(4) Put the parallel splice in the crimp tool.

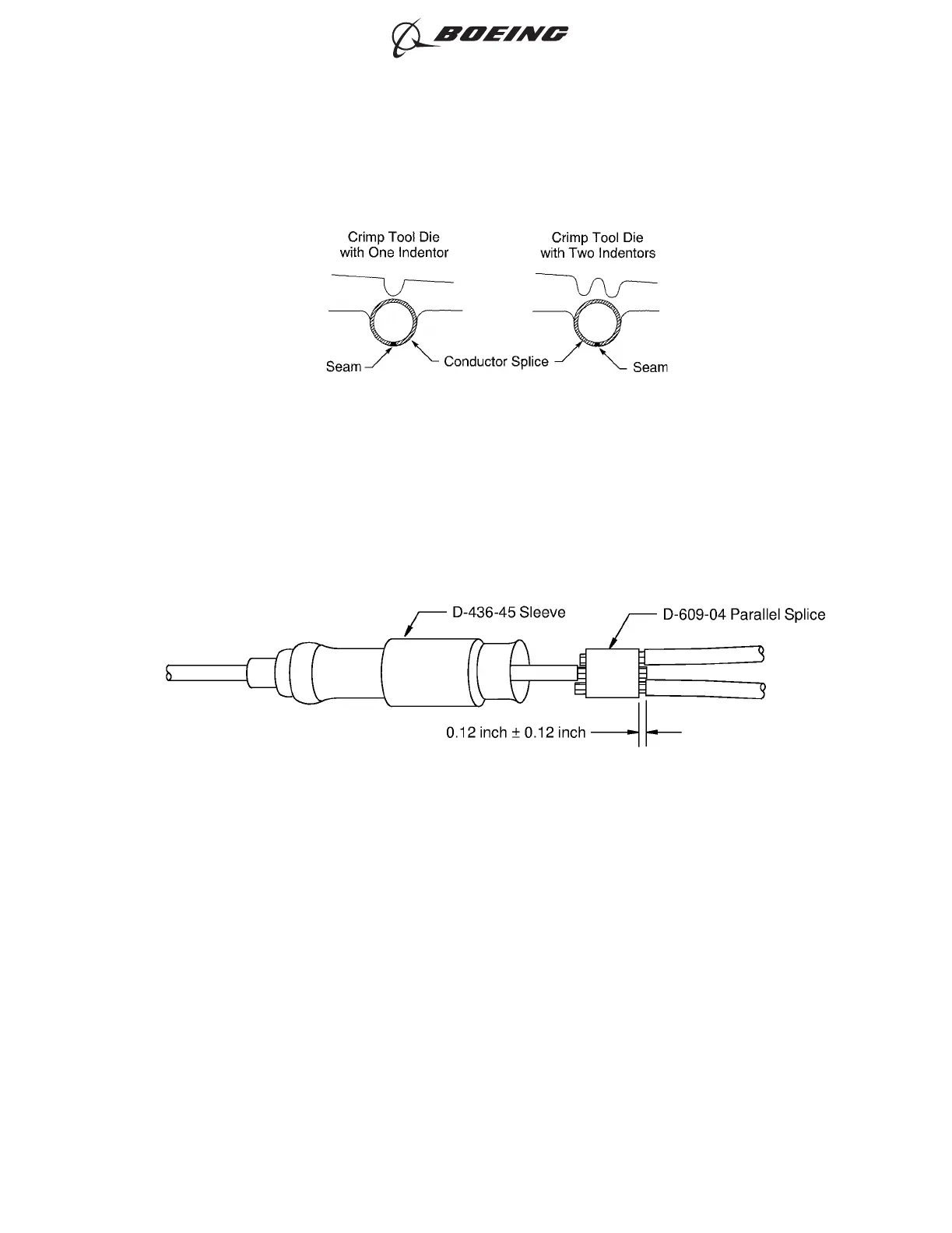

(5) If the splice has a seam, align the seam opposite the indenter. Refer to Figure 59.

(6) Hold the splice in position with light pressure.

