Final Adjustment

4-24 Manual # 42-02-7223

Motor Control Adjustments (System 12 SCR Drive)

If rollback is a problem and the installation does not use an analog load weigher (allowing Pre-

torque rollback compensation), adjusting Drive > Control tab parameters as described below

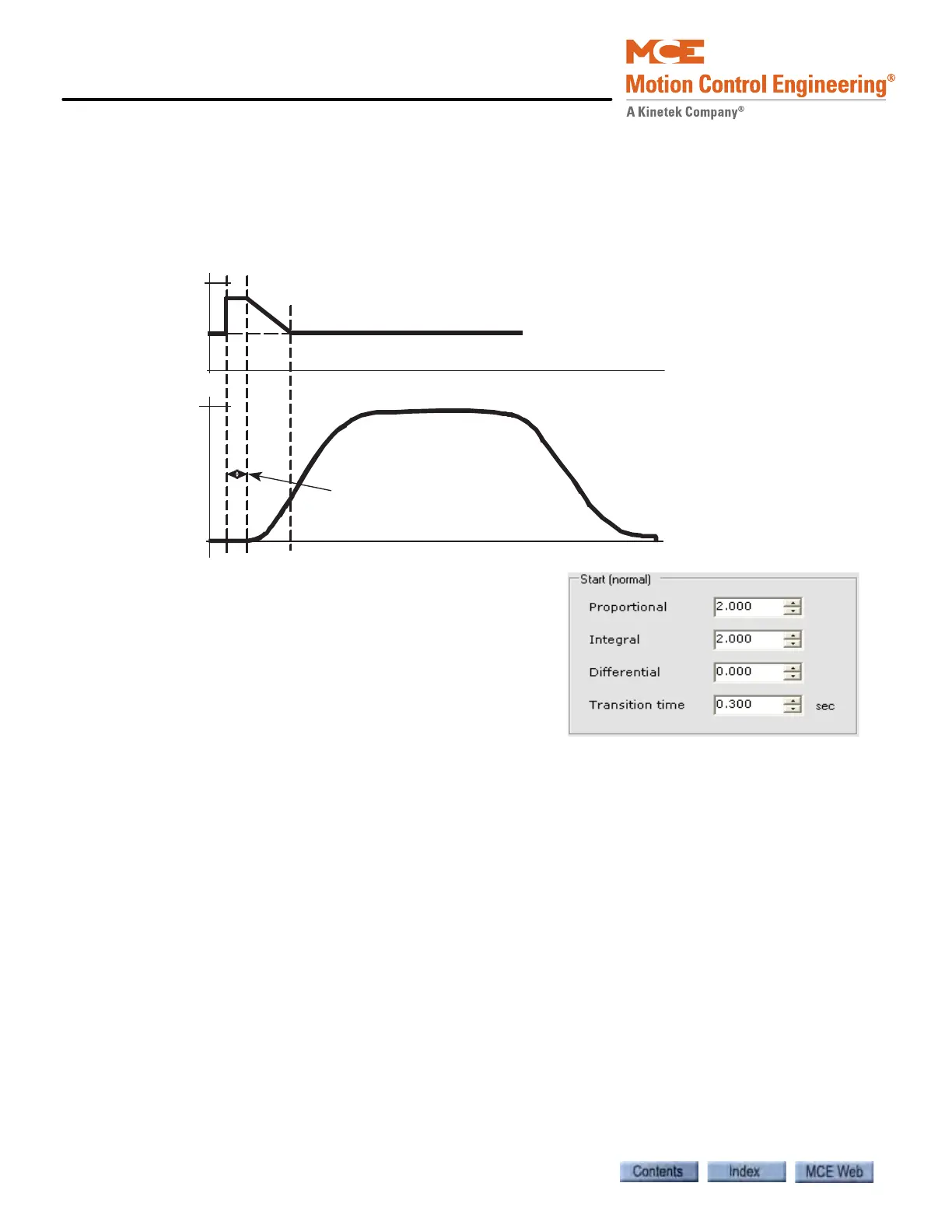

will help. The following illustration shows how normal gains are changed by Start gain (normal)

adjustments.

