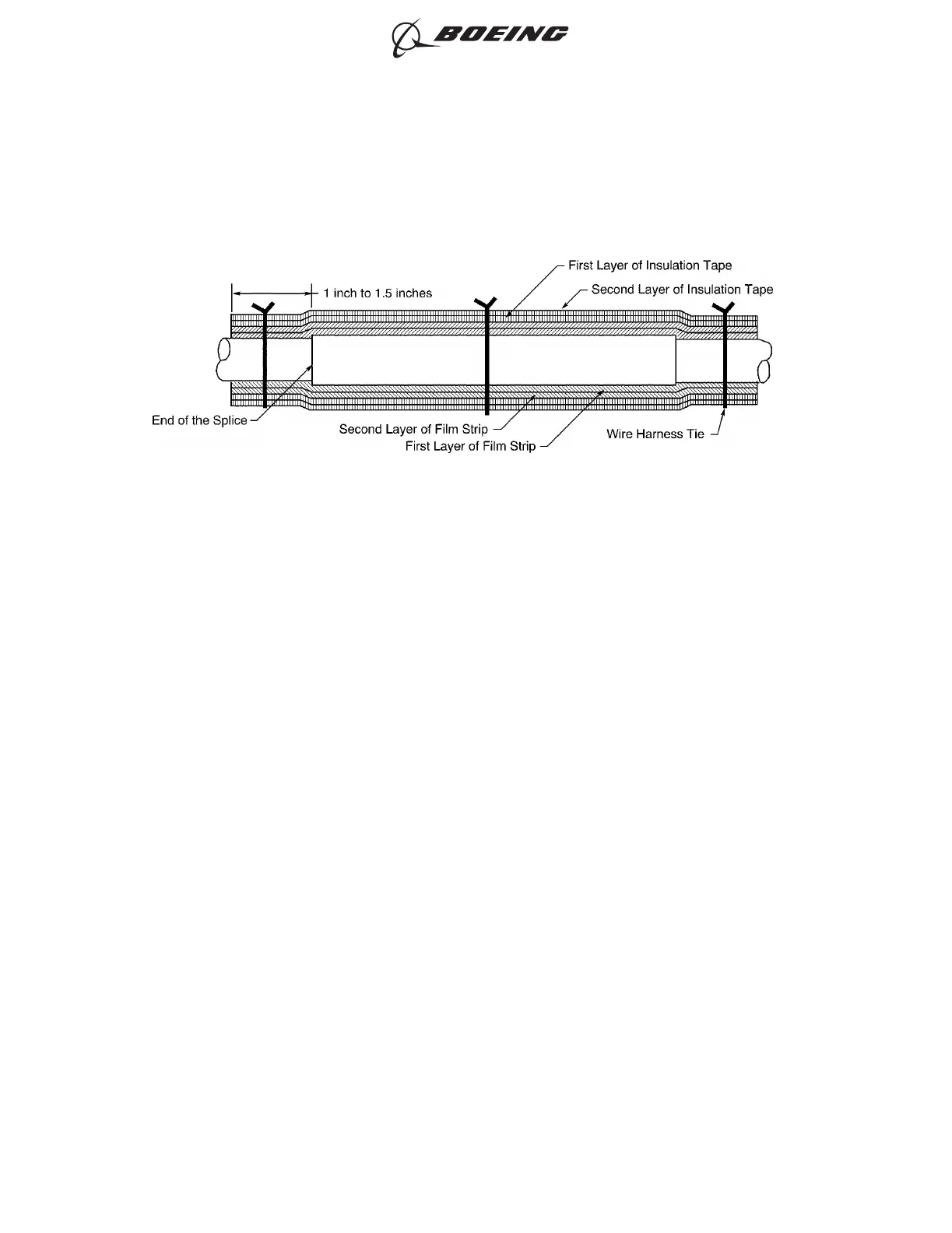

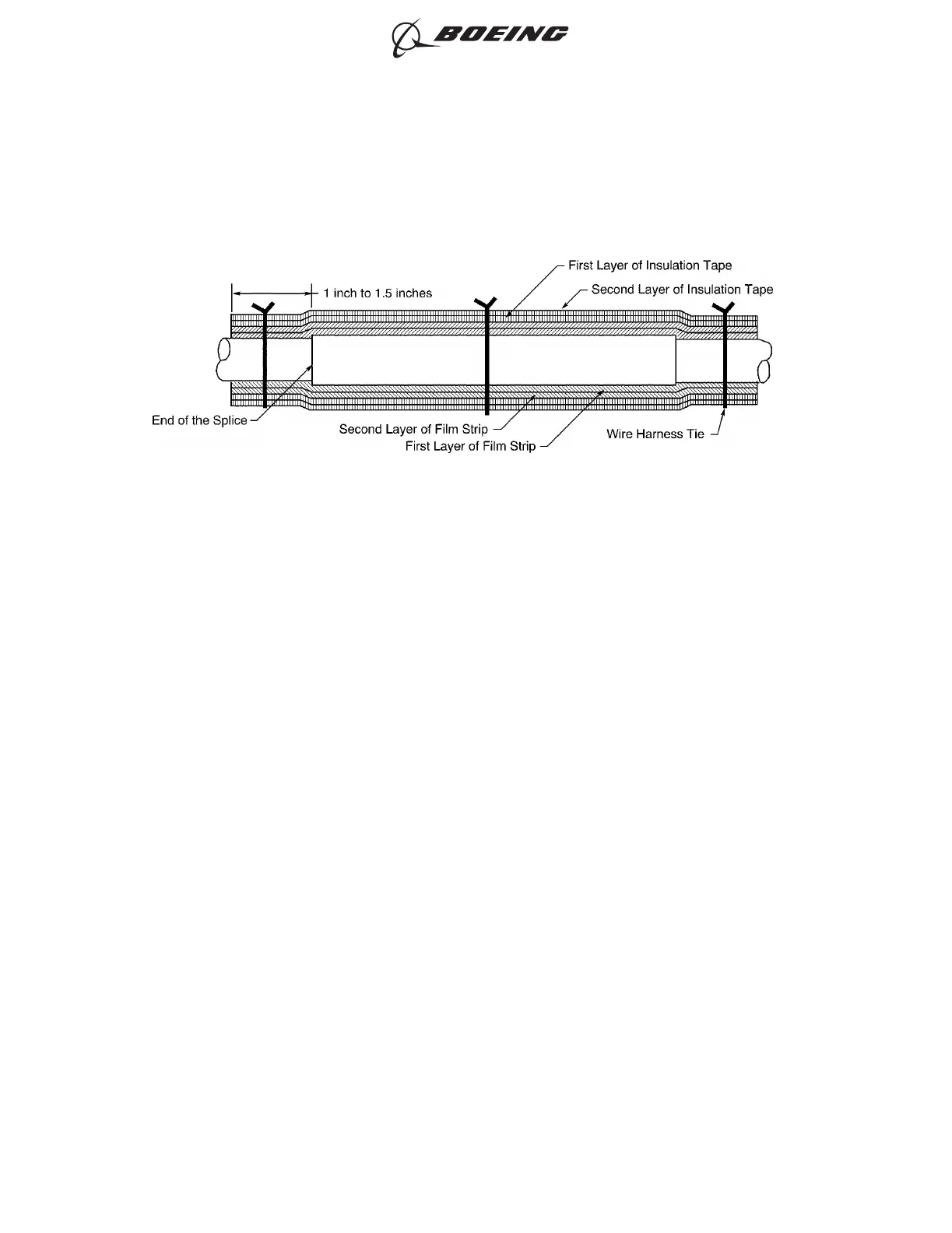

Refer to Figure 27.

(1) Make a selection of a solvent from Table 21.

(2) Make a selection of these materials from Table 21:

• A film strip

• An insulation tape.

(3) With a clean wiper and solvent, clean the splice assembly and the wire a minimum of 2 inches

farther than the end of the splice.

(4) Dry the cleaned area with a clean wiper.

(5) Wind two layers of film strip on the splice assembly.

(a) Start the first layer of tape one inch to 1.5 inches from the end of the splice.

(b) Wind the tape on the splice 1 to 1.5 inches farther than the other end of the splice.

Make sure that each edge of the tape makes a 50 percent overlap with the tape below it.

(c) Start the second layer of film strip where the first layer of film strip ends.

(d) Wind the tape on the first layer of tape in the direction of the start of the first layer of tape.

Make sure that:

• Each edge of the film strip makes a 50 percent overlap with the film strip below it

• The second layer of film strip is wound in the opposite direction of the first layer of film

strip

• The second layer of film strip ends where the first layer of film strip starts.

CONFIGURATION OF A SPLICE INSULATION REPAIR

Figure 27

ASSEMBLY AND REPAIR OF THE AMP AND BACS52N COPALUM SPLICES

707, 727-787

STANDARD WIRING PRACTICES MANUAL

20-30-13

Page 37

Oct 15/2015D6-54446

ECCN 9E991 BOEING PROPRIETARY - See title page for details

Loading...

Loading...