(12) Shrink the short sleeve into position. Refer to Subject 20-10-14.

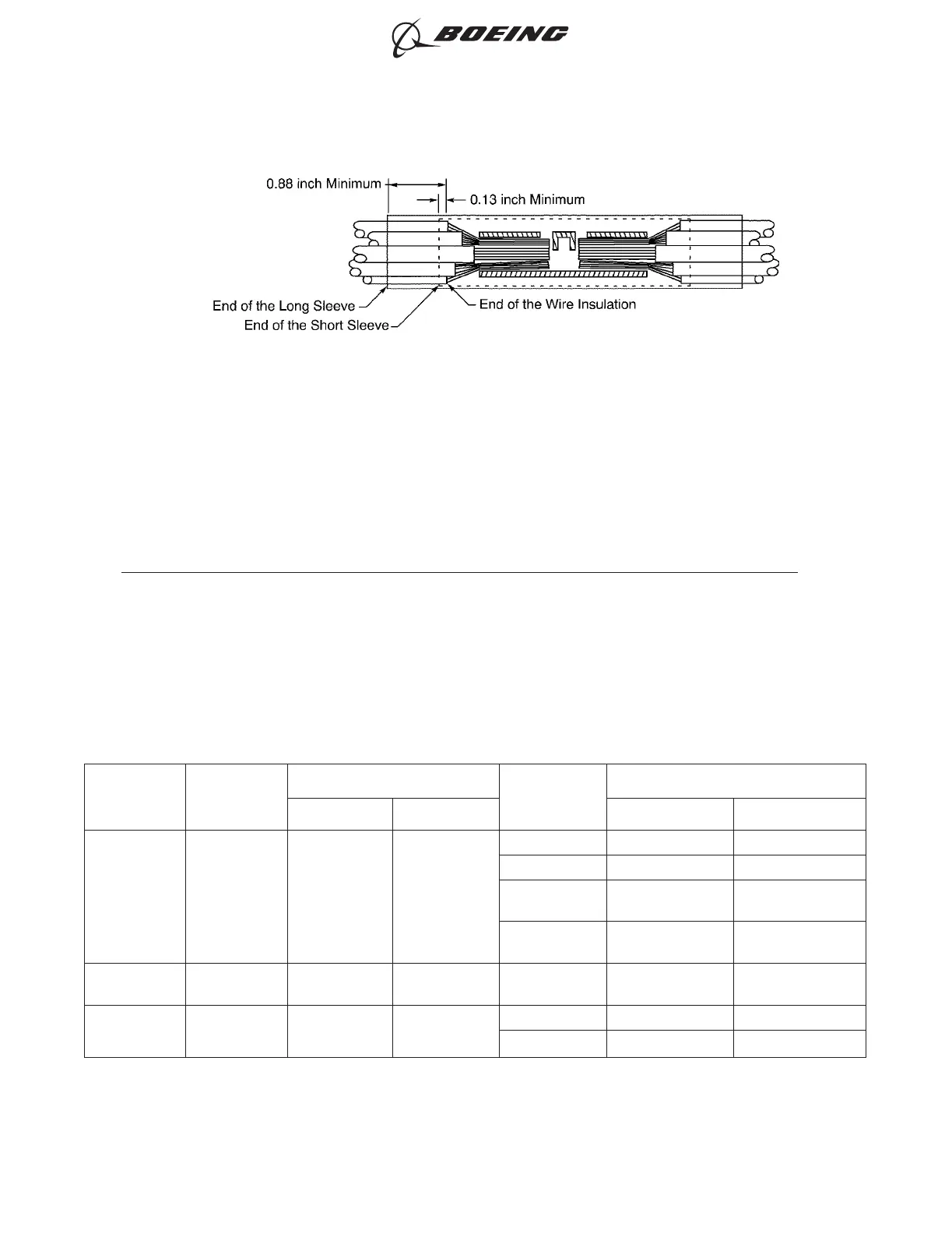

(13) Align the center of the long sleeve with the center of the splice. Refer to Figure 38.

Make sure that the long sleeve makes a 0.88 inch minimum overlap with the wire insulation on

each end of the splice assembly.

(14) Shrink the long sleeve into position. Refer to Subject 20-10-14.

