• The large solder sleeve

• The seal sleeve.

Make sure that:

• The small end of the small solder sleeve is put on the cable first

• The large end of the large solder sleeve is put on the cable first.

(5) If the splice kit does not have seal inserts and the solder sleeves are the same size put these

splice assembly components on Cable A in this sequence:

• The outer sleeve

• A solder sleeve

• The shield material

• The other solder sleeve

• The seal sleeve.

Make sure that:

• The small end of the first solder sleeve is put on the cable first.

• The large end of the second solder sleeve is put on the cable first.

(6) Put a seal sleeve on Wire A.

C. Kit Group P1N1, P2N1, P3N1 or P4N1 - One Class 1 Cable to One Class 1 Cable

For the conditions that are applicable for this procedure, refer to Paragraph 2.B..

Refer to Figure 32.

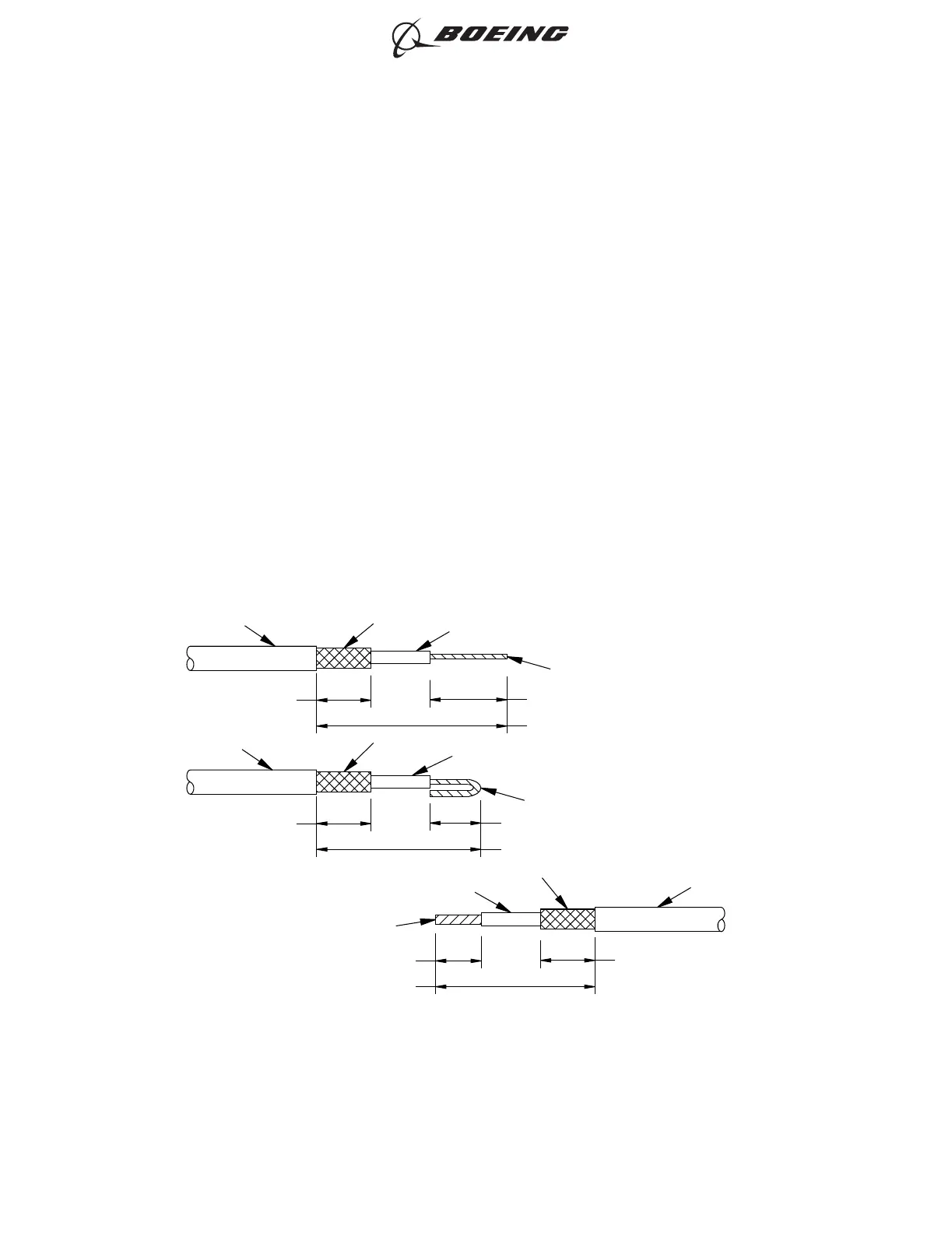

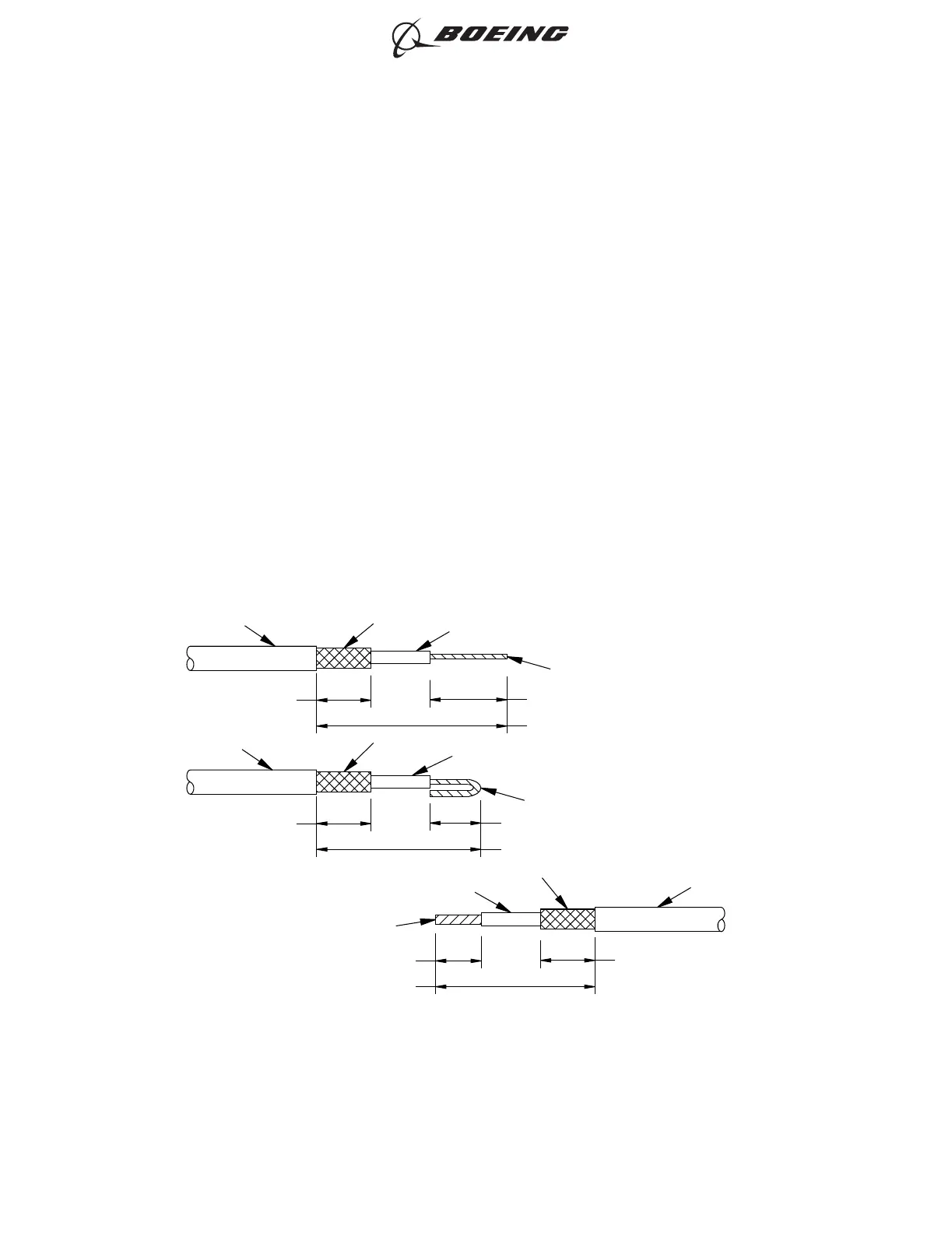

CONDUCTOR

INSULATION

SHIELD

1.5 ±0.05 INCHES

0.5 ±0.05 INCH

CABLE B

JACKET

0.3 ±0.05 INCH

INSULATION

SHIELD

CABLE A

CABLE A

CONDUCTOR

1.5 ±0.05 INCHES

0.3 ±0.05 INCH0.5 ±0.05 INCH

JACKET

INSULATION

SHIELD

CONDUCTOR

JACKET

0.5 ±0.05 INCH

1.8 ±0.05 INCHES

0.6 ±0.05 INCH

2449595 S00061545759_V2

ONE CLASS 1 CABLE TO ONE CLASS 1 CABLE

Figure 32

ASSEMBLY OF BACS52P SERIES AND D-150-0300 SERIES SHIELDED SPLICE ASSEMBLIES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-20

Page 132

Feb 15/2022D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...