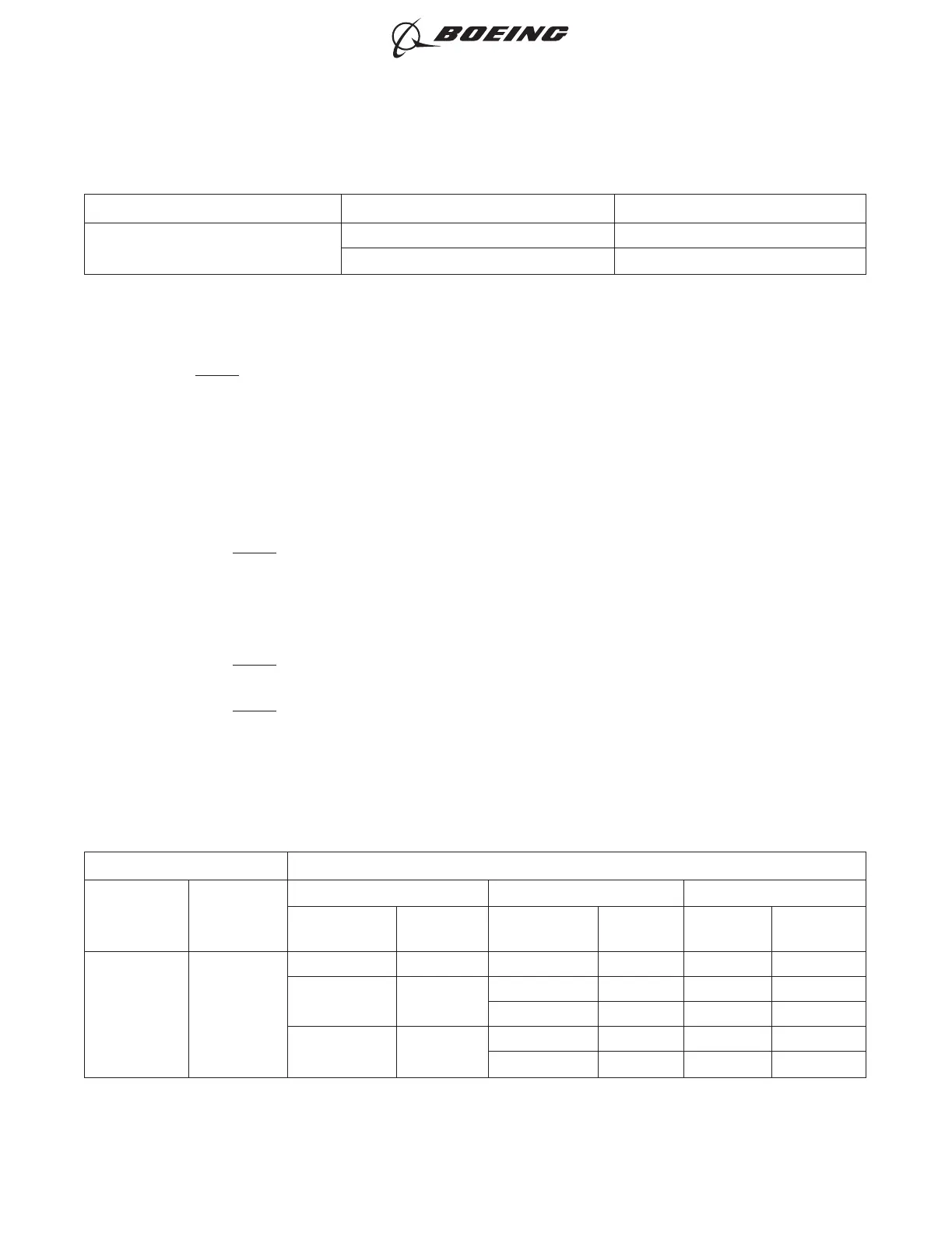

Table 19

NECESSARY MATERIAL

Material Part Number Supplier

Heat Shrinkable Sleeve

DWP-125 Raychem

MWSF Remtek

(1) Make a selection of one of these types of insulation sleeves:

• A heat shrinkable sleeve

• A cold shrinkable sleeve.

NOTE: A heat gun is necessary to install a heat shrinkable sleeve.

(2) If the selection is a heat shrinkable sleeve:

(a) Make a selection of heat shrinkable sleeve. Refer to Table 19.

(b) Cut a length of the selected heat shrinkable sleeve that is equal to the length of the crimp

area of the terminal plus 0.5 inch.

Make sure that the sleeve has the smallest diameter that can move over the terminal and

the wire.

NOTE: Refer to Subject 20-00-11 for alternative heat shrinkable sleeve.

(c) Put the sleeve on the wire. Refer to Paragraph 2.N. for the terminal lug assembly process.

(3) If the selection is a cold shrinkable sleeve:

(a) Make a selection of a cold shrinkable sleeve from Table 18.

NOTE: If the wire size is not given in Table 18, a heat shrinkable sleeve must be used.

