DC Hoist Motor, Brake, and Encoder/Tachometer

2-23

2

iControl DC

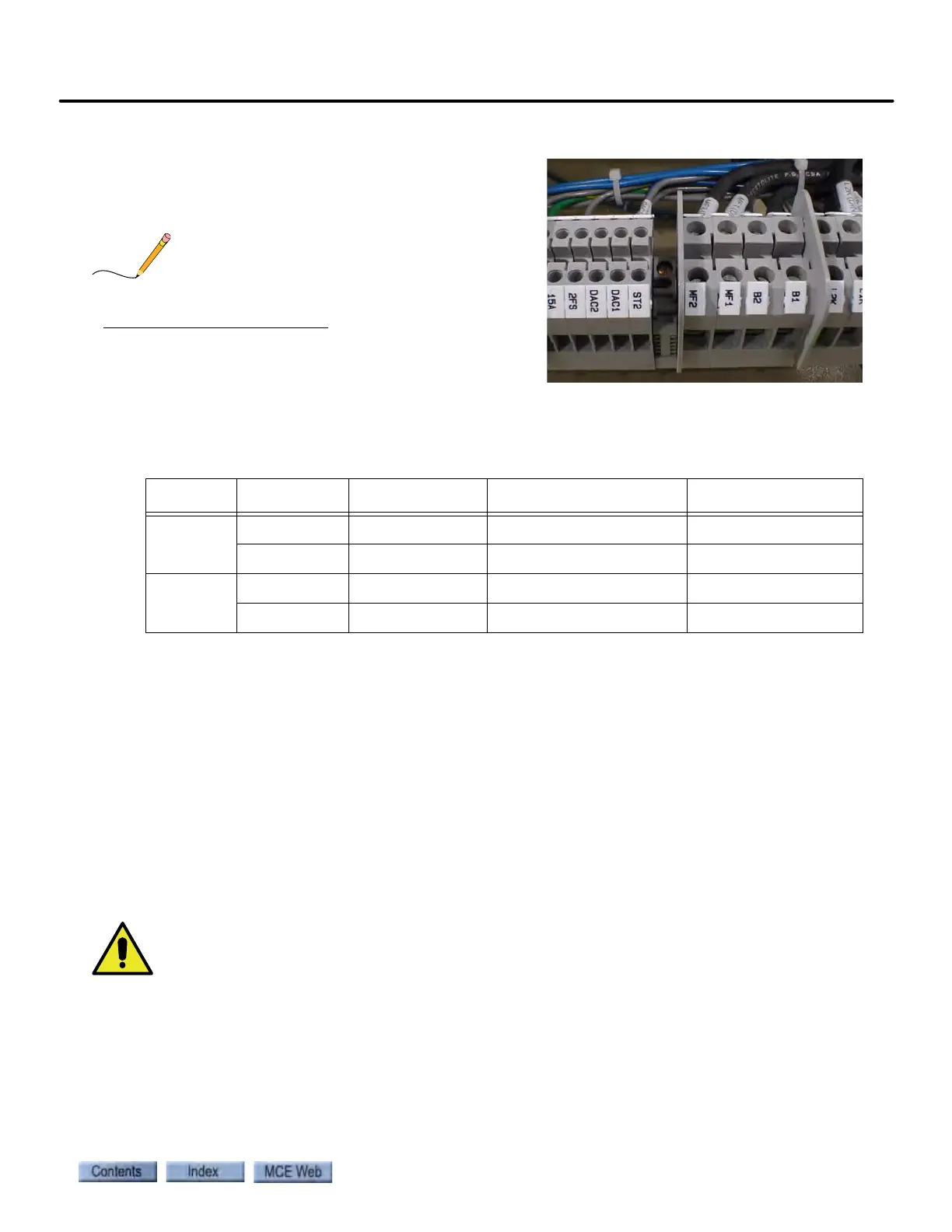

Wiring the Brake

• Refer to job print drawing D2. Connect brake

wires to terminals B1 and B2 located just below

the iPower box.

Brake wires must not be routed in the same conduit

with DC motor wires or velocity encoder wires.

Tachometer or Encoder Installation and Wiring

A tachometer or a velocity encoder may be used.

Tachometer

(If you are using a velocity encoder, please see the next topic.) When installing a tachometer, do

not mount it near a magnetic field (for example, the motor field coils). Magnetic fields may

cause the tachometer to report incorrect speeds. Note also that any vibration caused by the

tachometer cannot be corrected inside the drive. The tachometer wheel and the surface on

which it runs must be smooth and the tachometer must be mounted so that it can maintain con-

tact without binding or bouncing.

Alignment of the tachometer coupling is extremely important. Most vibration problems are

caused by the tachometer or the way in which it was mounted. The tachometer mounting must

be rigid and the tachometer wheel must be aligned precisely with the surface it is running on

(i.e., the brake drum or drive sheave).

In geared applications, do not drive the tachometer from the sheave because gear lash cannot be

compensated by the drive unit.

Table 2.3 Selecting a Tachometer or a Velocity Encoder

Machine Device Shaft Mounting Brake Drum Mounting Sheave Mounting

Geared Tachometer Yes No No

Encoder Yes 1024PPR No No

Gearless Tachometer No Yes Yes

Encoder Yes 12,700PPR Yes 1024PPR Yes 1024PPR

Loading...

Loading...