D. Terminal Lug Installation on an Amphenol 465-8238 Terminal Board

These conditions are applicable:

• The tongue of a BACT13T terminal lug does not have a bend that is more than 0.15 inch from the

longitudinal axis of the bottom surface of the tongue; refer to Figure 16 and Figure 17

• The maximum number of terminal lugs that can be attached to a stud is 3

• For the installation of two terminal lugs from the same side of the terminal board, the bottom

surface of the tongues of the terminal lugs must be put together

• The BACT13T breakaway terminal lug must be put on the studs first

• The bottom surface of the tongue of the BACT13T breakaway terminal lug must be flat against

the body of the terminal board

• The remaining terminal lugs must be put on the studs in the order of decreasing size

• Each nut must be torqued 200 inch-pounds to 240 inch-pounds.

(1) Make a selection of a washer from Table 8/NECESSARY INSTALLATION COMPONENTS.

Table 8

NECESSARY INSTALLATION COMPONENTS

Washer Stud Size Outside Diameter (inch) Quantity

BACW10P254CA 3/8 0.87 2

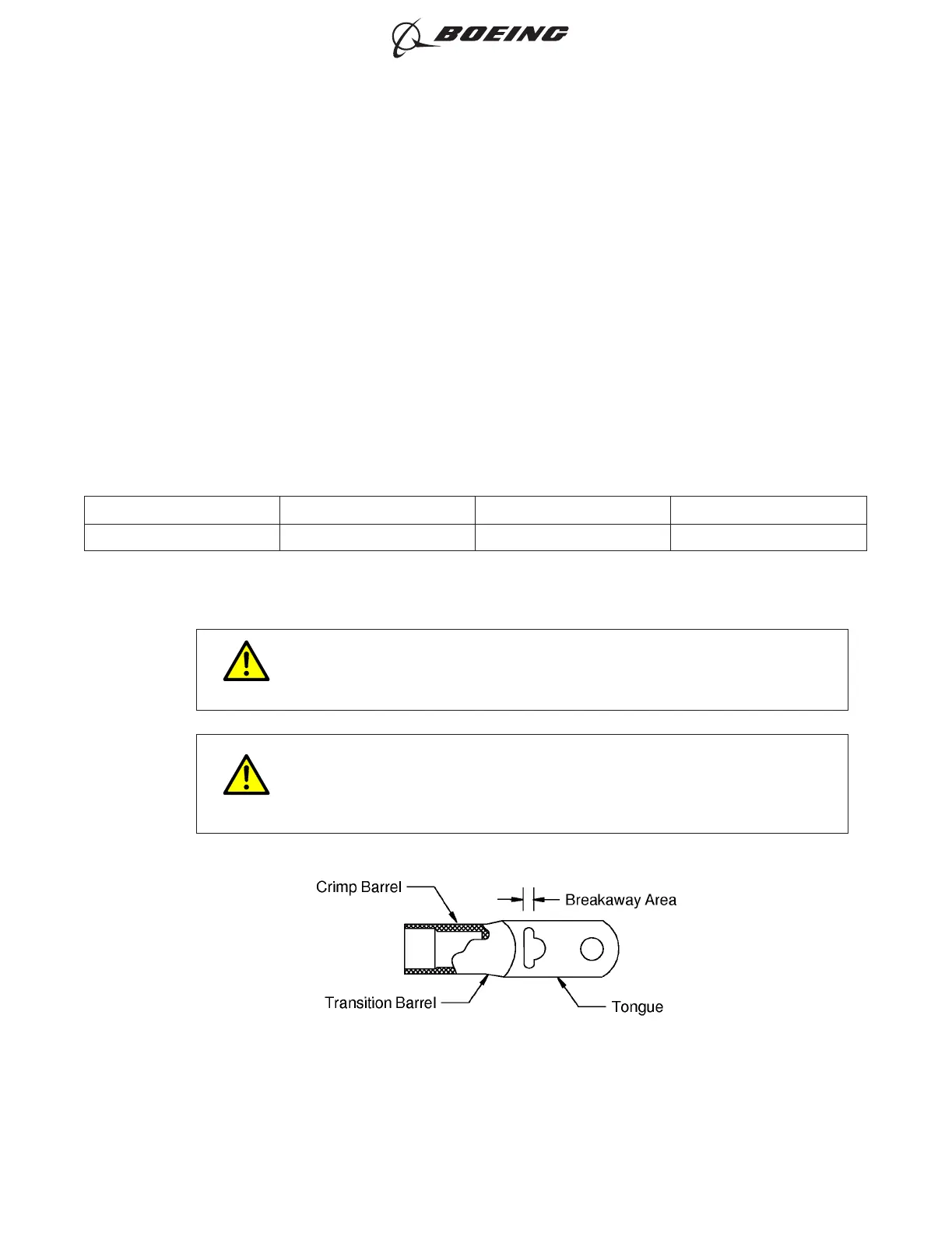

(2) Examine the breakaway terminal lug assembly. Refer to Figure 15

Make sure that the tongue of the terminal lug does not have a bend that is more than 0.15 inch

from the longitudinal axis of the bottom surface of the tongue. Refer to Figure 16 and Figure 17.

CAUTION

IF THE TONGUE OF A BACT13T TERMINAL LUG HAS A BEND THAT IS

MORE THAN 0.15 INCH FROM THE LONGITUDINAL AXIS OF THE

BOTTOM SURFACE OF THE TONGUE, THE TERMINAL LUG IS DAMAGED

AND MUST NOT BE INSTALLED.

CAUTION

IF THE TONGUE OF BACT13T TERMINAL LUG HAS A BEND THAT IS

MORE THAN 0.15 INCH FROM THE LONGITUDINAL AXIS OF THE

BOTTOM SURFACE OF THE TONGUE, DO NOT TRY TO MAKE THE

TONGUE STRAIGHT. THE TERMINAL LUG IS DAMAGED AND MUST NOT

BE INSTALLED.

BACT13T BREAKAWAY TERMINAL LUG

Figure 15

ELECTRICAL CONNECTION OF EQUIPMENT AND INSTALLATION OF TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-00

Page 20

Jun 15/2018D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...