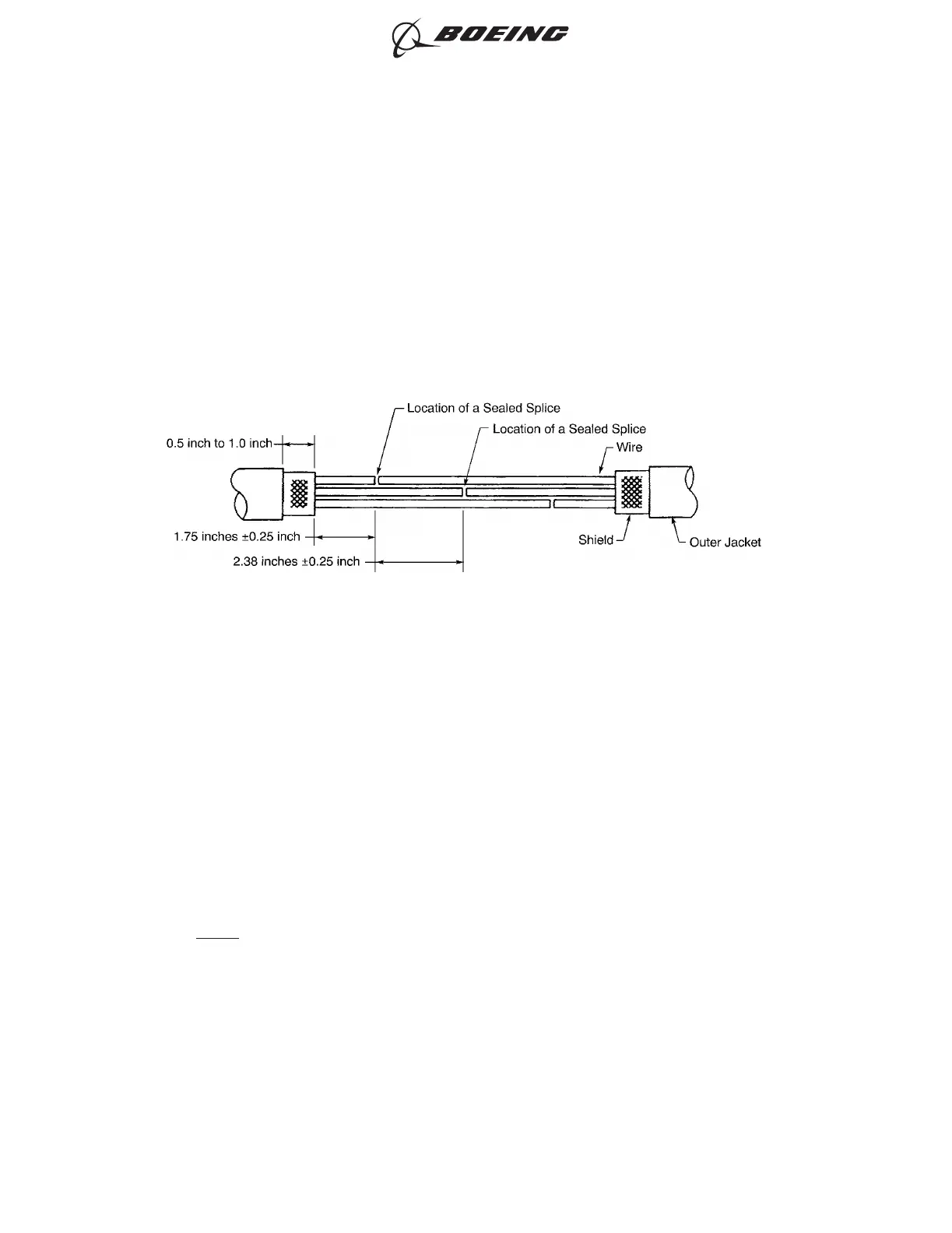

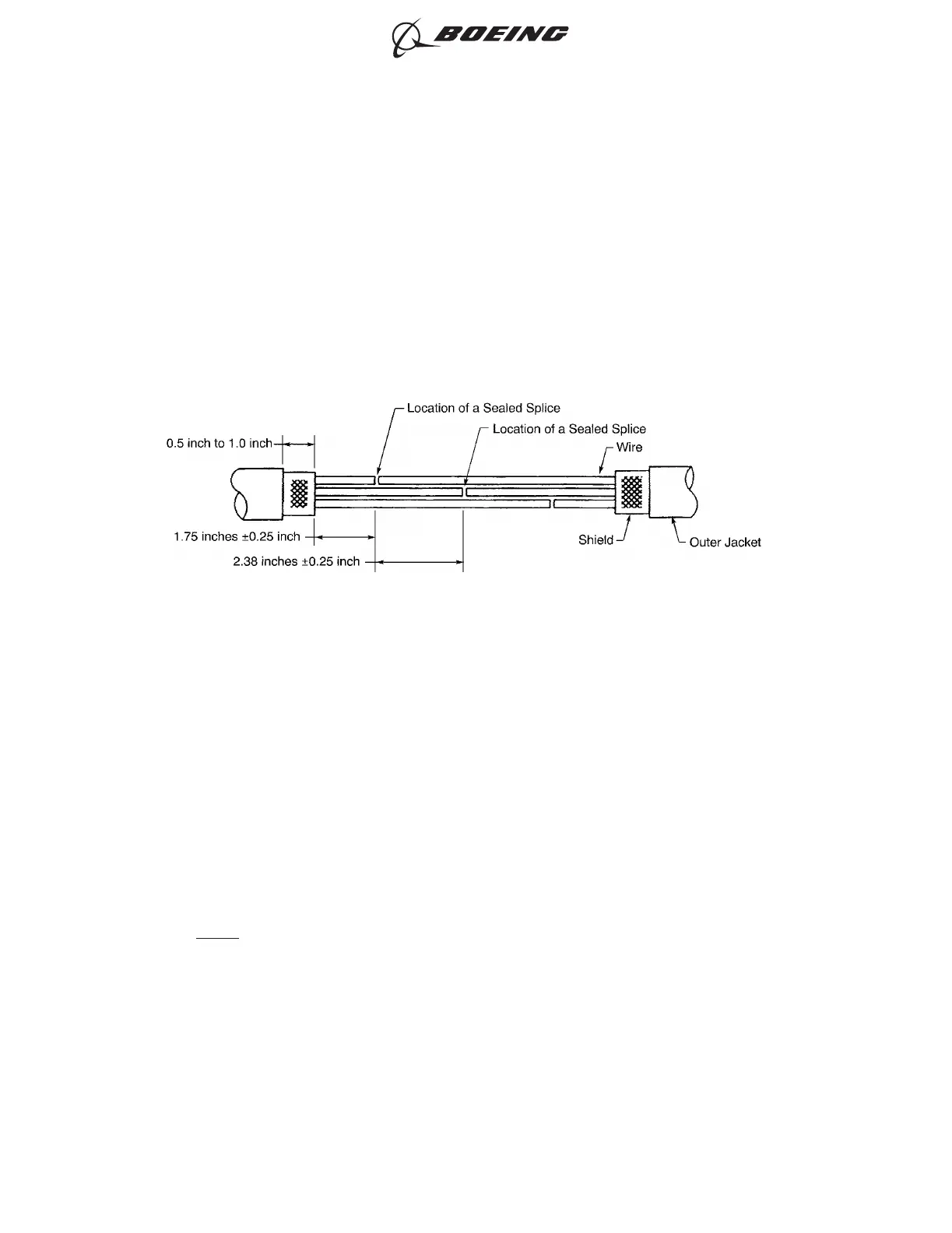

Make sure that:

• The distance from the end of the outer jacket to the end of the shield is 0.5 inch to 1.0 inch

• The distance from the end of the shield to the center of the nearest sealed splice is 1.75

inches ±0.25 inch

• The distance from the center of a sealed splice on one wire to the center of the nearest

sealed splice on another wire is 2.38 inches ±0.25 inch.

(4) Fold the end of the shield against the outer jacket.

(5) Put a temporary layer of tape around the end of each shield to make sure that the shields do not

move.

(6) Cut the necessary length of the shield sleeve material.

Make sure that the ends of the shield sleeve material extend farther than the rear end of the

Shield-Kons on each end of the shield splice.

(7) Put the shield sleeve material on the end of the other cable.

NOTE: If it is necessary, the strands at the end of the shield sleeve material can be moved apart

to make it easier to put the shield sleeve material on the cable.

(8) Make a selection of an applicable Temperature Grade B conductor splice configuration for one

wire to one wire. Refer to Paragraph 9.A.

(9) Assemble the conductor splice. Refer to the applicable procedure given in Paragraph 9.A.

(10) Align one end of the shield sleeve material with the end of the folded back shield. Refer to Figure

201.

PREPARATION OF THE SHIELDED CABLE

Figure 200

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 242

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...