Construction Mode

2-26 Manual # 42-02-7223

Velocity Encoder Installation and Wiring

(If you are using a tachometer, please see the preceding topic.) The encoder must be mounted

and wired according to the drawings. When installed, the encoder must be electrically isolated

from the motor or any other ground. (Resistance between the encoder casing and the motor or

other ground should be “infinite.”)

Do not mount the encoder or its wiring close to a magnetic field (the motor or brake coils). Mag-

netic fields can induce AC into the encoder signal, producing erratic control at lower speeds.

Encoder wiring must use a separate, grounded conduit. Inside the controller cabinet, if control

wires must cross power wires, they must cross at right angles to reduce the possibility of inter-

ference.

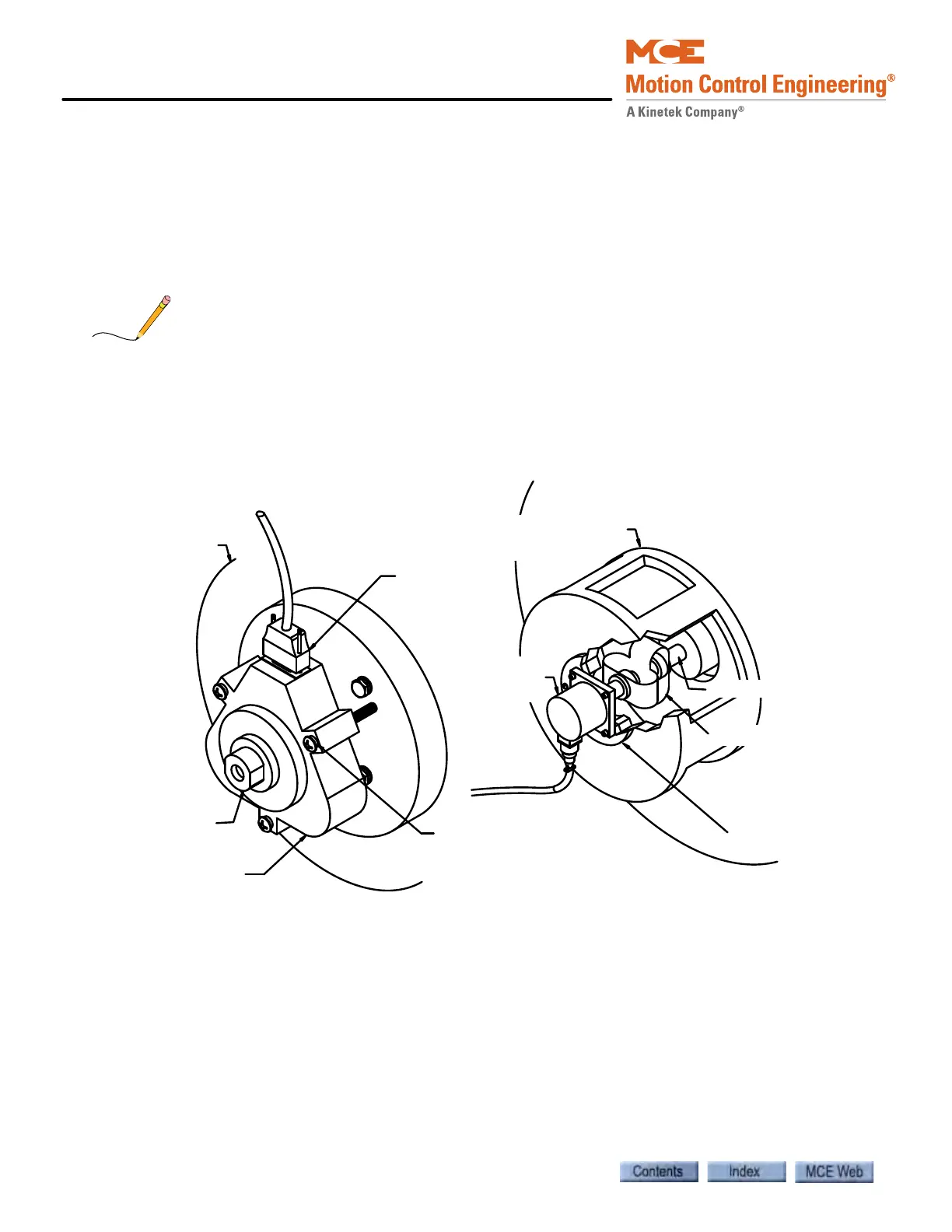

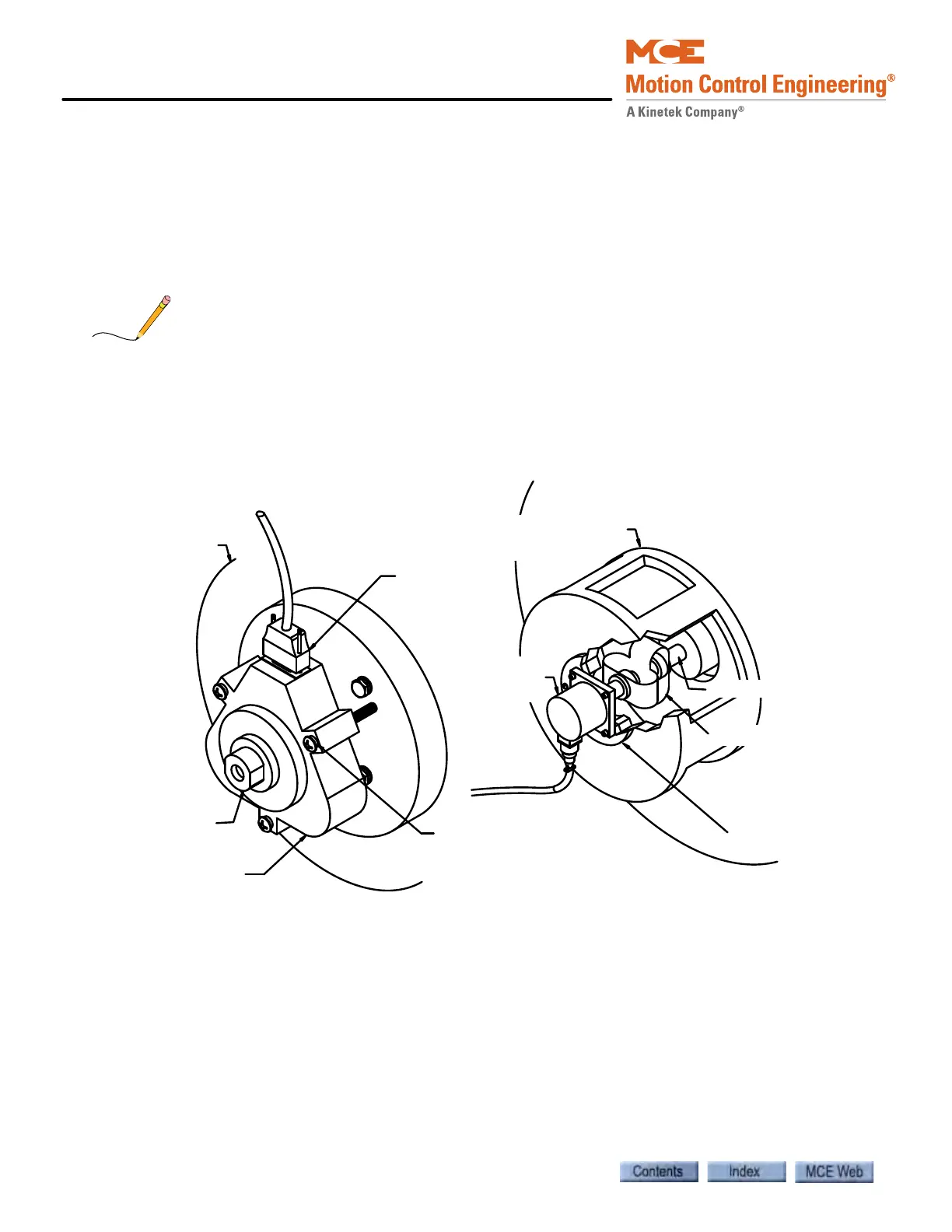

Encoder Mounting The following illustration shows two typical encoder installations.

Figure 2.9 Typical Encoder Installations

It is very important that the encoder does not slip, wobble, bounce, or vibrate due to poor instal-

lation of the shaft extension, coupling, or encoder mounting. It is also important that the

encoder housing be electrically insulated from the motor, machine, or other ground if the

encoder is manufactured by BEI. An insulated encoder mount has been furnished with the BEI

encoder. However, this type of mounting may not be practical for all applications, therefore, the

best method for mounting the encoder and coupling it to the motor must be determined at the

job site.

Hoist motor

9-pin D

Connector

Isolator

bushing

Velocity Encoder

Hoist motor

shaft

Typical mounting

bracket

Velocity

Encoder

Phenolic

isolator

Flexible coupling

Hoist motor shaft

Loading...

Loading...