If a terminal lug that has the same size hole as the stud is not available, these configurations of

terminals lugs and studs are satisfactory alternatives:

• A terminal lug that has a size 10 hole on a size 8 stud

• A terminal lug that has a size 8 hole on a size 6 stud

• A terminal lug that has a size 6 hole on a size 4 stud

• A terminal lug that has a size 4 hole on a size 2 stud.

These conditions are applicable for studs that have more than one terminal lug:

• The maximum number of terminal lugs that can be attached to a stud is 4

• The largest terminal lug must be installed first at the base of the stud

• The remaining terminal lugs must be installed in order of decreasing size.

All electrical connections that are open to the air in the flammable leakage zones must be sealed.

Refer to Paragraph 4.

NOTE: It is not necessary to seal insulated splices.

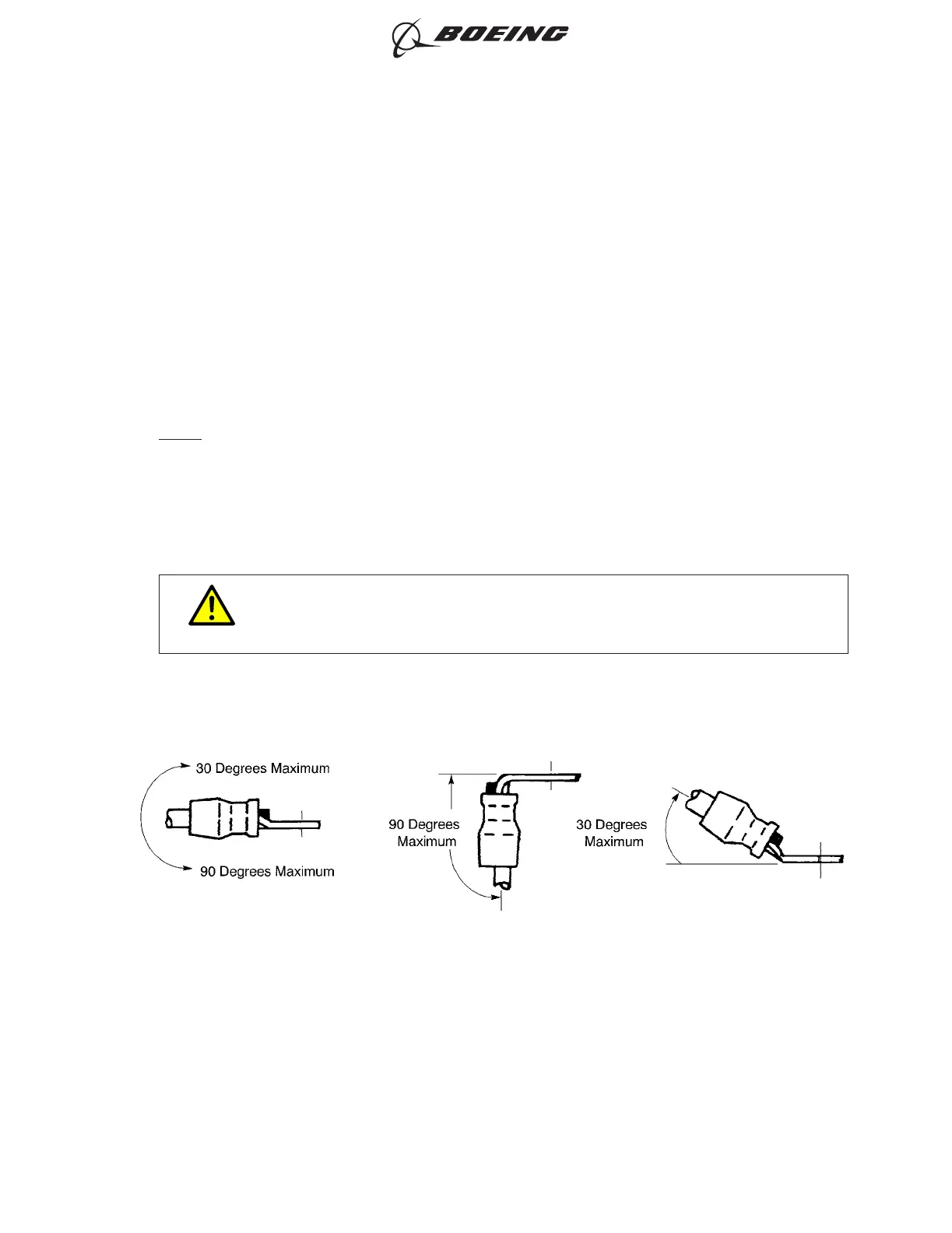

B. Permitted Bends of a Terminal

Uninsulated and preinsulated terminals can be bent:

• A maximum of 90 degrees for installation in restricted spaces

• A maximum of 30 degrees for installation on a terminal block.

Refer to Figure 1.

CAUTION

A TERMINAL CAN BE BENT ONLY ONCE AND ONLY IN EITHER DIRECTION

THAT IS SHOWN IN FIGURE 1. DO NOT USE TERMINALS THAT HAVE BEEN

BENT BEFORE.

Make sure that:

• The bend radius is not greater than 5/32 inch ±1/32 inch

• There are no cracks in the bend area.

PERMITTED DIRECTION AND ANGLE OF THE BEND OF A TERMINAL

Figure 1

ELECTRICAL CONNECTION OF EQUIPMENT AND INSTALLATION OF TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-00

Page 4

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...