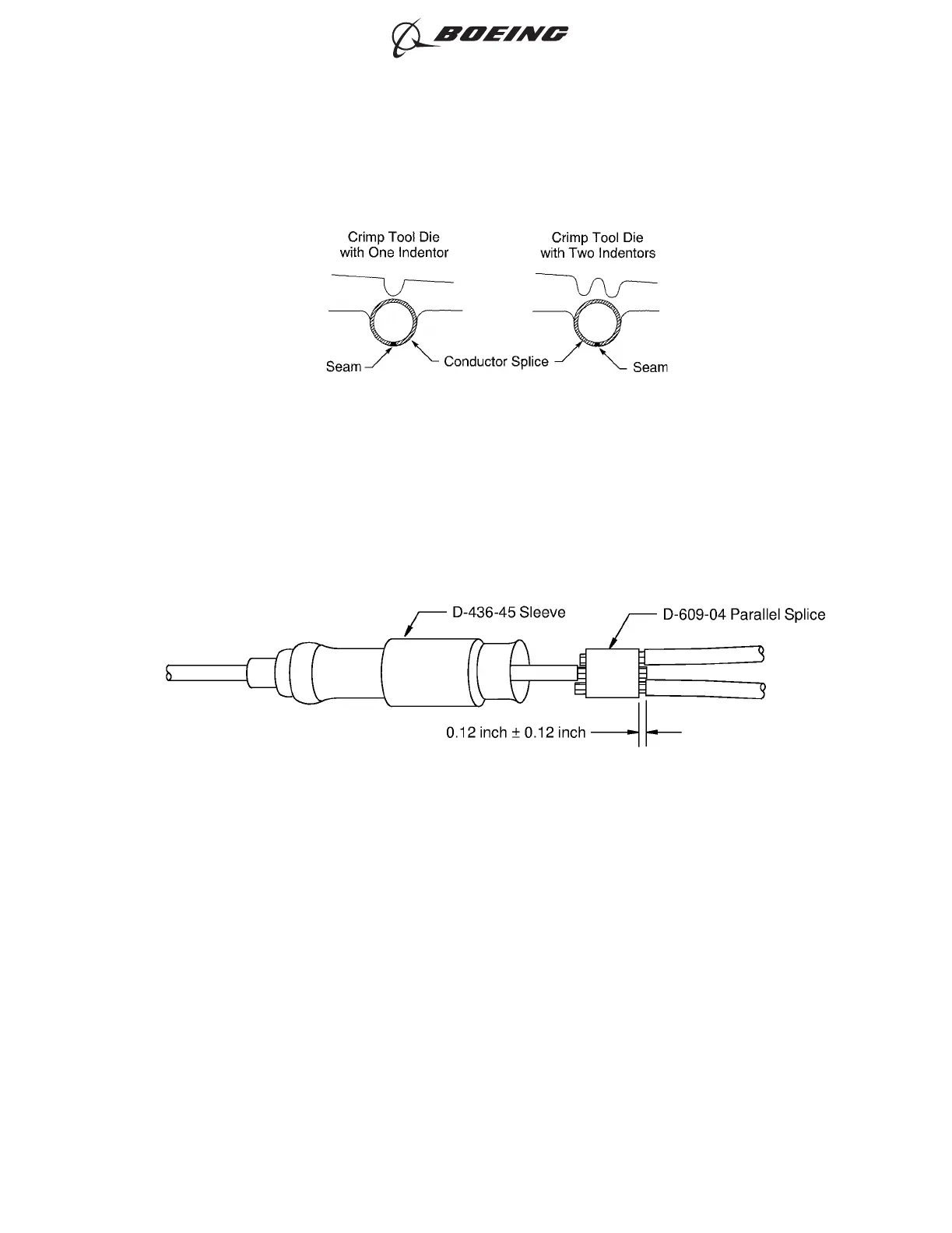

(7) Put the single wire in one end of the parallel splice and put the other two wires into the other end

of the splice. Refer to Figure 60.

Make sure that the distance from the end of the wire insulation to the edge of the parallel splice is

0.12 inch ±0.12 inch.

(8) Crimp the splice.

(9) Push the sleeve forward on the splice assembly.

Make sure that the large part of the sleeve is aligned with the center of the parallel splice.

(10) Shrink the sleeve into its position.

Refer to:

• Figure 61

• Subject 20-10-14.

POSITION OF THE PARALLEL SPLICE IN THE CRIMP TOOL

Figure 59

POSITION OF EACH WIRE IN THE PARALLEL SPLICE

Figure 60

ASSEMBLY OF SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-12

Page 97

Feb 15/2021D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...