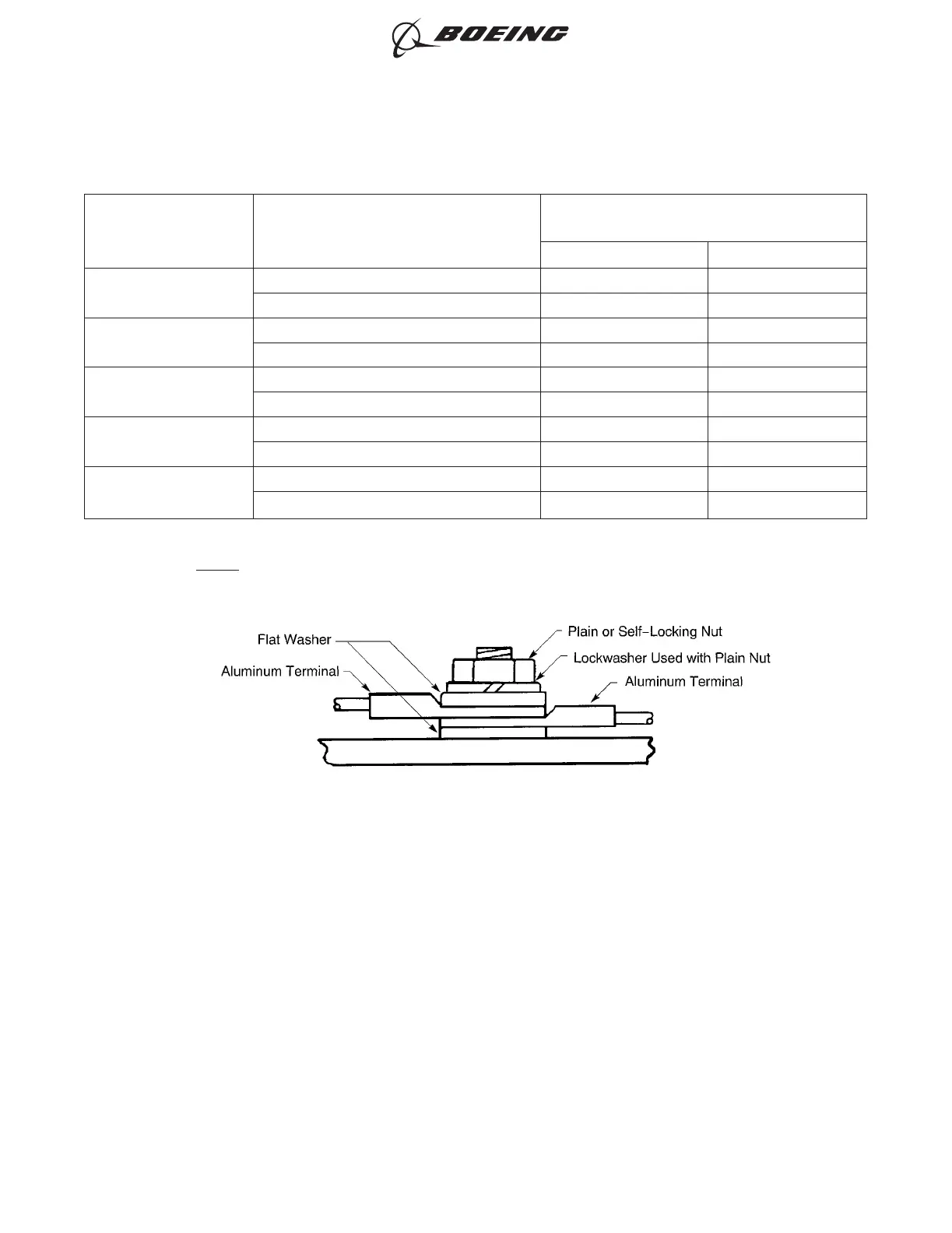

Table 7

INSTALLATION TORQUE FOR ALUMINUM TERMINALS

Stud Size Hardware

Torque

(inch-pound)

Minimum Maximum

10-()

Nut, Plain With Lockwasher 28 35

Nut, Self-Locking 33 40

1/4-()

Nut, Plain With Lockwasher 70 85

Nut, Self-Locking 75 90

5/16-()

Nut, Plain With Lockwasher 125 155

Nut, Self-Locking 135 165

3/8-()

Nut, Plain With Lockwasher 180 210

Nut, Self-Locking 220 250

1/2-()

