Make sure that:

• The maximum number of terminal lugs attached to a stud is 4

• The largest terminal lug is put on the stud first

• The remaining terminal lugs are put on the stud in the order of decreasing size

• After the terminals and hardware are installed, you can see a minimum of 2 1/2 stud threads

beyond the nut.

(4) For each stud, make a selection of:

• A new BACN10HY6AM (or equivalent) nut

• A new NAS1149E0632R flat washer

• A new BACW10EC6C lockwasher.

(5) Put the flat washer, the lockwasher, and the nut on each stud. Refer to Figure 13.

(6) Torque each nut 200 inch-pounds to 240 inch-pounds.

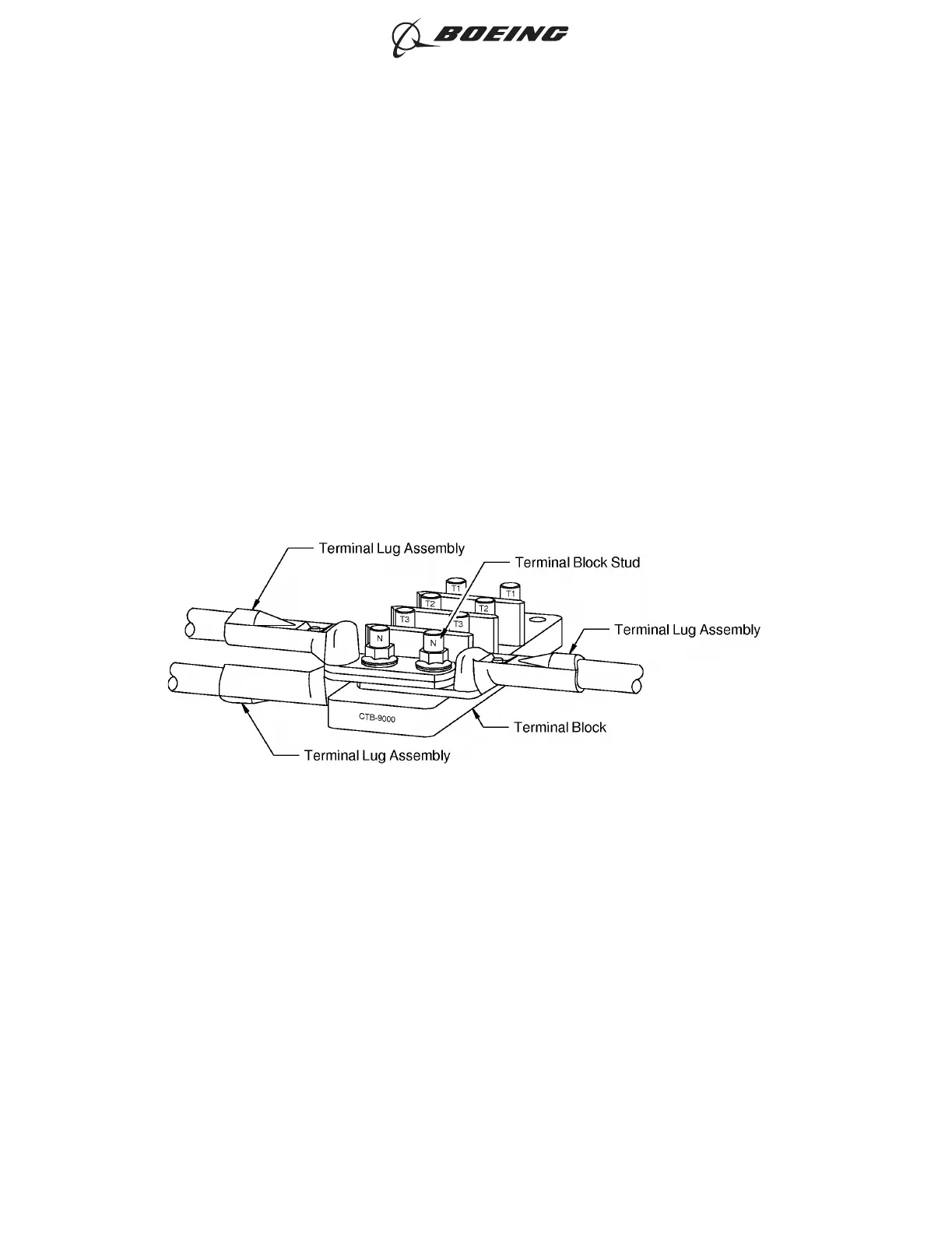

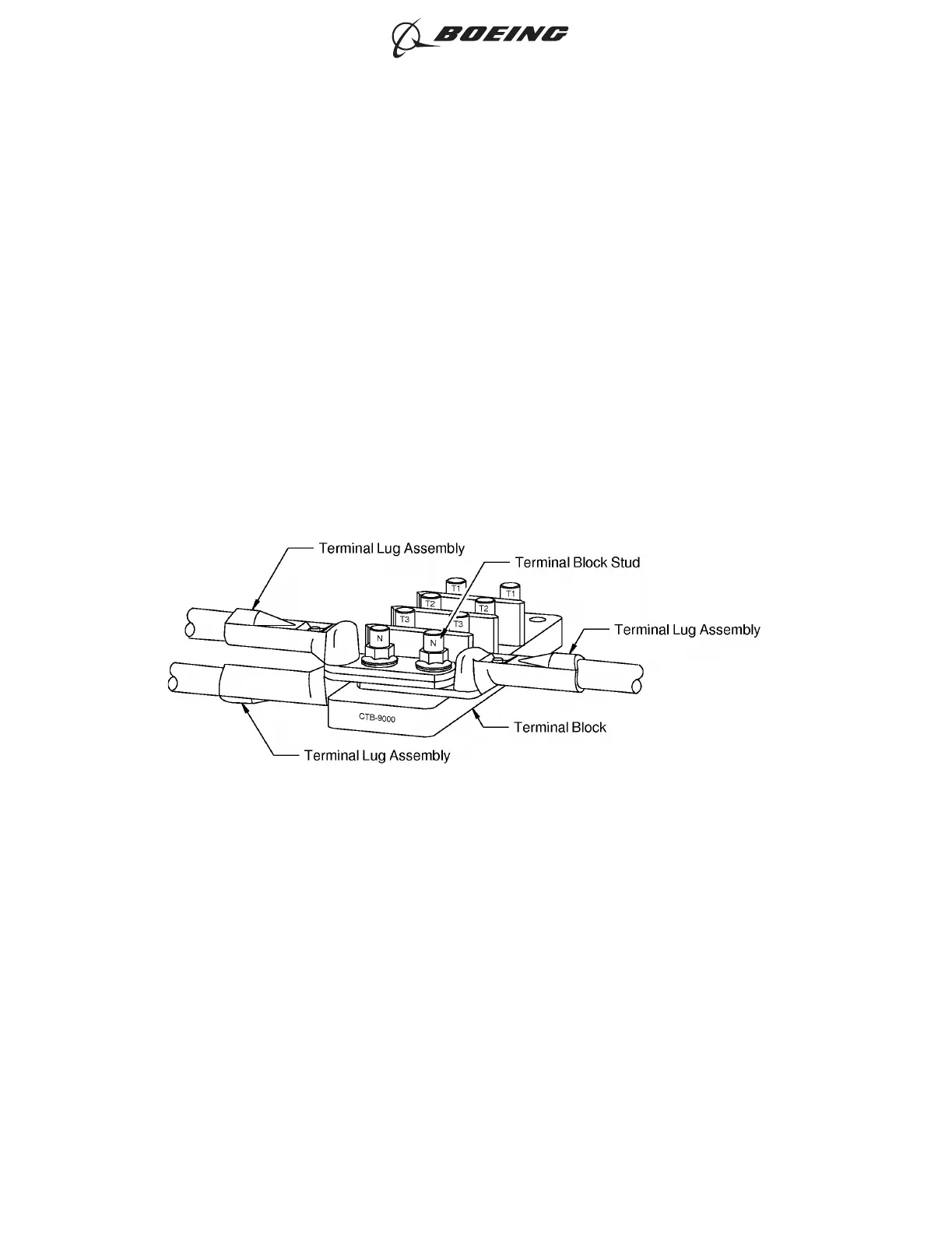

POSITION OF THE TERMINAL LUG ASSEMBLIES ON THE CTB TERMINAL BLOCK

Figure 14

ELECTRICAL CONNECTION OF EQUIPMENT AND INSTALLATION OF TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-00

Page 19

Feb 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...