(6) Crimp the terminal lug.

Make sure that:

• All of the strands of the conductor are in the crimp barrel

• The end of the conductor extends farther than the end of the crimp barrel

• If the terminal lug has an insulation grip, the end of the wire insulation is in the insulation

grip of the terminal lug

• If the terminal lug has an insulation grip, the crimp tool is adjusted to give the correct

insulation support. Refer to Paragraph 2.B.

• If the terminal lug does not have an insulation grip, the maximum distance from the end of

the wire insulation of a single wire to the end of the crimp barrel is 0.12 inch for AWG 10 and

smaller, and 0.25 inch for AWG 8 and larger

• The clearance from the end of the conductor is sufficent for the installation of the washer

and the nut.

E. Assembly of BACT12AL Terminal Lugs

Refer to Paragraph 1.C. for the description of the BACT12AL terminal lugs.

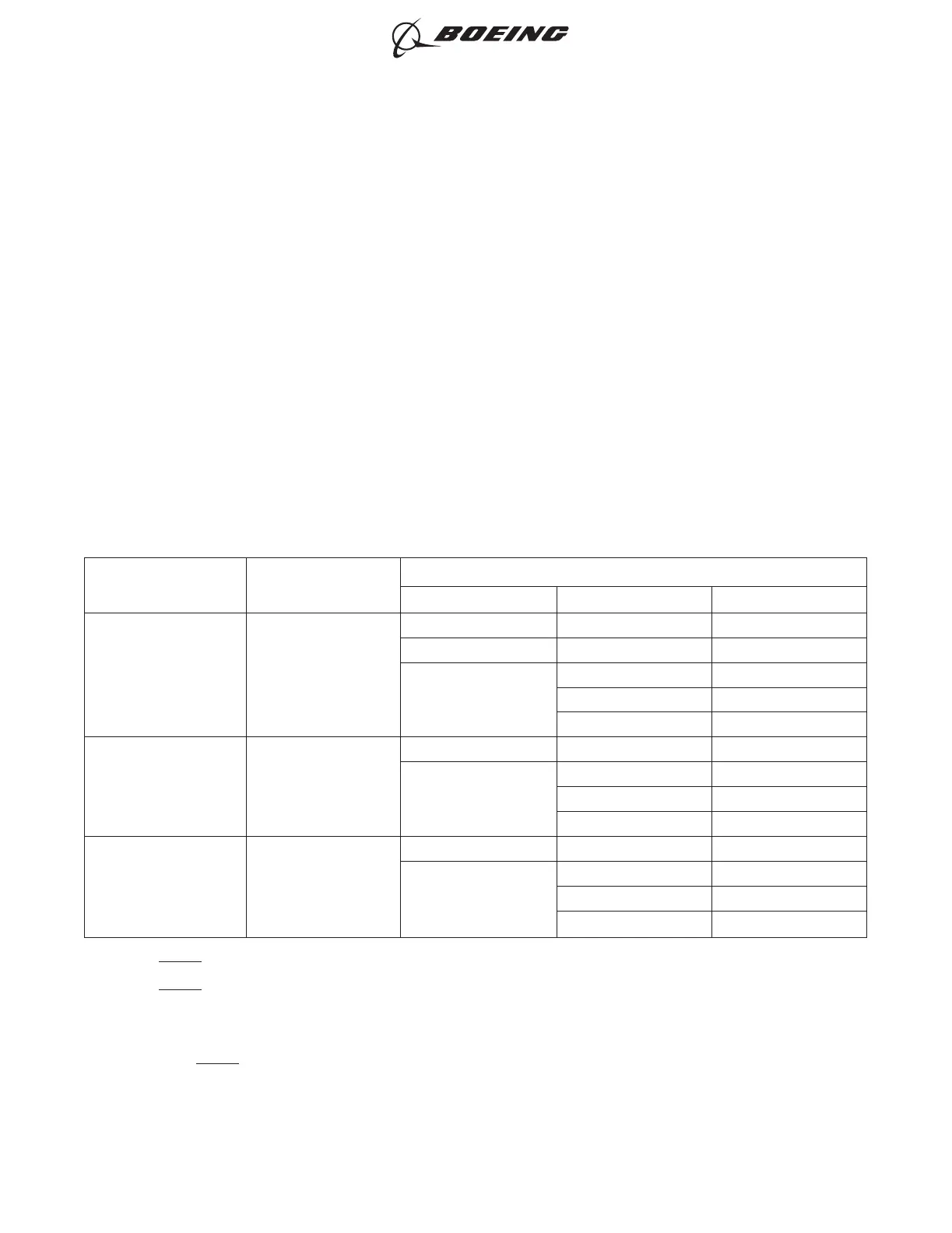

Table 55

CRIMP TOOLS FOR BACT12AL TERMINAL LUGS

Crimp Barrel Size Insulation Color

Crimp Tool

Basic Unit Head Die Set

8 Red

59974-1 - 47820

69010 68285-1 -

Power Pump

69051 47820

69061 47820

ST970-12 47820

6 Blue

59974-1 - 47821

Power Pump

69051 47821

69061 47821

ST970-12 47821

4 Yellow

59974-1 - 47822

Power Pump

69051 47822

69061 47822

ST970-12 47822

NOTE: Refer to Table 40 for the part numbers of the recommended Power Pumps.

NOTE: Refer to Subject 20-30-22 for the assembly of a terminal lug with a conductor that is smaller

than the crimp barrel size of the terminal lug.

(1) Make a selection of a terminal lug from Table 5.

NOTE: For the selection of the terminal, use:

• The crimp barrel size, if one wire is to be terminated

ASSEMBLY OF INSULATED AND UNINSULATED TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-11

Page 60

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...