(e) Crimp the splice.

(8) Do Step 7.E.(7) again to assemble the other end side of the butt splice.

(9) Put three layers of insulation tape on the splice assembly.

(a) Tightly wind the first layer of tape on the splice assembly.

Make sure that the layer:

• Starts at the rear end of the layers of tape on the two wires on one end of the splice

assembly

• Stops at the rear end of the layers of tape on the two wires on the other end of the

splice assembly

• Makes a 50 percent overlap.

(b) Tightly wind the second layer of tape on the splice assembly in the opposite direction of the

first layer.

Make sure that the layer:

• Starts 1 inch minimum farther than where the first layer stops

• Stops 1 inch minimum farther than where the first layer starts

• Makes a 50 percent overlap.

(c) Tightly wind the third layer of tape on the splice assembly in the opposite direction of the

second layer.

Make sure that the layer:

• Starts where the second layer stops

• Stops where the second layer starts

• Makes a 50 percent overlap.

(10) Assemble a lacing tape wire harness tie on each end of the splice assembly approximately 0.25

inch from the end of the tape. Refer to Subject 20-10-11.

Make sure that the Temperature Grade of the lacing tape is Temperature Grade B or higher.

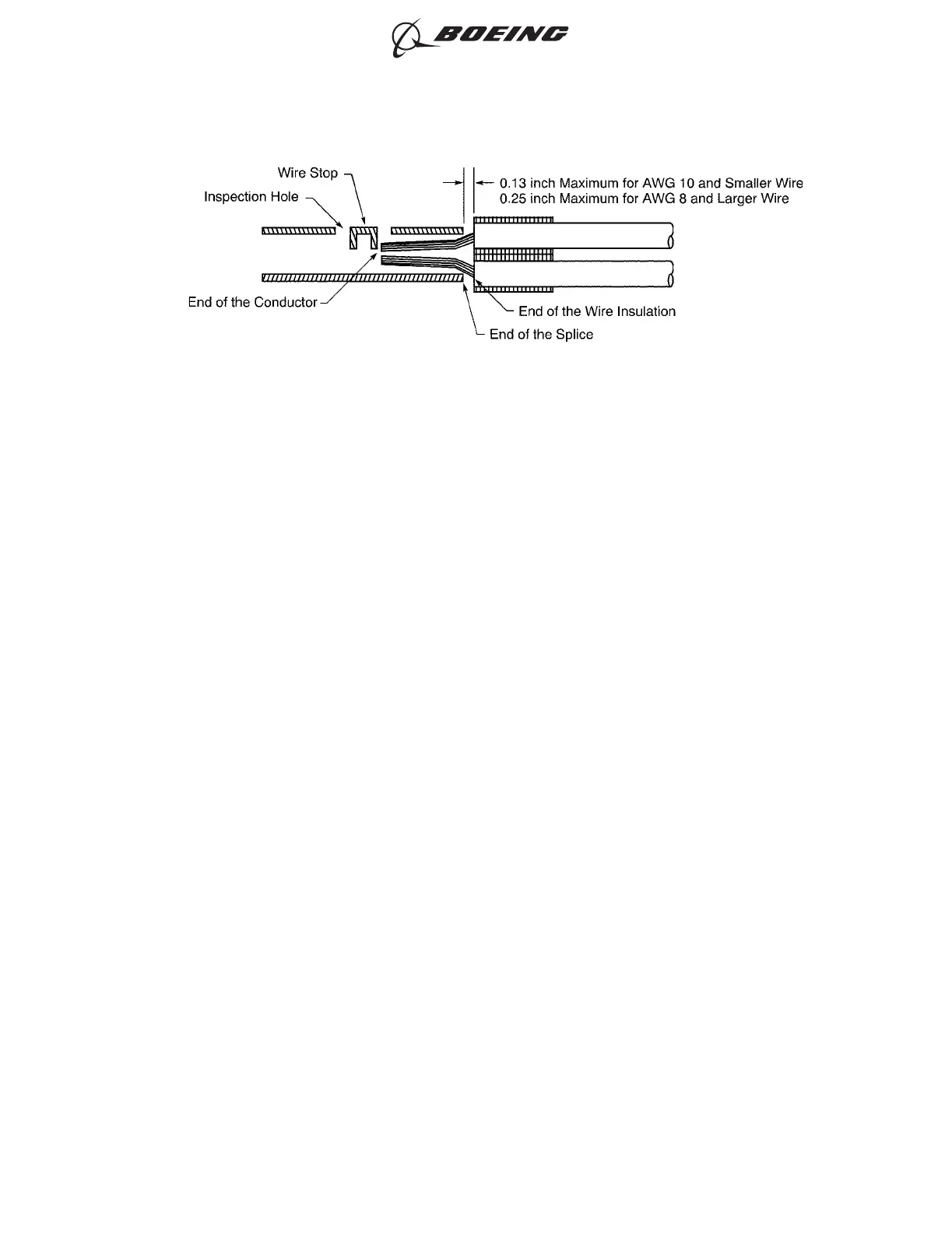

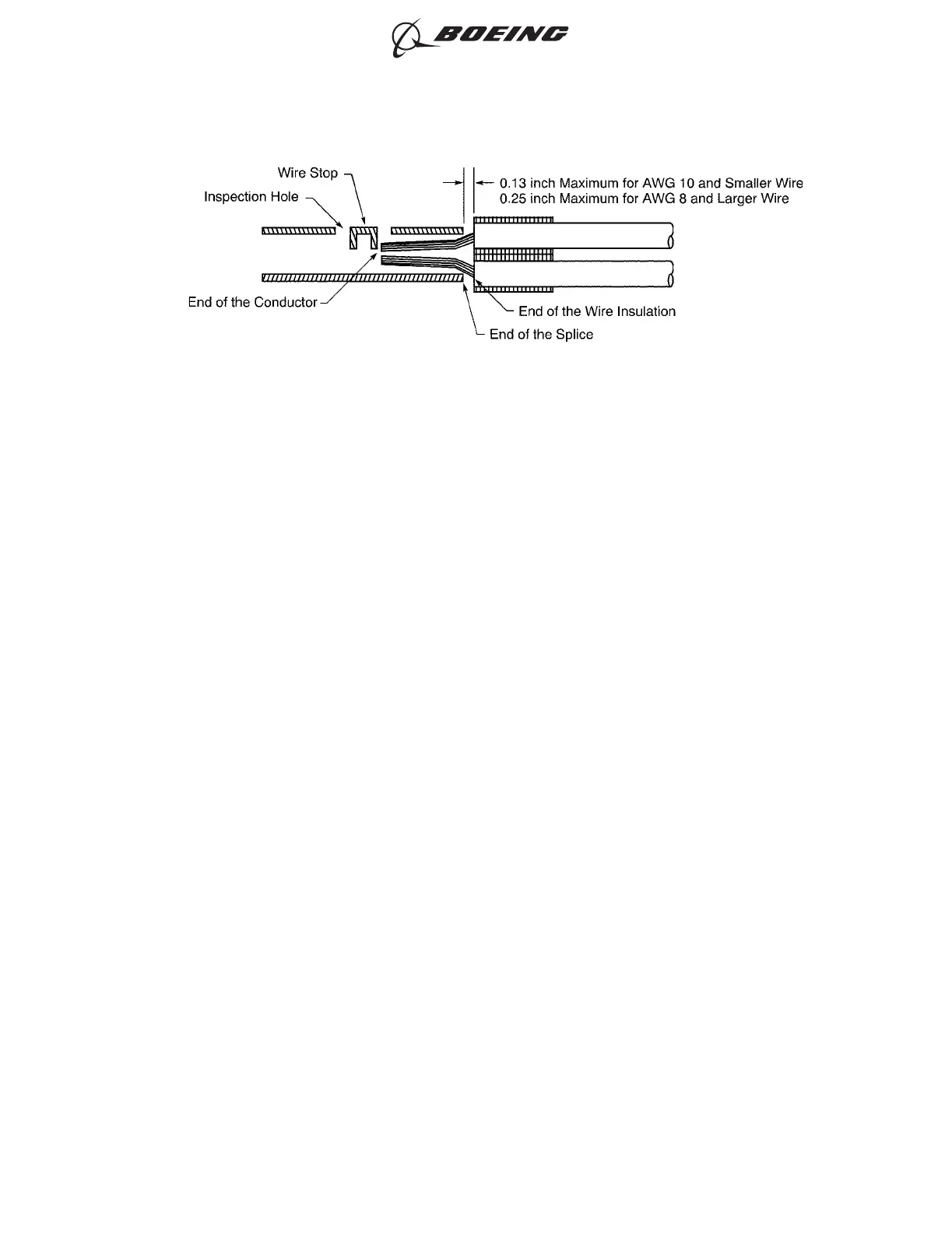

POSITION OF THE WIRES IN THE BUTT SPLICE

Figure 56

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 95

Feb 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...