(2) Twist the end of the shield material until it is tight against the shield of the cable.

(3) For a cable where the shield is not folded back, install a solder sleeve at the end of the shield

material.

Refer to:

• Figure 4

• Subject 20-10-15 for the procedure to install a solder sleeve without an integral wire.

Make sure that:

• The rear edge of the solder ring is approximately 0.1 inch from the end of the cable jacket

• The rear seal ring does not make an overlap with the shield

• The heat is applied at the end of the solder sleeve that is on the shield material first

• The heat applied at the other end of the solder sleeve to melt it around the cable jacket

• The heat applied at the center of the solder sleeve and the cable is turned in the reflector

until the solder melts.

NOTE: A change of the color of the sleeve is permitted if the solder joint can be seen.

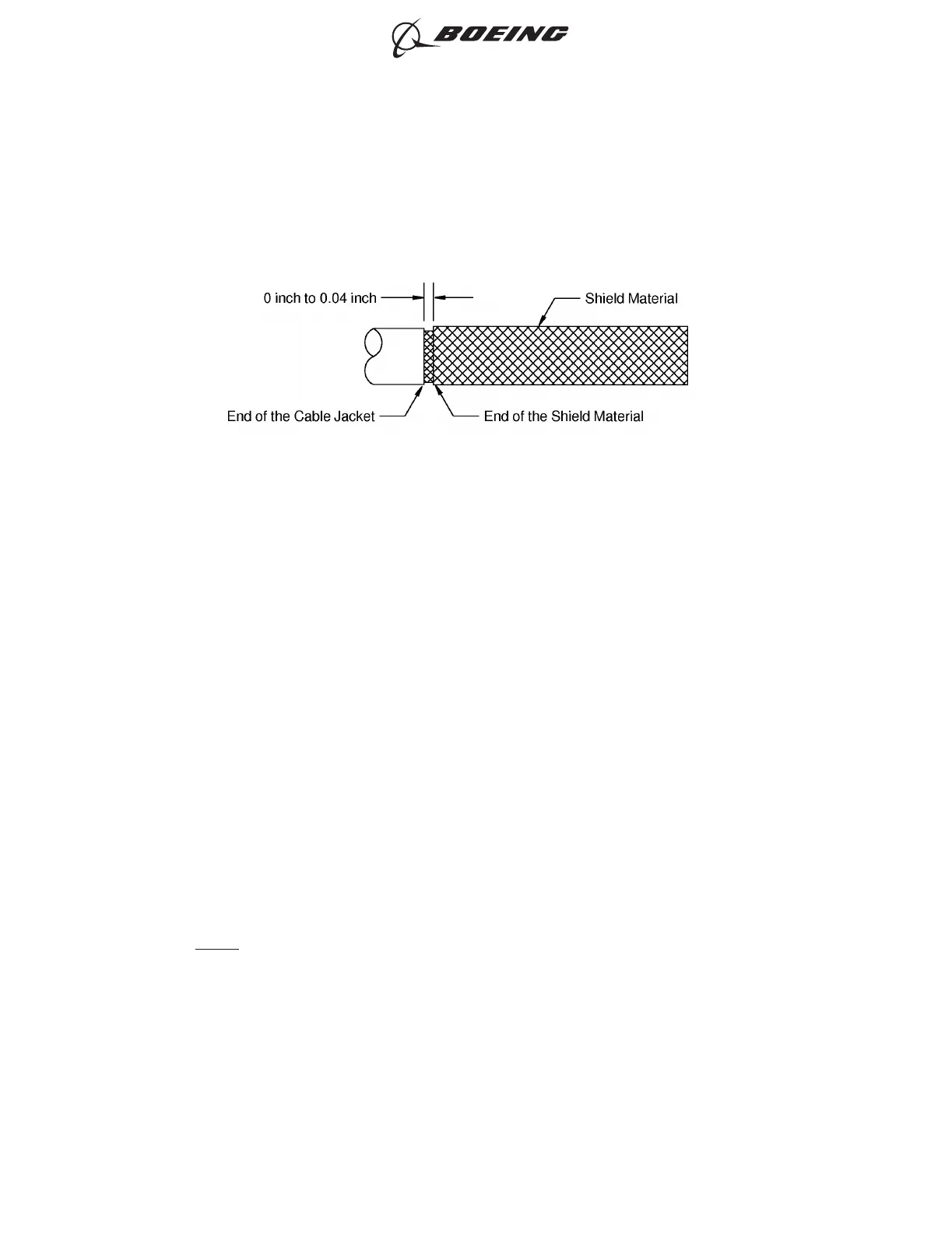

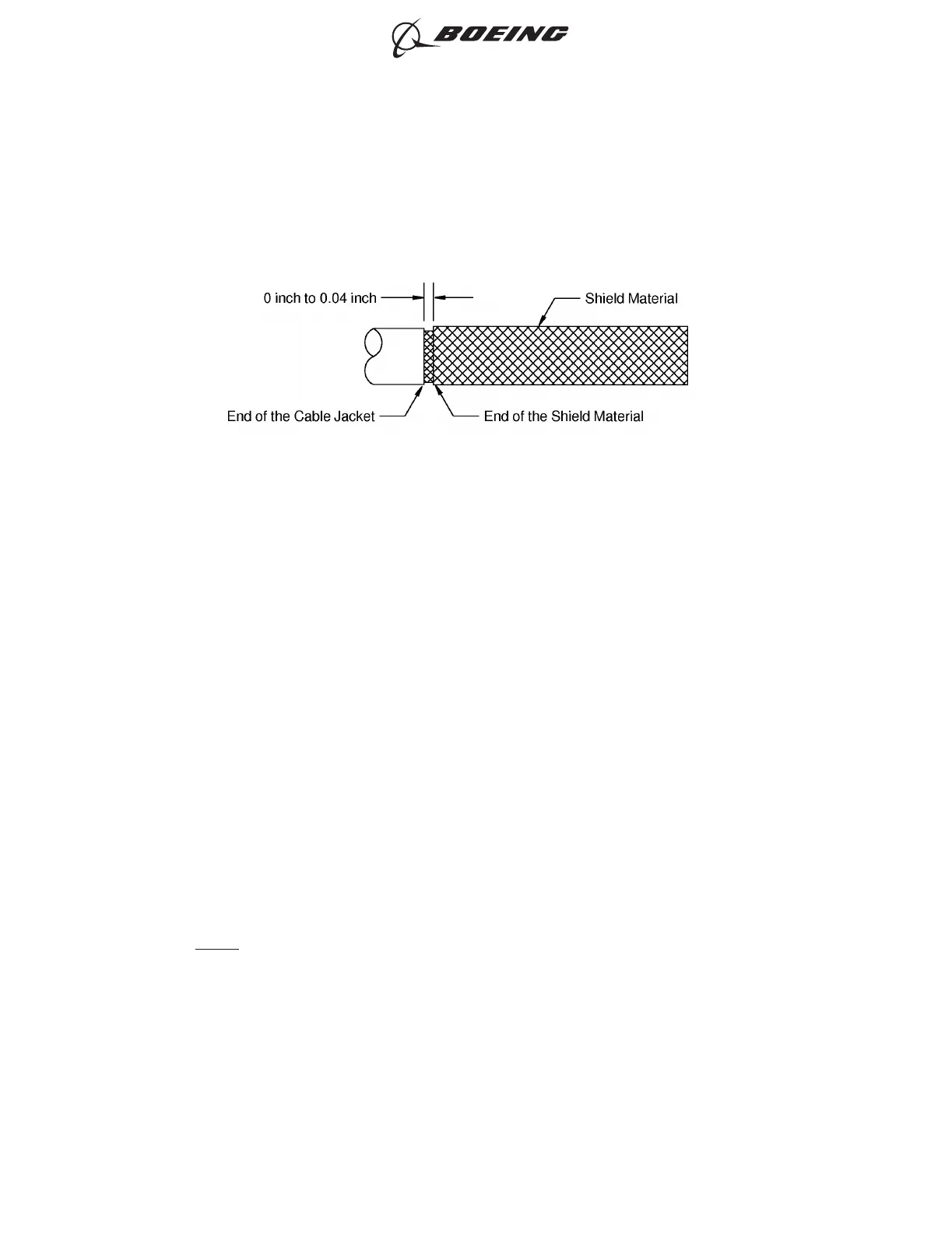

POSITION OF THE SHIELD MATERIAL AT THE END OF THE CABLE JACKET

Figure 3

ASSEMBLY OF BACS52P SERIES AND D-150-0300 SERIES SHIELDED SPLICE ASSEMBLIES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-20

Page 71

Jun 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...