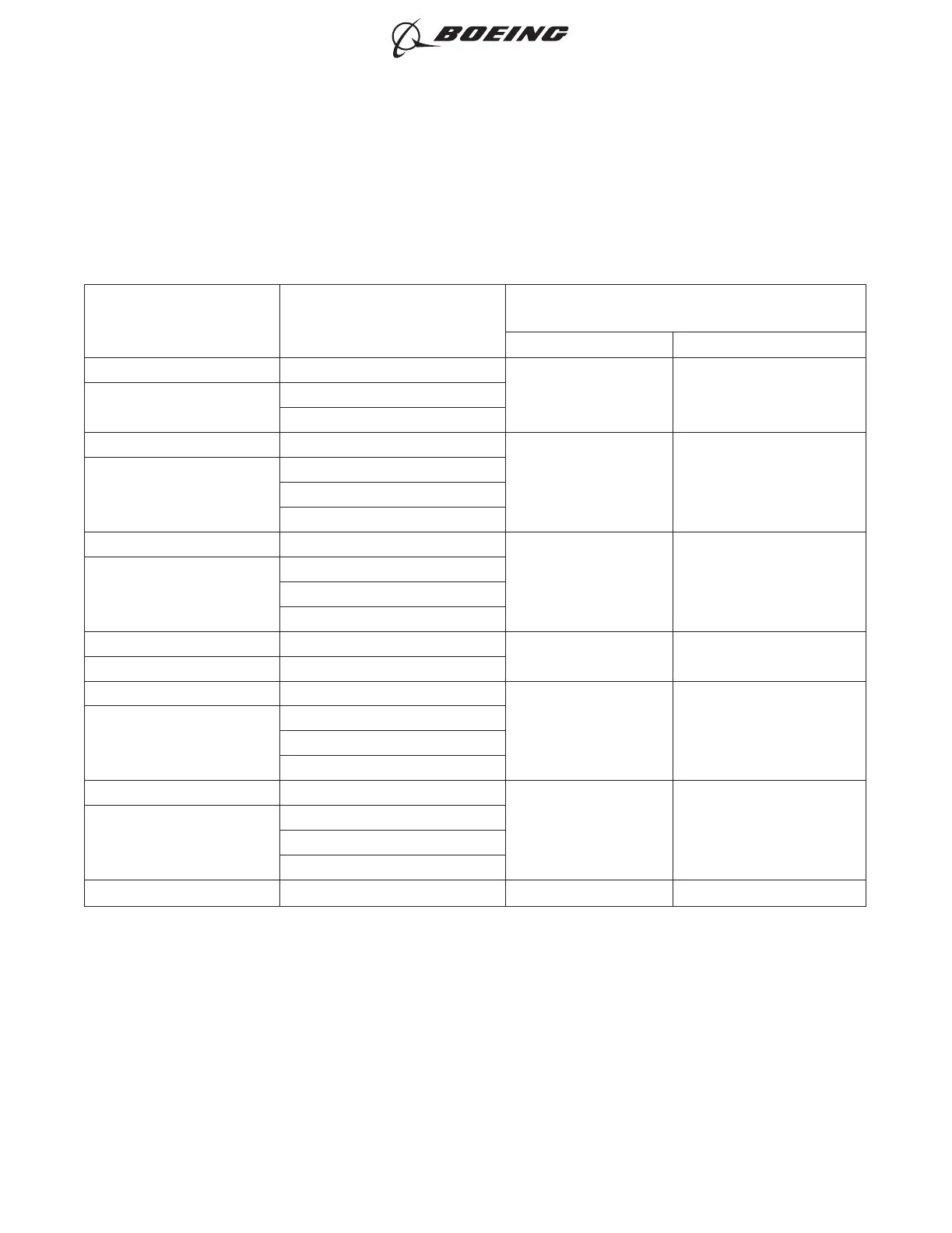

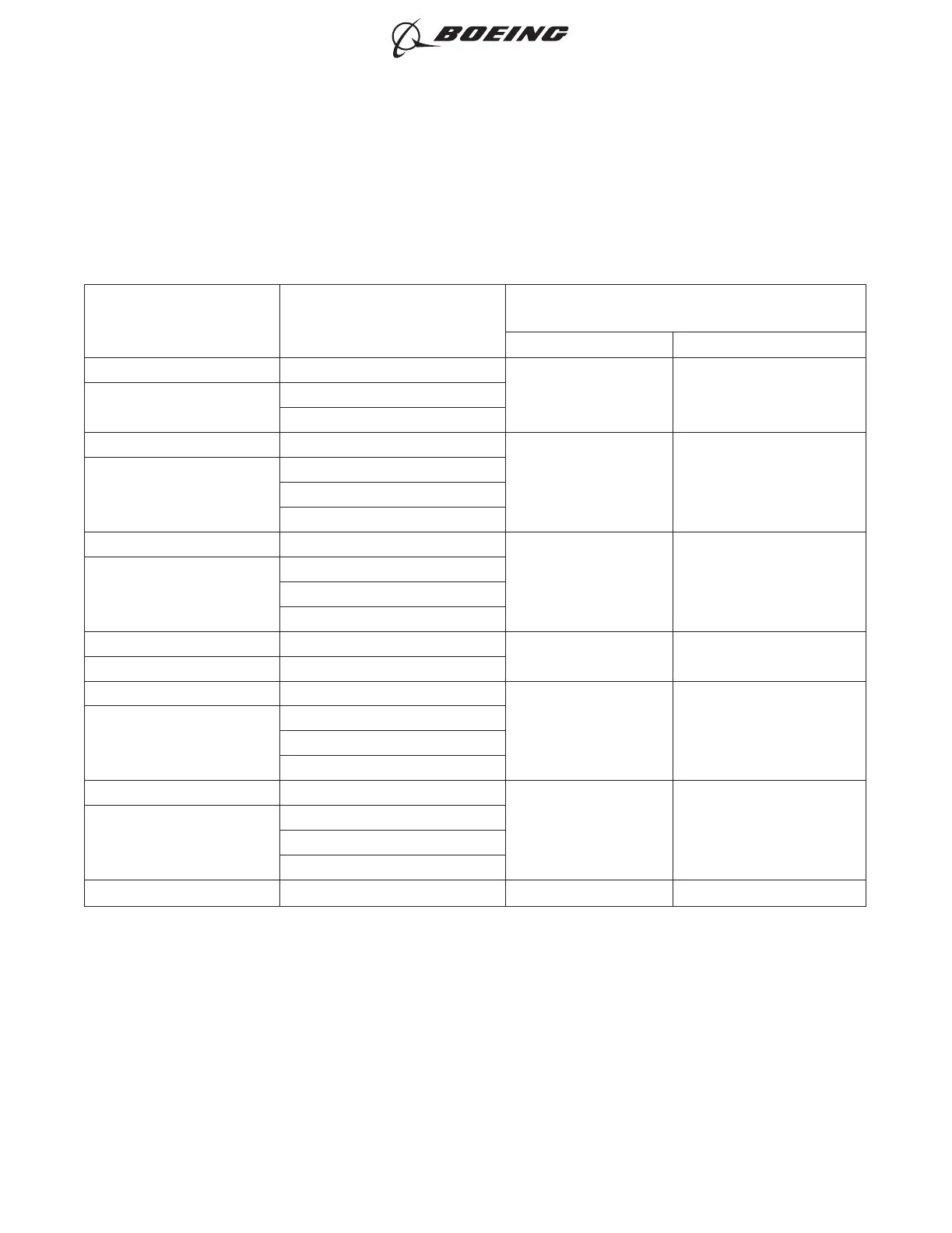

Table 14

WIRE INSULATION REMOVAL LENGTH FOR BACT13L TERMINAL LUGS

Crimp Barrel Size

(Part Mark)

Terminal Lug

Removal Length

(inch)

Target Tolerance

6AL - 8CU BACT13L-2

0.50 ±0.03

6AL 13-78

BACT13L-24A78

BACT13L-2A78

4AL - 6CU BACT13L-3

0.69 ±0.03

4AL 13-78

BACT13L-3A78

BACT13L-3A78-1

BACT13L-3A78-2

2AL - 4CU BACT13L-4

0.75 ±0.03

2AL 13-78

BACT13L-4A78

BACT13L-4A78-1

BACT13L-4A78-2

1/0AL - 2CU BACT13L-5

0.82 ±0.03

1/0AL 13-78 BACT13L-5A78

2/0AL - 1/0CU BACT13L-6

1.00 ±0.03

2/0AL 13-78

BACT13L-6A78

BACT13L-6A78-1

BACT13L-6A78-2

3/0AL - 2/0CU BACT13L-7

1.00 ±0.03

3/0AL 13-78

BACT13L-7A78

BACT13L-7A78-1

BACT13L-7A78-2

4/0AL 13-78 BACT13L-8A78 1.00 ±0.03

ASSEMBLY OF AMP (TYCO) COPALUM, MS25435 AND THOMAS & BETTS ALUMINUM

TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-14

Page 19

Feb 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...