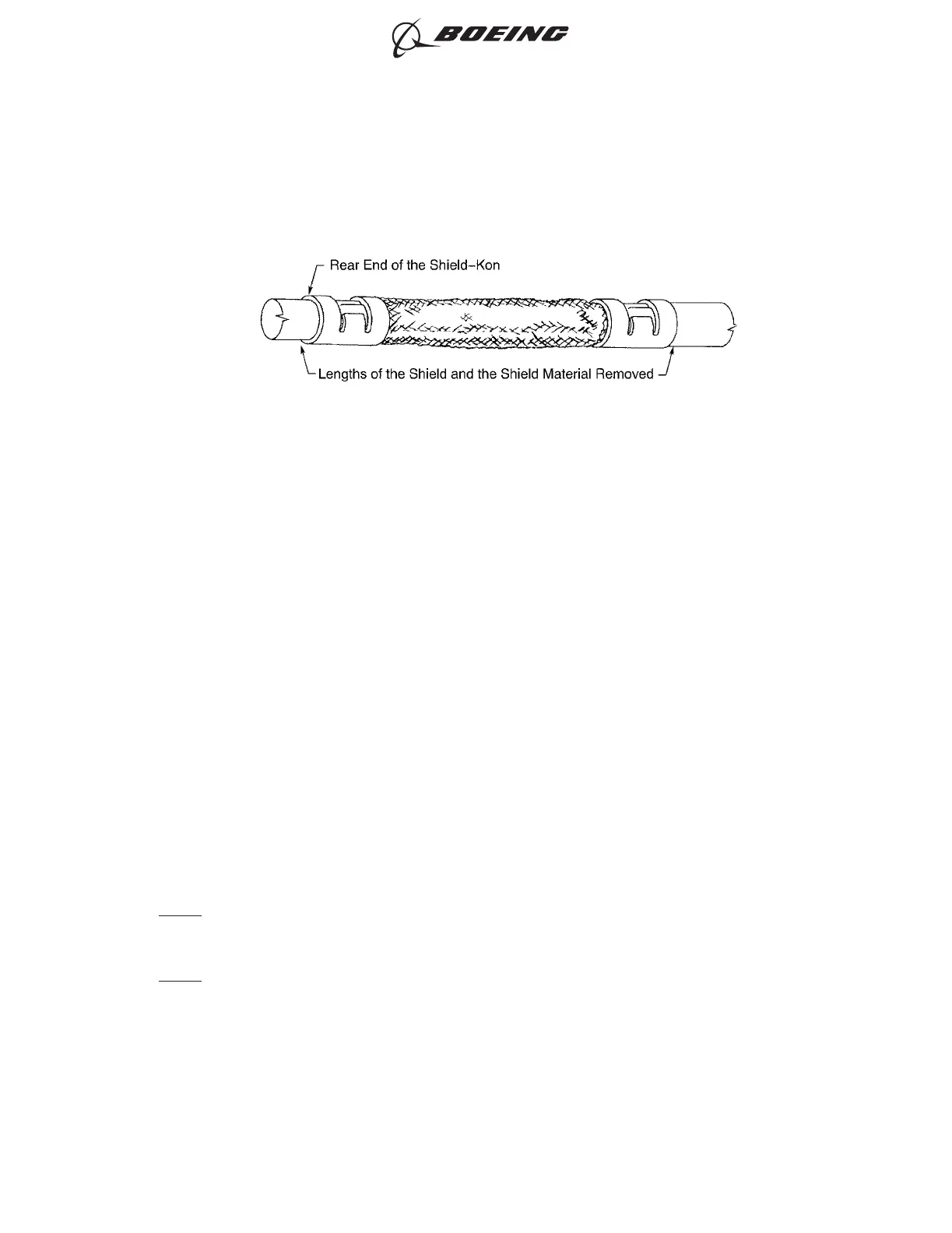

(j) Crimp the Shield-Kon.

(k) Remove the shield and the shield sleeve material that extend farther than the rear end of

the Shield-Kon on each end of the shield splice. Refer to Figure 193.

(14) Tightly wind a layer of the tape on the splice assembly.

Make sure that the layer of tape:

• Starts 0.50 inch ±0.25 inch farther than the rear end of the Shield-Kon at one end of the

splice

• Stops 0.50 inch ±0.25 inch farther than the rear end of the Shield-Kon at the other end of

the splice

• Makes a 50 percent overlap.

(15) Tightly wind a second layer of the tape on the splice assembly.

Make sure that the layer of tape:

• Starts 1 inch minimum farther than where the first layer of tape stops

• Stops 1 inch minimum farther than where the first layer of tape starts

• Makes a 50 percent overlap.

(16) Assemble a lacing tape wire harness tie on each end of the splice assembly approximately 0.25

inch from the end of the tape. Refer to Subject 20-10-11.

Make sure that the Temperature Grade of the lacing tape is Temperature Grade B or higher.

C. Sealed Splice Configurations for Shielded Wire and Cable - One Shielded Wire to One Shielded

Wire - Shield Kons, Tape, Sleeve

NOTE: The larger diameter Shield-Kons are no longer manufactured. For an alternative procedure to

assemble a splice for larger diameter shielded wire, refer to Paragraph 13.C. for the assembly

of a sealed splice with shield termination rings, shield terminator bands, tape and sleeve.

NOTE: If the correct diameter Shield-Kons are available, this procedure can be used:

For the conditions that are applicable for:

• The repair of a wire or a cable with a splice, refer to Subject 20-10-13

• The selection of the correct sealed splice configuration, refer to Paragraph 1.C.

SHIELD SPLICE ASSEMBLY

Figure 193

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 236

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...