Refer to Step 2.F.(2).

NOTE: The number after the dash in the part number is the length of the sleeve after the

sleeve is installed.

(b) Put the sleeve on the wire. Refer to Paragraph 2.N. for the terminal lug assembly process.

G. Assembly of Tyco/AMP Copalum Terminals and Aluminum Terminals

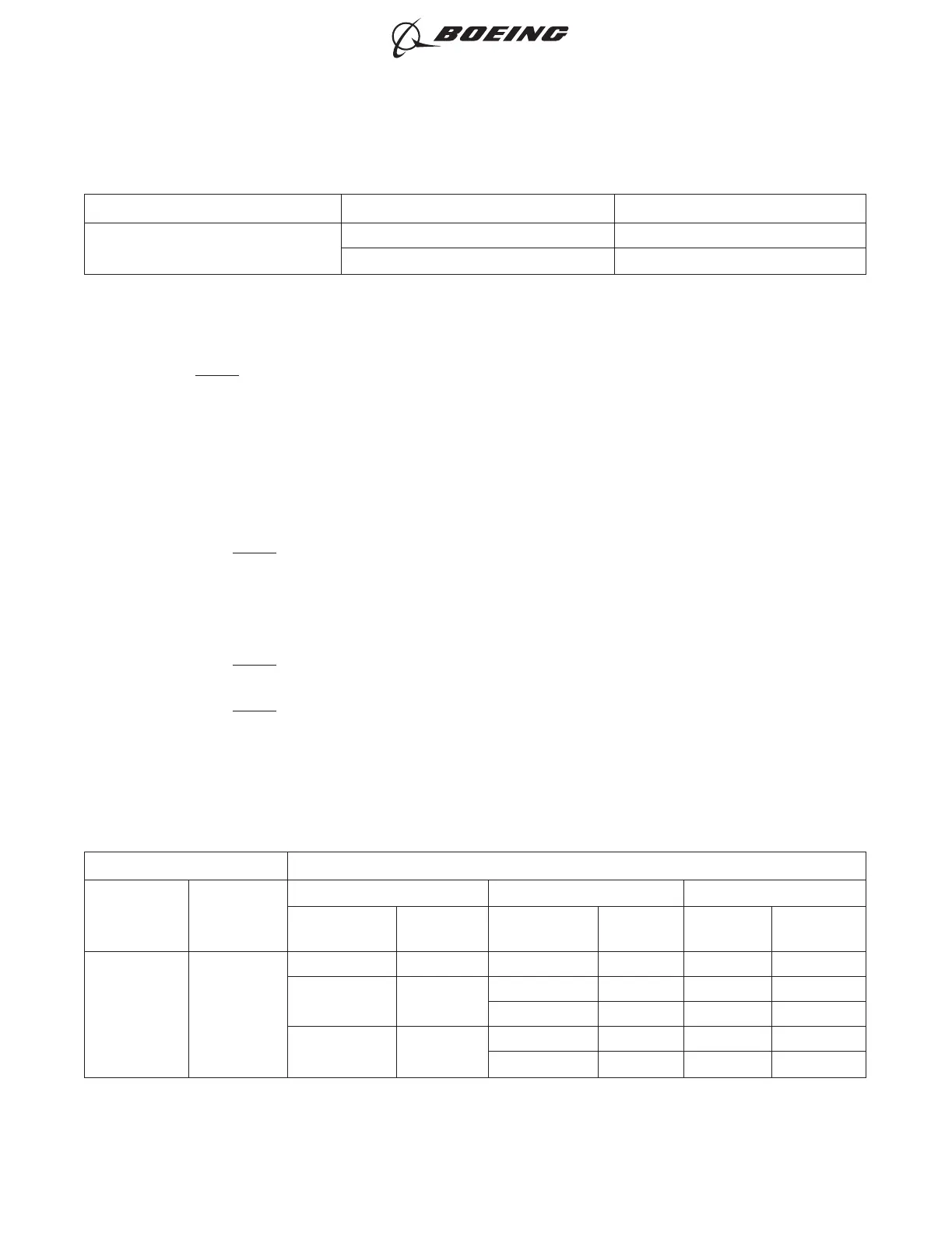

Table 20

CRIMP TOOLS FOR AMP COPALUM TERMINALS

Crimp Barrel Crimp Tool

Aluminum

Wire Size

(AWG)

Copper Wire

Size (AWG)

Basic Unit Head Die Set

Part Number Supplier Part Number Supplier

Part

Number

Suppiler

8 10

1804700-1 AMP 1752787-1 AMP 68006 AMP

122271-1 AMP

69066 AMP 68006 AMP

58422-1 AMP 68006 AMP

69120 AMP

69066 AMP 68006 AMP

58422-1 AMP 68006 AMP

ASSEMBLY OF AMP (TYCO) COPALUM, MS25435 AND THOMAS & BETTS ALUMINUM

TERMINALS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-14

Page 23

Oct 15/2015D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...