B. Splice Assembly Cable Preparation

(1) Make a selection of a splice assembly configuration from Table 7.

NOTE: Table 7 gives the special configurations of cable preparation.

(2) If the wiring configuration and the splice kit are not specified in Table 7, make a selection of a

splice assembly configuration from Table 6.

NOTE: Table 6 gives the standard configurations of cable preparation.

(3) If a build-up sleeve is specified, put a 1.0 inch ±0.1 inch length of the specified sleeve on the

applicable wiring. Refer to Table 4.

(4) Prepare the end of each cable.

Refer to:

• The applicable splice assembly configuration

• Subject 20-00-15 for the procedure to remove the cable jacket

• Subject 20-00-15 for the procedure to remove the wire insulation.

(5) If it is specified, fold the conductor or conductors back.

(6) If a filler wire is specified:

(a) Cut a 1.0 inch to 2.0 inch length of the filler wire.

(b) Remove 0.30 inch ±0.05 inch of the insulation from the end of the wire. Refer to

Subject 20-00-15.

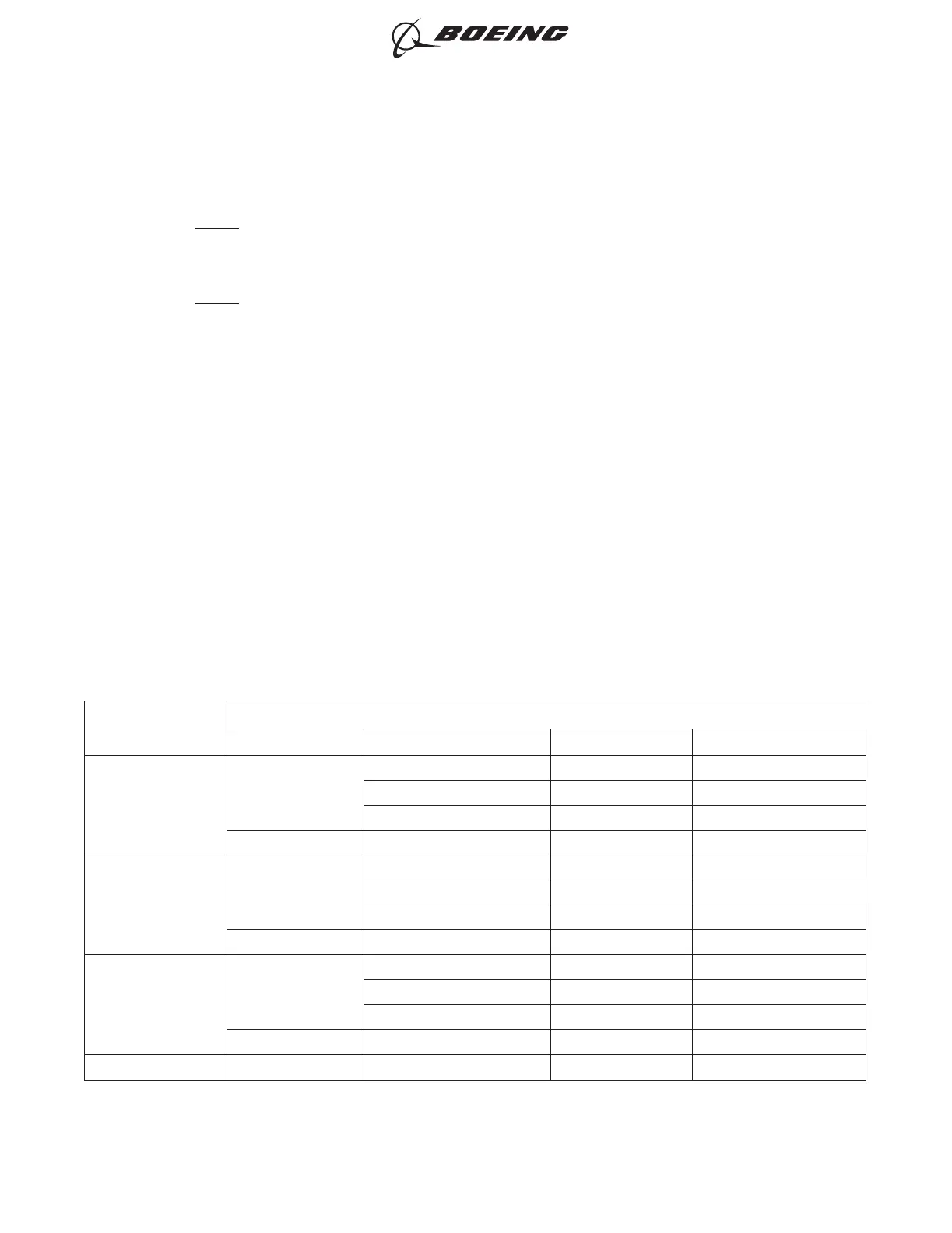

C. Assembly of the Conductor Splice

Table 8

CONDUCTOR SPLICE CRIMP TOOLS

Crimp Barrel Size

Crimp Tool

Type Basic Unit Die or Nest Color Supplier

26-20

Hand

AD-1377 Red Tyco

ST956C Red Boeing

ST956D Red Boeing

Power PMTB-232 Red Daniels

20-16

Hand

AD-1377 Blue Tyco

ST956C Blue Boeing

ST956D Blue Boeing

Power PMTB-232 Blue Daniels

16-12

Hand

AD-1377 Yellow Tyco

ST956C Yellow Boeing

ST956D Yellow Boeing

Power PMTB-232 Yellow Daniels

12-10 Hand 46447 12-10 AMP

ASSEMBLY OF BACS52T SERIES SHIELDED SPLICE ASSEMBLIES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-21

Page 21

Oct 15/2020D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...