Table 31

CONNECTIONS

Wire Connection Wire conneted to

A Splice B and C

(1) Remove approximately 0.05 inch from each end of the shield material with a pair of scissors or an

equivalent tool.

NOTE: The shield material has fused ends that hold the ends of the strands of the shield

together.

(2) Put these splice assembly components on Cable A in this sequence:

• The outer sleeve

• A solder sleeve

• The shield material

Make sure that the small end of the solder sleeve is put on the cable first.

(3) Put the other solder sleeve on Cable B and Cable C.

Make sure that the small end of the solder sleeve is put on the cables first.

(4) Put a seal sleeve on Wire A.

B. Kit Group T1( ) 1, T2( ) 1, T3( ) 1 or T4( ) 1 - One Class 1 Cable to One Class 1 Cable

For the conditions that are applicable for this procedure, refer to Paragraph 2.B..

Refer to Figure 30.

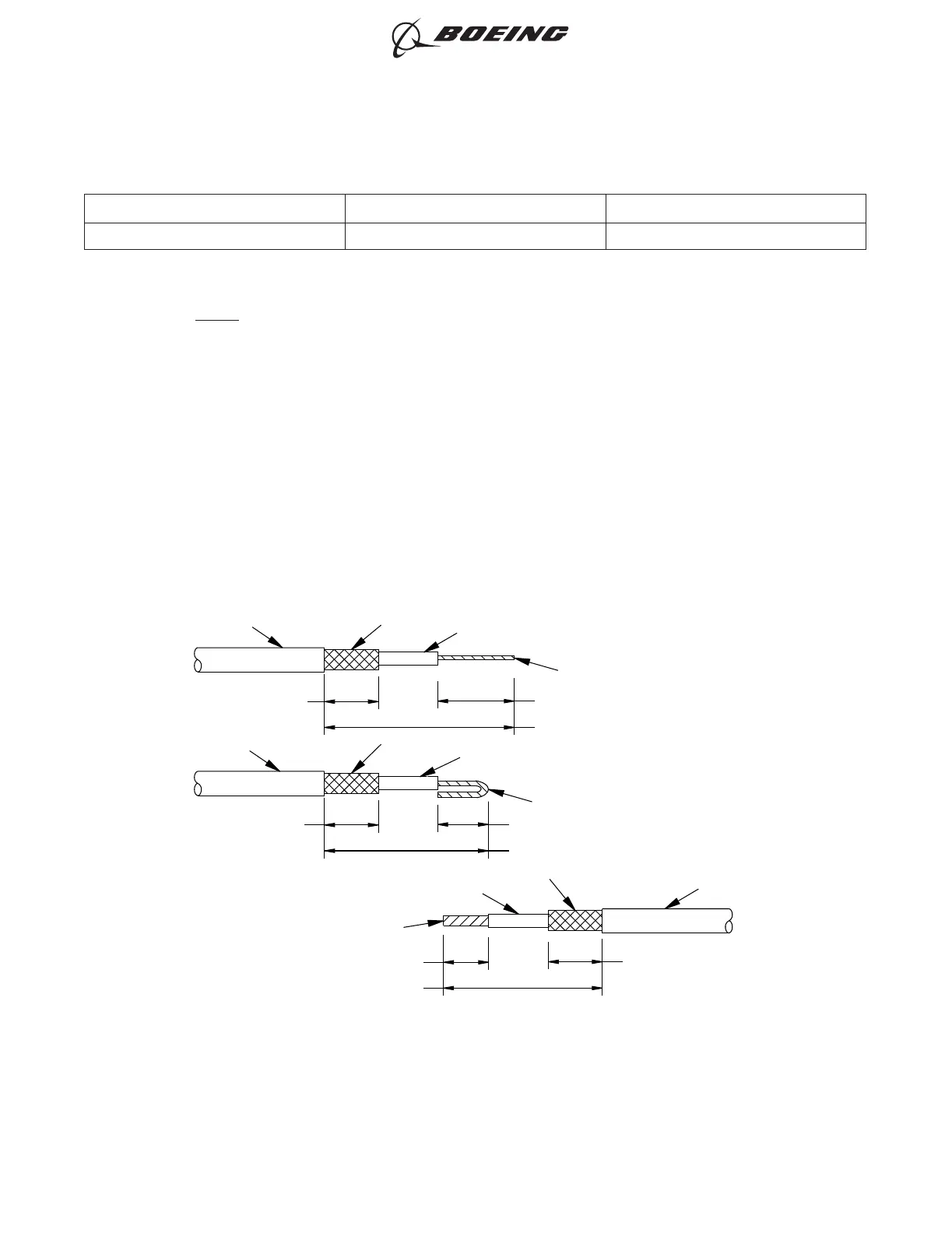

CONDUCTOR

INSULATION

SHIELD

1.07 ±0.02 INCHES

0.37 ±0.02 INCH

CABLE B

JACKET

0.27 ±0.02 INCH

INSULATION

SHIELD

CABLE A

CABLE A

CONDUCTOR

1.07 ±0.02 INCHES

0.27 ±0.02 INCH

0.37 ±0.02 INCH

JACKET

INSULATION

SHIELD

CONDUCTOR

JACKET

0.37 ±0.02 INCH

1.37 ±0.02 INCHES

0.57 ±0.02 INCH

2449847 S00061545800_V2

ONE CLASS 1 CABLE TO ONE CLASS 1 CABLE

Figure 30

ASSEMBLY OF BACS52T SERIES SHIELDED SPLICE ASSEMBLIES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-21

Page 77

Feb 15/2022D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...