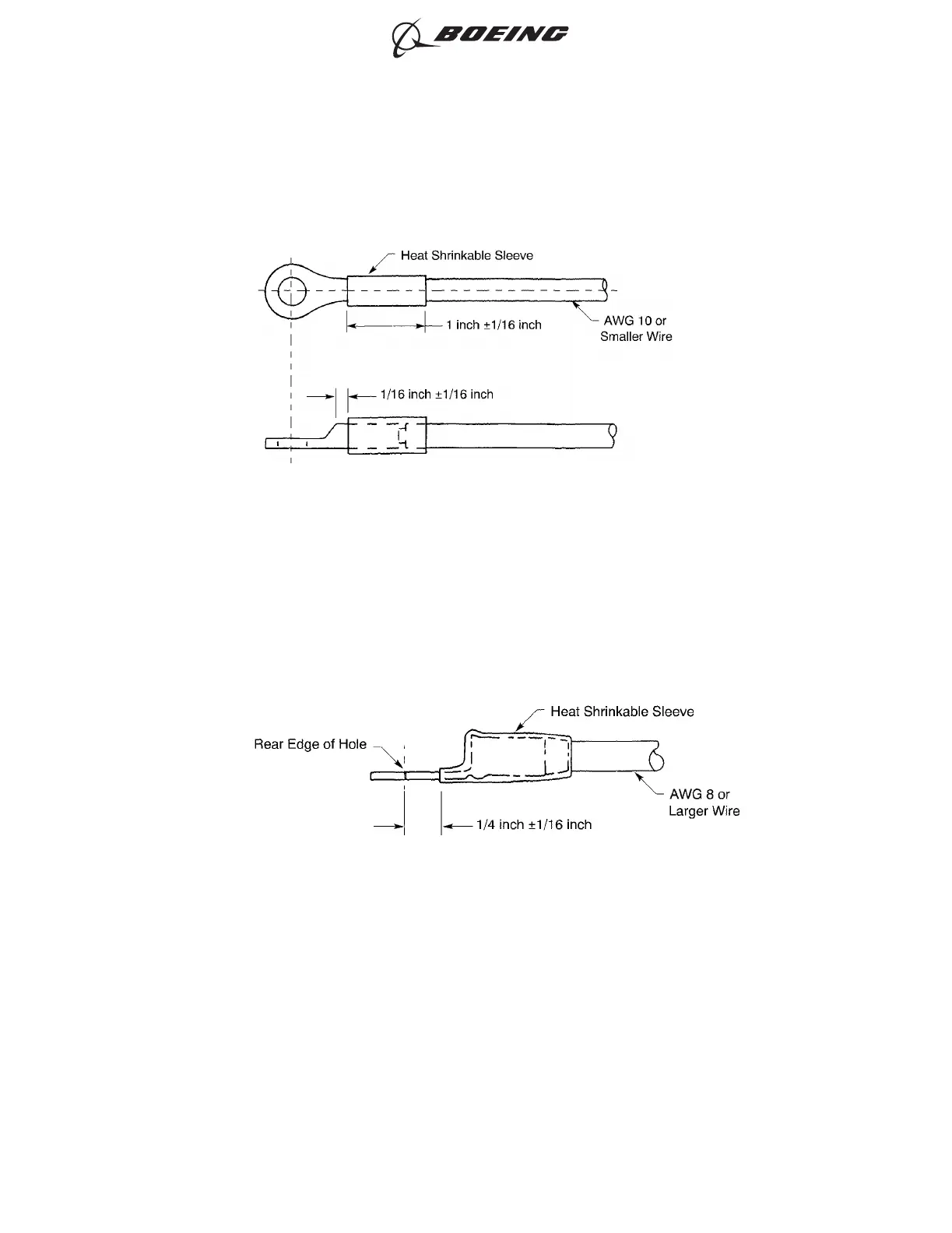

(b) For terminal lugs on AWG 8 or larger wire, push the sleeve over the terminal lug until the

end of the sleeve is 1/4 inch ±1/16 inch from the rear edge of the stud hole. Refer to Figure

27.

(c) Shrink the sleeve into its position.

(11) For a terminal lug in a high temperature area or in a high vibration area, if a heat gun cannot be

used:

(a) Make a selection of a Grade D TFE tape. Refer to Subject 20-00-11.

