4. ASSEMBLY OF COPALUM SPLICES

A. Necessary Materials

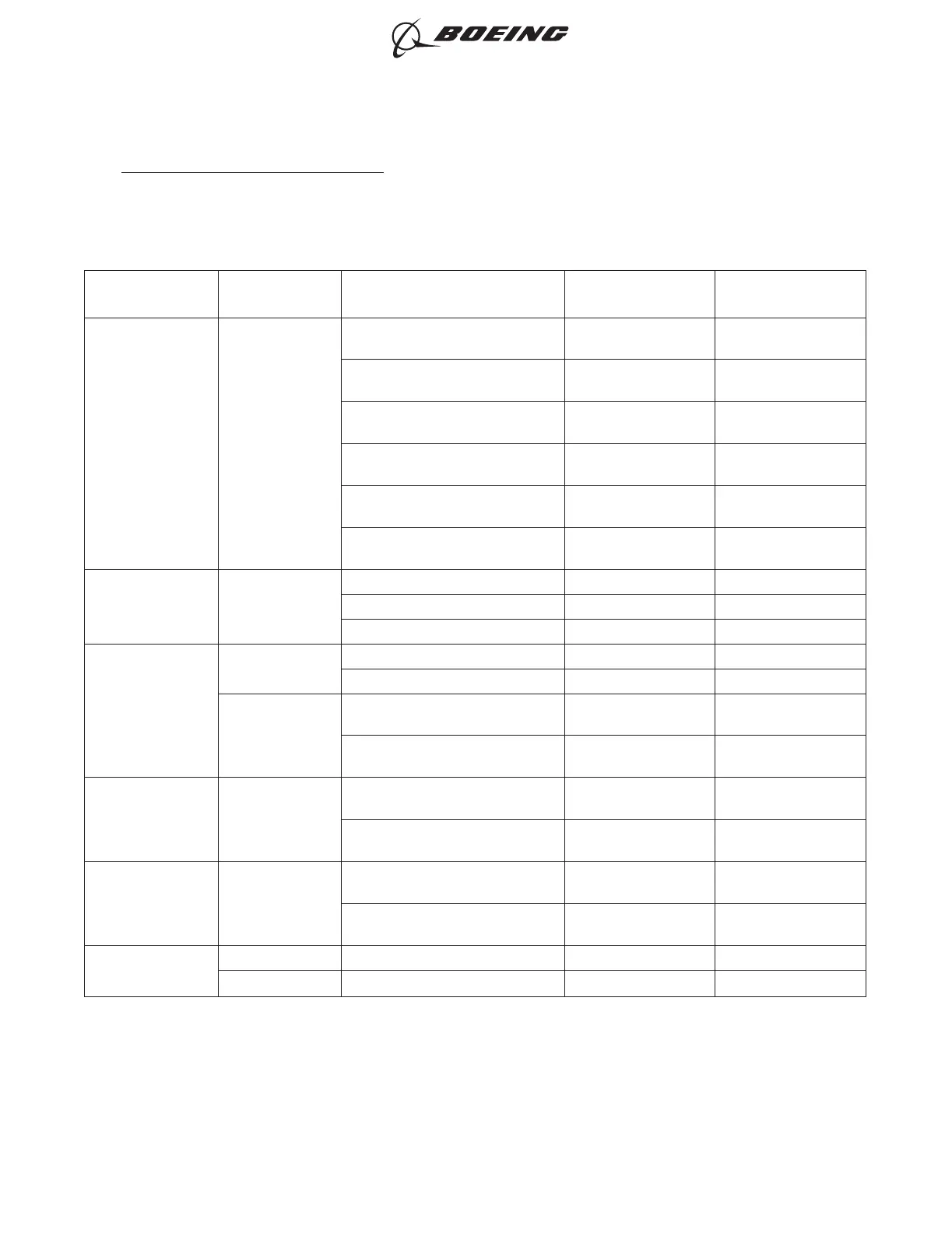

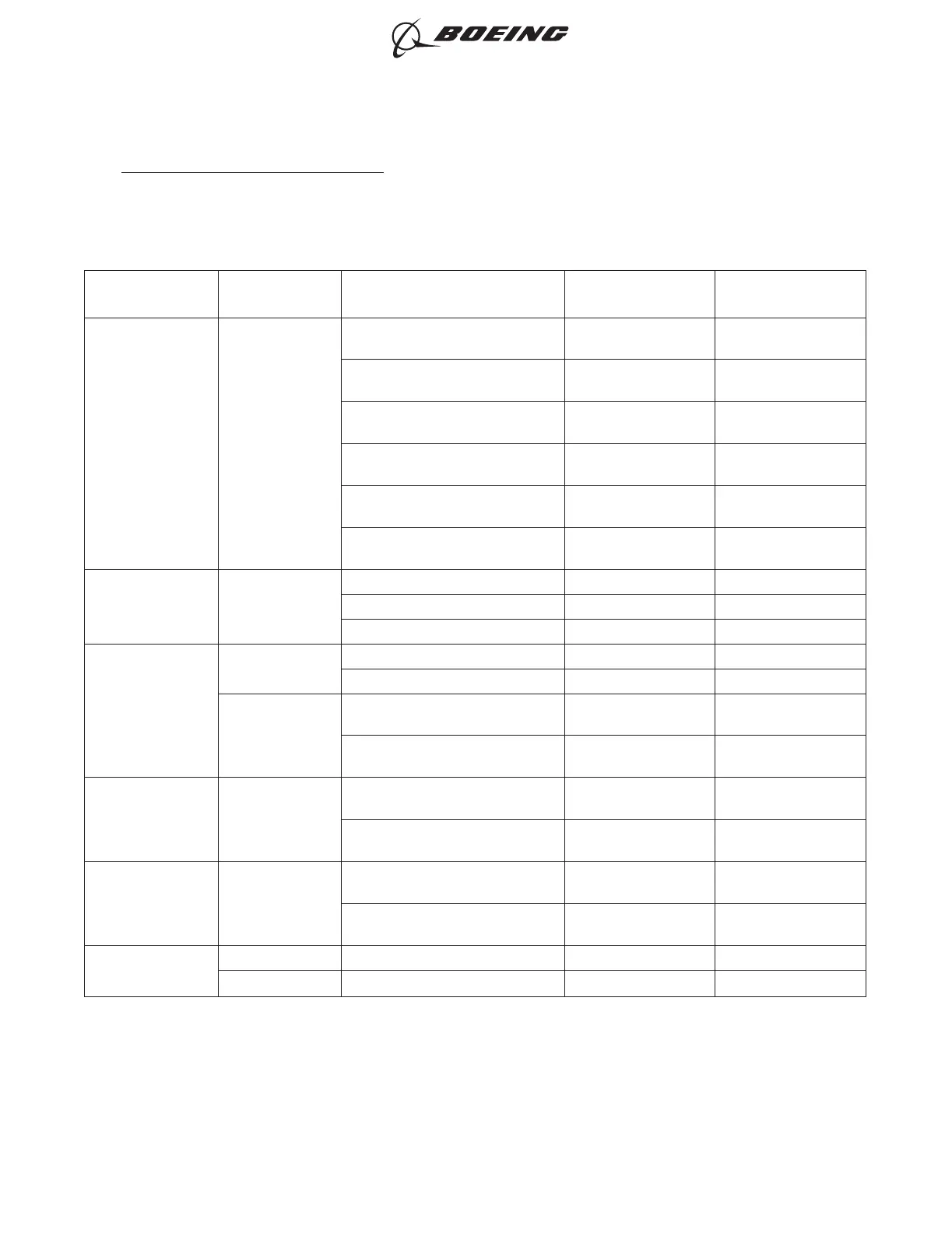

Table 7

NECESSARY MATERIALS

Material

Temperature

Grade

Part Number Description Supplier

Release Agent -

MS-122AD -

Miller-Stephenson

Chemical

MS-122DF -

Miller-Stephenson

Chemical

MS-122N/CO2 -

Miller-Stephenson

Chemical

MS-122SD -

Miller-Stephenson

Chemical

MS-122V -

Miller-Stephenson

Chemical

MS-122XD -

Miller-Stephenson

Chemical

Solvent -

TT-I-735, Grade A or Grade B Isopropyl Alcohol An available source

TT-N-95, Type II Aliphatic Naptha An available source

TT-T-266 Lacquer Thinner An available source

Sleeve, Heat

Shrinkable

C

AMS-DTL-23053/10 Silicone QPL

RT-1140 Silicone Raychem

D

AMS-DTL-23053/12, Class 2

TFE, Standard Wall

Thickness

QPL

AMS-DTL-23053/12, Class 3

TFE, Thin Wall

Thickness

QPL

Tape, Insulation D

Scotch 70

Silicone, Self-Bonding,

1 inch width

3M

A-A-59163, Type 1

Silicone, Self-Bonding,

1 inch width

QPL

Tape, PTFE D

P-421

PTFE, Silcone

Adhesive, 1 inch width

Permacel

SG26-03

PTFE, Silcone

Adhesive, 1 inch width

Saint-Gobain

Performance Plastics

Wiper

- BMS15-5 Class A - A qualified source

- BMS15-5 Class B - A qualified source

ASSEMBLY AND REPAIR OF THE AMP AND BACS52N COPALUM SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-13

Page 9

Oct 15/2015D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...