Figure 4.2 Initial Gain Adjustment Effects

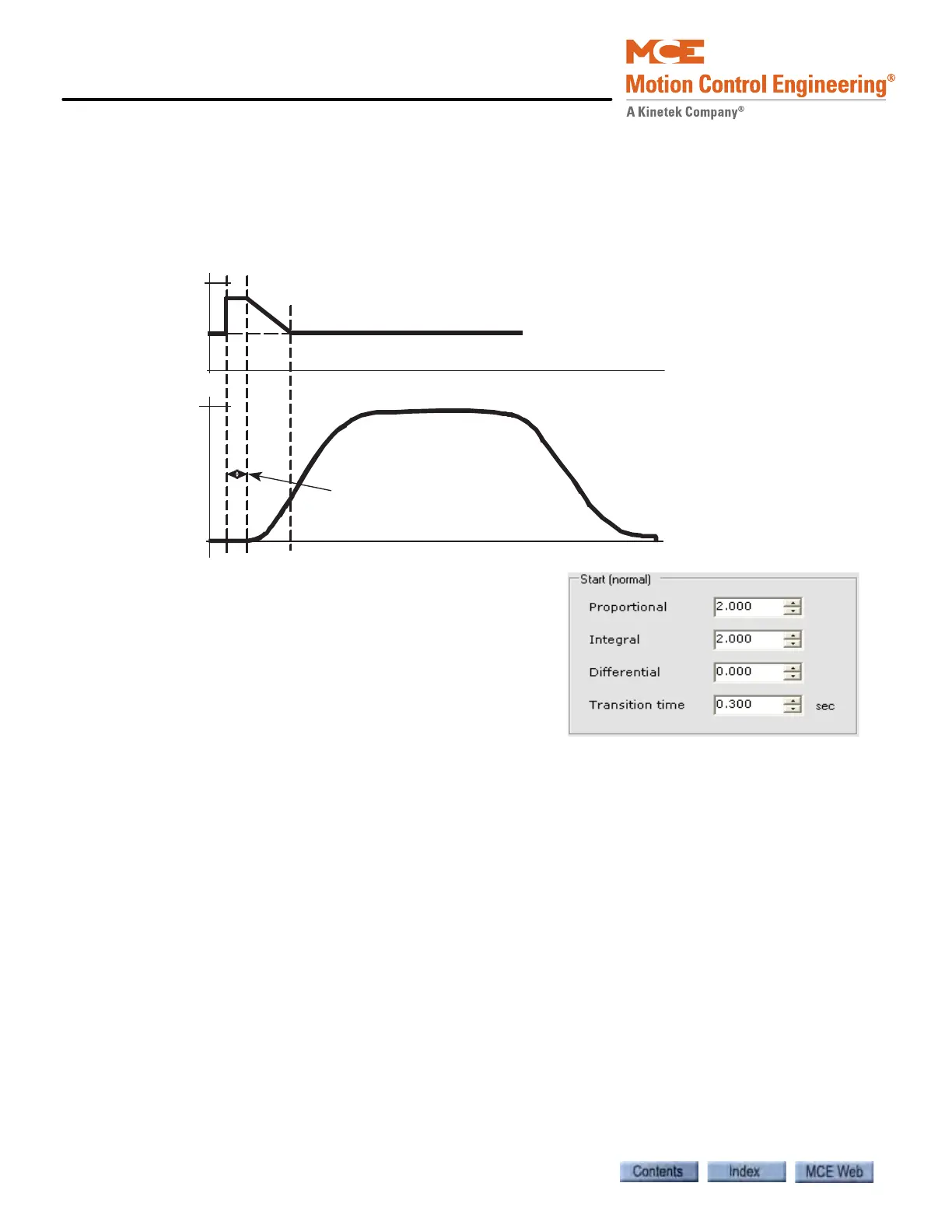

1. On the Drive > Control tab, enable Options /

Start gain (normal).

2. Set PID-Start (normal) / Proportional to twice

the value of PID-Standard / Proportional.

3. Set PID-Start (normal) /Integral to twice the

value of PID-Standard / Integral.

4. Set PID-Start (normal) /Differential to twice

the value of PID-Standard / Differential.

5. Set PID-Start (normal) / Transition Time to 1.0 seconds.

6. Make a one floor run and look for rollback or oscillation at the start of motion.

Rollback

7. If you see rollback, but no oscillation, increase PID-Start (normal) / Proportional, Inte-

gral, and Differential by 25% each.

8. Make a one floor run and again look for rollback or oscillation. If rollback is still a prob-

lem, again increase PID-Start (normal) / Proportional, Integral, and Differential set-

tings by 25% each.

9. Continue testing and adjusting gains as necessary until rollback is controlled but before

oscillation from too much Start (normal) gain becomes a problem.

Oscillation

10. Refer to steps 7, 8, and 9, except begin by reducing Start (normal) / Proportional, Inte-

gral, and Differential by 25%.

11. If oscillation persists, try reducing only the Start (normal) / Differential gain setting.

12. You may also try keeping Proportional and Differential gain as high as possible but

reduce Transition Time in 0.1 second increments until oscillation is diminished but roll-

back remains under control.

Gains

Time

0

5

Pattern

0

10

Normal

Initial

Speed Pick Delay

Loading...

Loading...