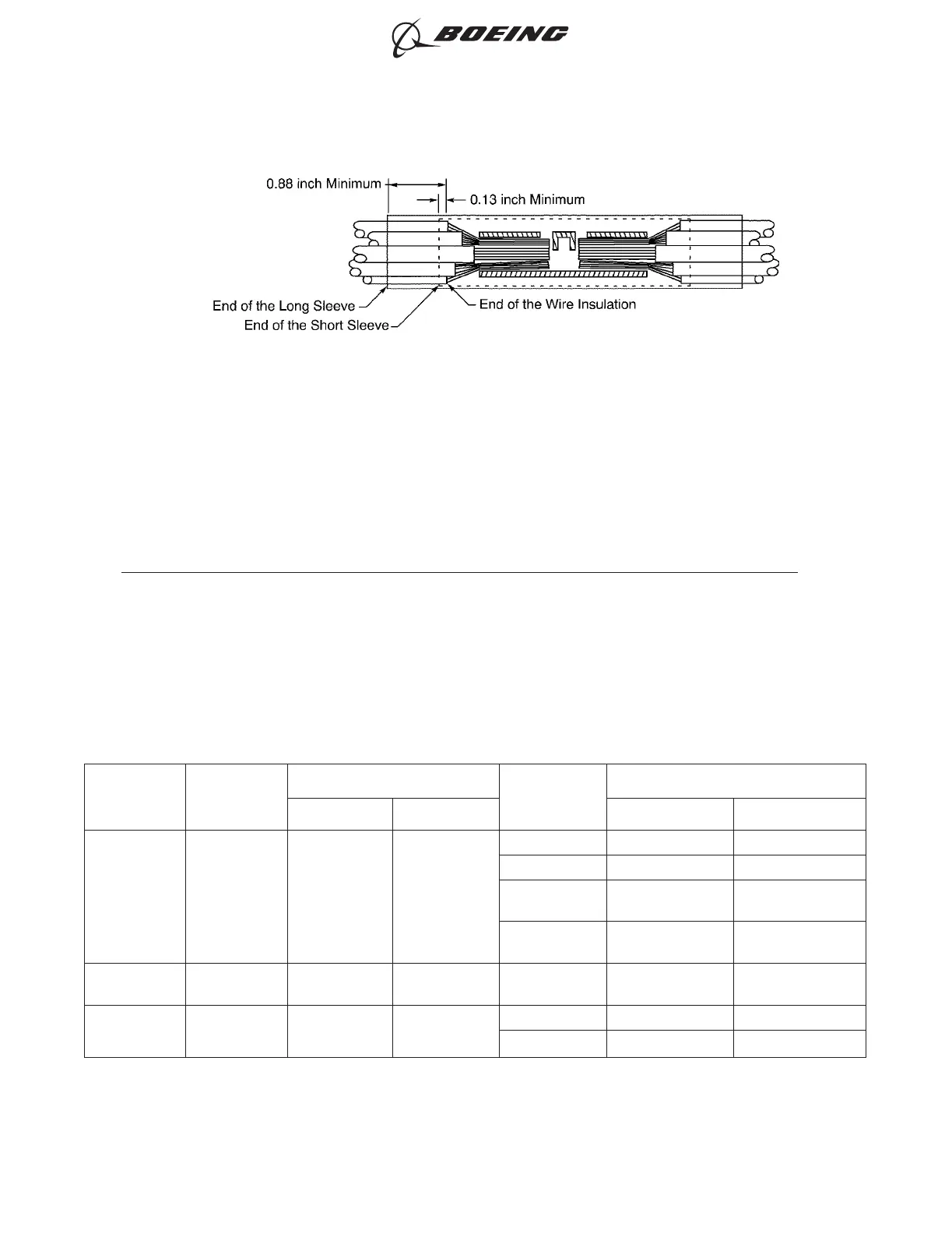

7. SEALED SPLICE CONFIGURATIONS FOR UNSHIELDED WIRES AND UNSHIELDED CABLES

A. Splice Assembly Configurations

For the conditions that are applicable for:

• The repair of a wire or a cable with a splice, refer to Subject 20-10-13

• The selection of the correct sealed splice configuration, refer to Paragraph 1.C.

To calculate the CAU of the conductor, refer to Table 4.

Table 66

SEALED SPLICE ASSEMBLY CONFIGURATIONS

One End of

Splice

Assembly

Other End of

Splice

Assembly

CAU Range

Applicable

Condition

Splice Assembly

Minimum Maximum Configuration Procedure

One Wire One Wire 3 457

Fuel Vapor Tape, Ties Paragraph 7.B.

No Fuel Vapor Tape, Ties Paragraph 7.B.

Fuel Vapor

Sealant, Sleeve,

Ties

Paragraph 7.C.

No Fuel Vapor

Sealant, Sleeve,

Ties

Paragraph 7.C.

One Wire One Wire - - No Fuel Vapor

Sleeves - Resistor

or Diode

Paragraph 7.M.

One Wire Two Wires 3 457

Fuel Vapor Tape, Ties Paragraph 7.D.

No Fuel Vapor Tape, Ties Paragraph 7.D.

POSITION OF THE SLEEVES ON THE SPLICE ASSEMBLY

Figure 38

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 79

Feb 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...