Reaching Contract Speed (System 12 SCR Drive)

4-9

4

iControl DC

Speed Pick Delay (System 12 SCR Drive)

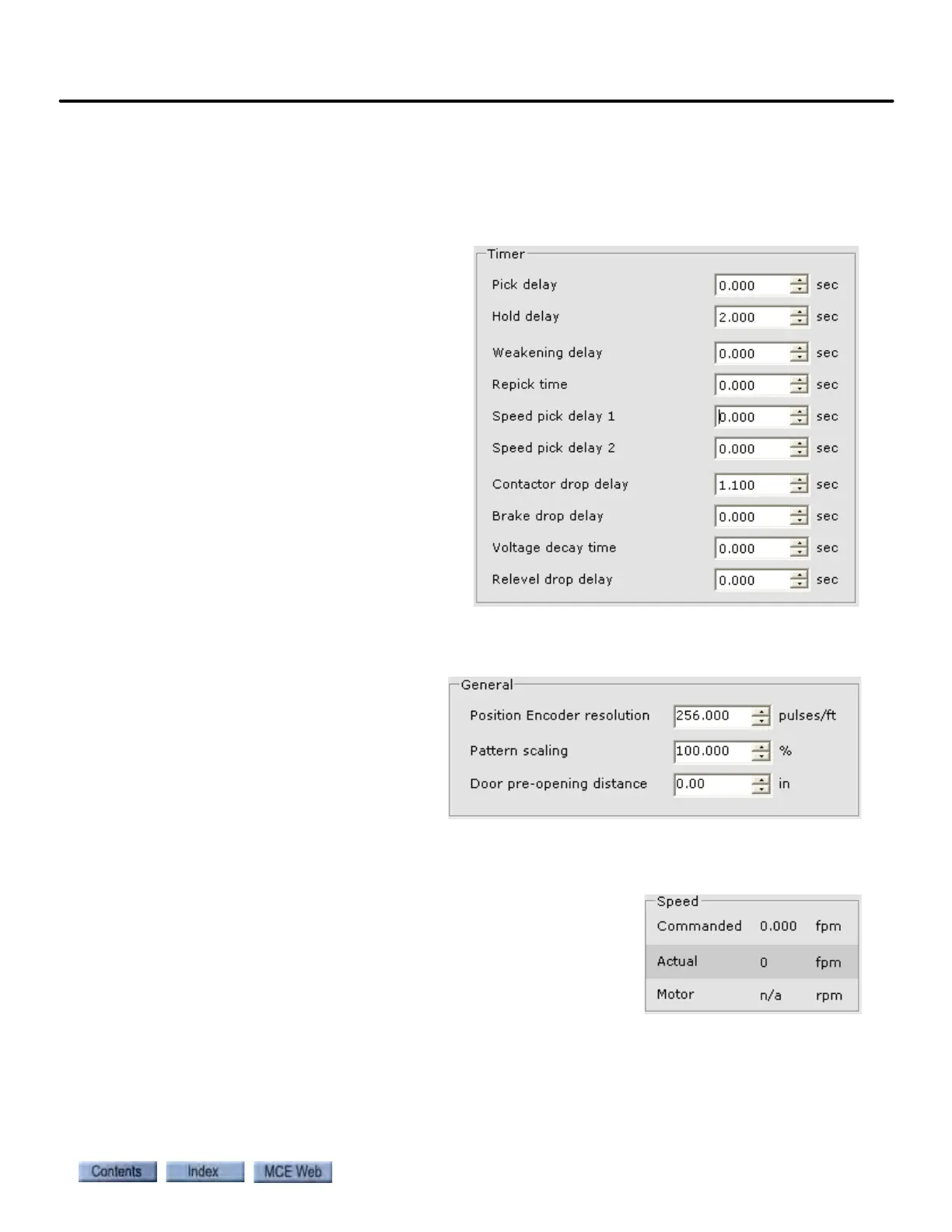

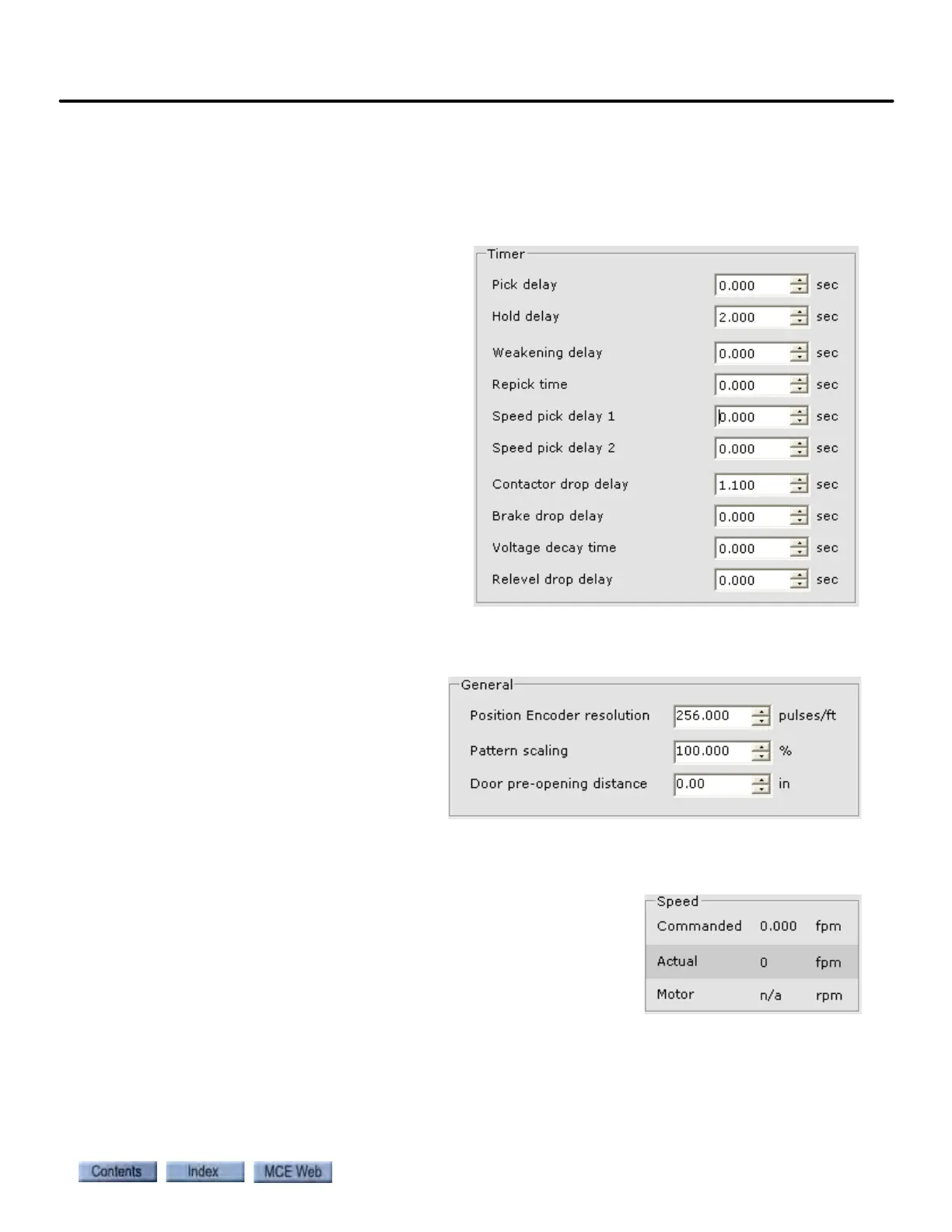

To achieve proper starting, without rollback or snapping away from the floor, a variable delay in

the application of the pattern signal is provided. Speed pick delay 1, on the Configuration >

Brake > Control tab, determines the amount of delay from the time the drive processor activates

the Run Enable signal to the time the pattern generator sends out the pattern signal.

1. First adjust (Brake) Pick delay so

the brake just clears the brake

drum as the car is beginning to

accelerate. Do this with an empty

car. The correct setting can be

determined by watching the drive

sheave. Some rollback may be tol-

erated for now, but will be cor-

rected later. If the Drive On Fault

(DRO) appears on the iBox LCD

display when direction is picked,

first increase Pick delay and then

increase Speed pick delay 1 to

coordinate the application of the

pattern signal with the picking of

the brake.

Pattern Scaling (System 12 SCR Drive)

1. Using Pattern scaling on the

Configuration > Pattern >

Common tab, increase con-

tract speed in 10% increments

until the car is running at

80% of contract speed. Moni-

tor performance on the iView

Virtual Oscilloscope. Set:

• Test point 1 to Pattern Command (8V equals contract speed at 100% scaling)

• Test point 2 to Speed Feedback (8V equals contract speed at 100% scaling)

2. Check for severe overshoot by monitoring Speed/Actual

on the Operational Status tab. Excessive overshoot can

trip the governor. If severe overshoot does not occur, con-

tinue to increase car speed in 10% increments by increas-

ing Pattern scaling incrementally up to a maximum of

100%. Verify that car speed is peaking at no more than 3%

over contract speed (10 fpm @ 350 fpm, 15 fpm @ 500

fpm, etc.).

3. If overshoot occurs, reducing Standard/Low roll jerk (Configuration > Pattern > Modes

tab) may help, however, a Safety A (or B) Contract Overspeed Fault will occur if Stan-

dard/Low roll jerk is reduced too much.

Loading...

Loading...