Nut, Plain With Lockwasher 380 440

Nut, Self-Locking 430 490

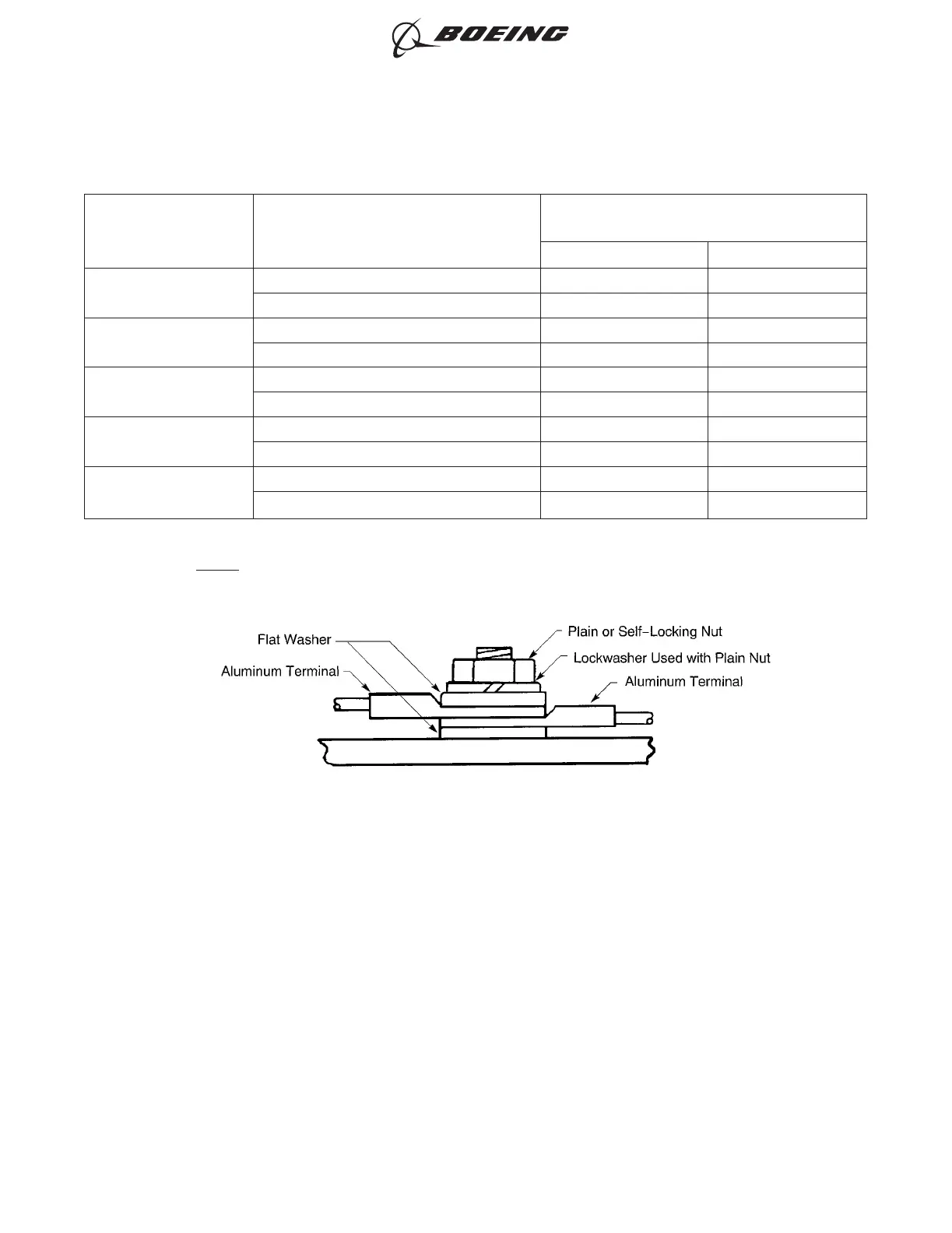

(1) Make a selection of a flat washer from Table 6.

NOTE: 2 washers are necessary.

(2) Install one or more terminals. Refer to Figure 11.

(a) Put a flat washer on the stud against the terminal board or equipment.

(b) Put the terminal or terminals on the stud.

(c) Put the other flat washer on the stud against the top terminal.

(d) If a plain nut is used, put a lock washer on the stud against the last flat washer.

(e) Put the nut on the stud.

(f) Torque the nut. Refer to Table 7.

If the torque value is not specified in Table 7 for the terminal hardware, make sure that:

• The lock washer is fully compressed

• The terminal does not move on the stud.

POSITION OF THE WASHERS WITH ALUMINUM TERMINALS

Figure 11

ELECTRICAL CONNECTION OF EQUIPMENT AND INSTALLATION OF TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-00

Page 16

Feb 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...