(b) Wind a sufficient number of layers of tape around the crimp barrel of the terminal and

around the end of the wire insulation.

Make sure that:

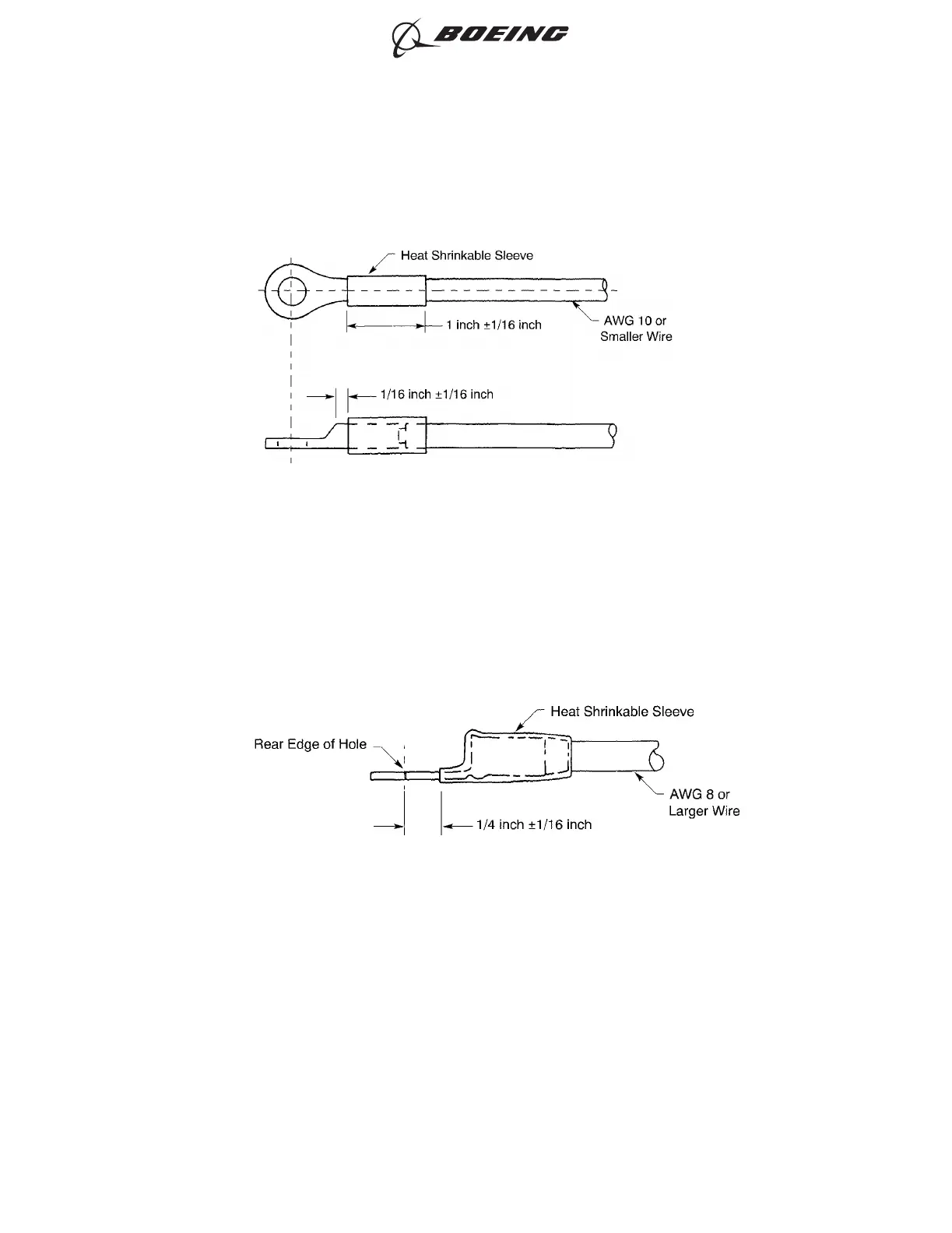

POSITION OF THE SLEEVE FOR SIZE AWG 10 OR SMALLER WIRE

Figure 26

POSITION OF THE SLEEVE FOR SIZE AWG 8 OR LARGER WIRE

Figure 27

ASSEMBLY OF INSULATED AND UNINSULATED TERMINAL LUGS

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-11

Page 94

Oct 15/2017D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...